A Method for Evaluation of Object's Relative Distance Deviation

A technology of relative distance and evaluation method, applied in instruments, measuring devices, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as complexity, fatigue damage, affecting test and numerical accuracy, etc., to save production costs and improve test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

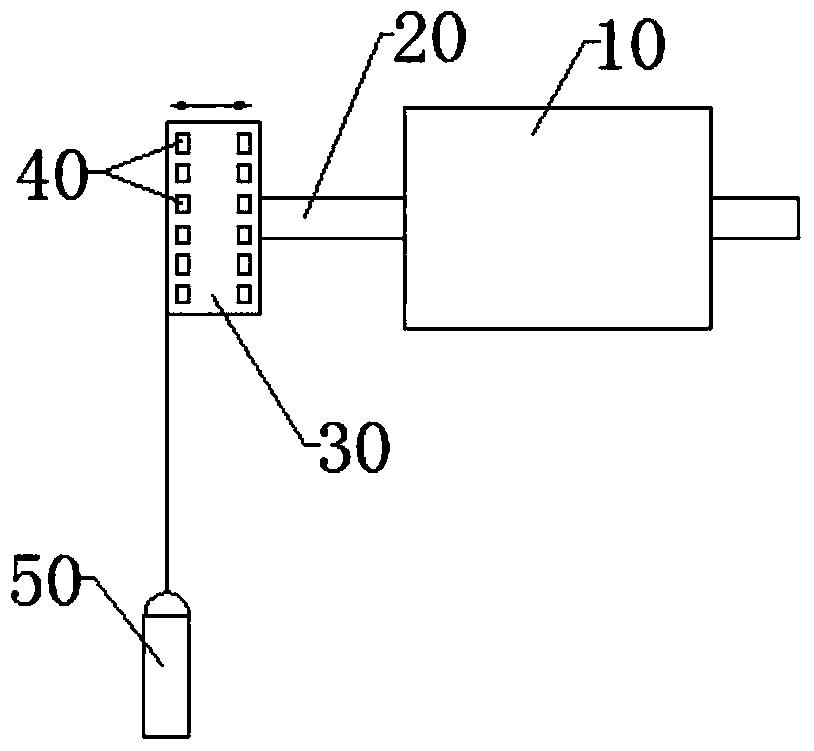

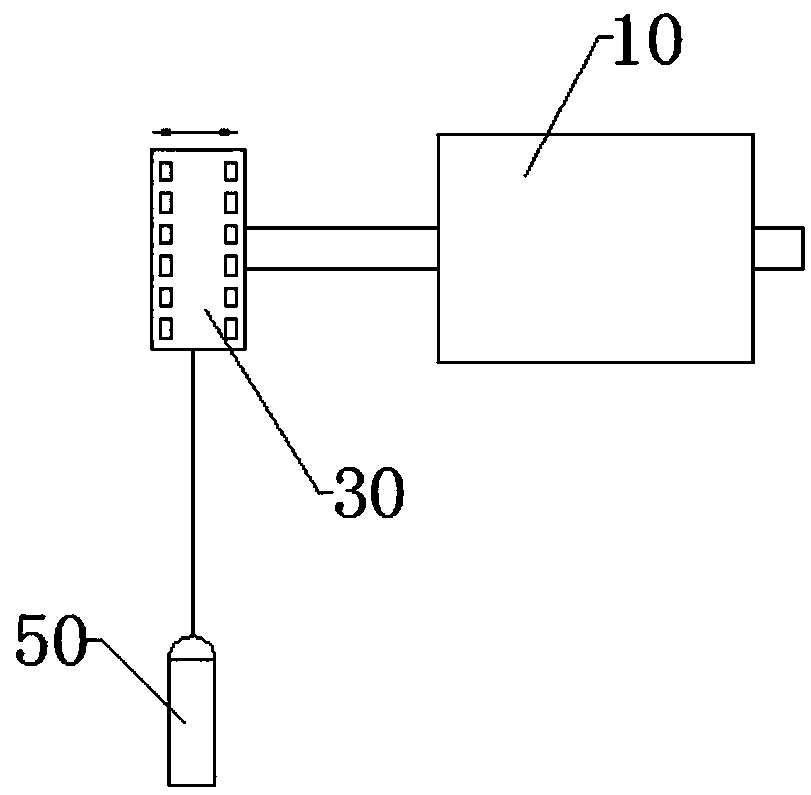

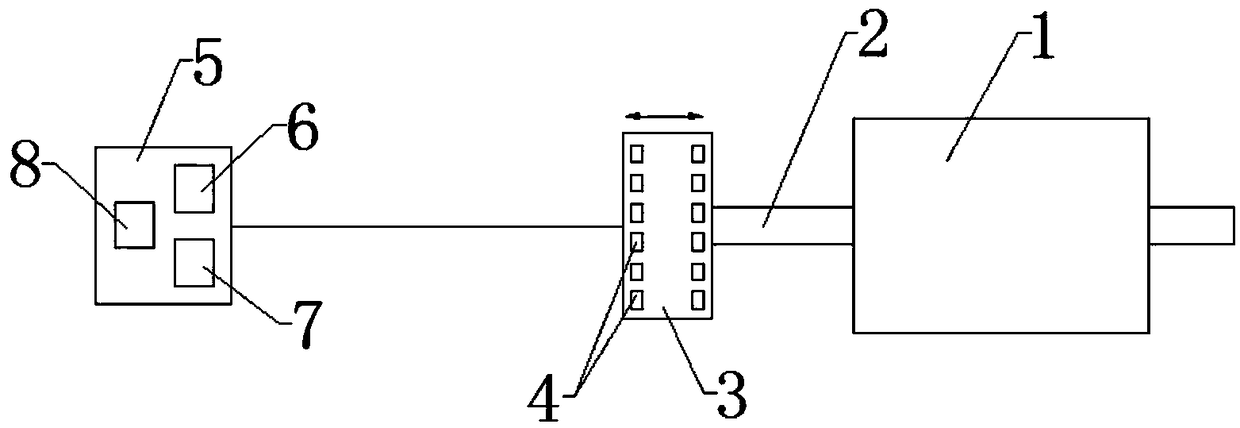

[0028] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended image 3 with Figure 4 The method for evaluating the object's relative distance deviation provided by the present invention is described in detail.

[0029] image 3 It is a schematic diagram of an embodiment of an evaluation method for a relative distance deviation of an object, Figure 4 It is a flow chart of an embodiment of an evaluation method for a relative distance deviation of an object, such as image 3 with Figure 4 As shown in , the method for evaluating the relative distance deviation of an object provided by the present invention is applied to the vibration relative distance deviation detection of the shock absorber 3 on the linear motor 1, and the end of the motor shaft 2 of the linear motor 1 is equipped with a shock absorber 3 A plurality of counterweights 4 are det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com