Water-rich sand-cobble stratum shield entry and exit reinforcing system and construction method thereof

A technology of sand and pebbles and access holes, which is applied to the reinforcement system of shield tunnels in water-rich sand and pebble strata and its construction field, can solve the problems of mechanical instability, poor gradation, and easy formation of cavities, etc. Safety, facilitate construction implementation, and reduce the effect of construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with specific embodiments.

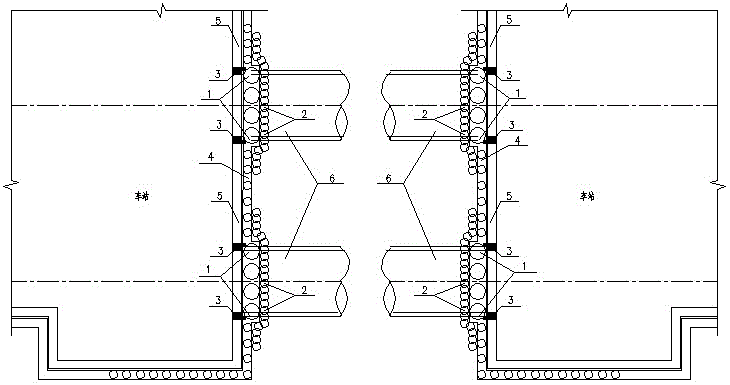

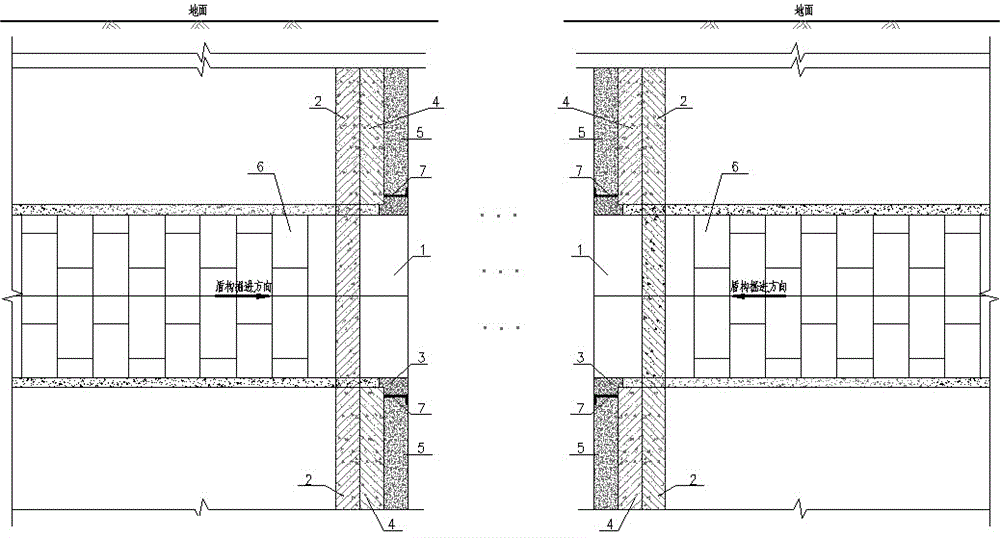

[0024] The invention relates to a reinforcement system for shield entry and exit holes in water-rich sand and pebble strata and a construction method thereof. System, to realize the reinforcement method of shield tunnel entry and exit holes in water-rich sand and pebble strata. This method adopts the reinforcement method of setting cuttable glass fiber reinforced retaining piles on the end wall of the station and adding a row of plain concrete occlusal piles on the periphery of the retaining piles, and cooperates with precipitation. This method works synergistically to form a continuous, rigid, and airtight support system, achieving the improvement effect of the previous reinforcement methods on the formation. Precipitation can improve the self-stabilization ability of the sand and pebble stratum, so as to achieve the purpose of effectively reinforcing the upper sand and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com