Full-automatic reciprocating type sandy soil sample preparing instrument

A sample preparation, reciprocating technology, applied in the preparation of test samples, etc., can solve the problems of insufficient guarantee of sample uniformity and sample preparation repeatability, insufficient motor control precision, low degree of sample preparation automation, etc., to achieve Improve the overall control accuracy, avoid the influence of manual operation, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

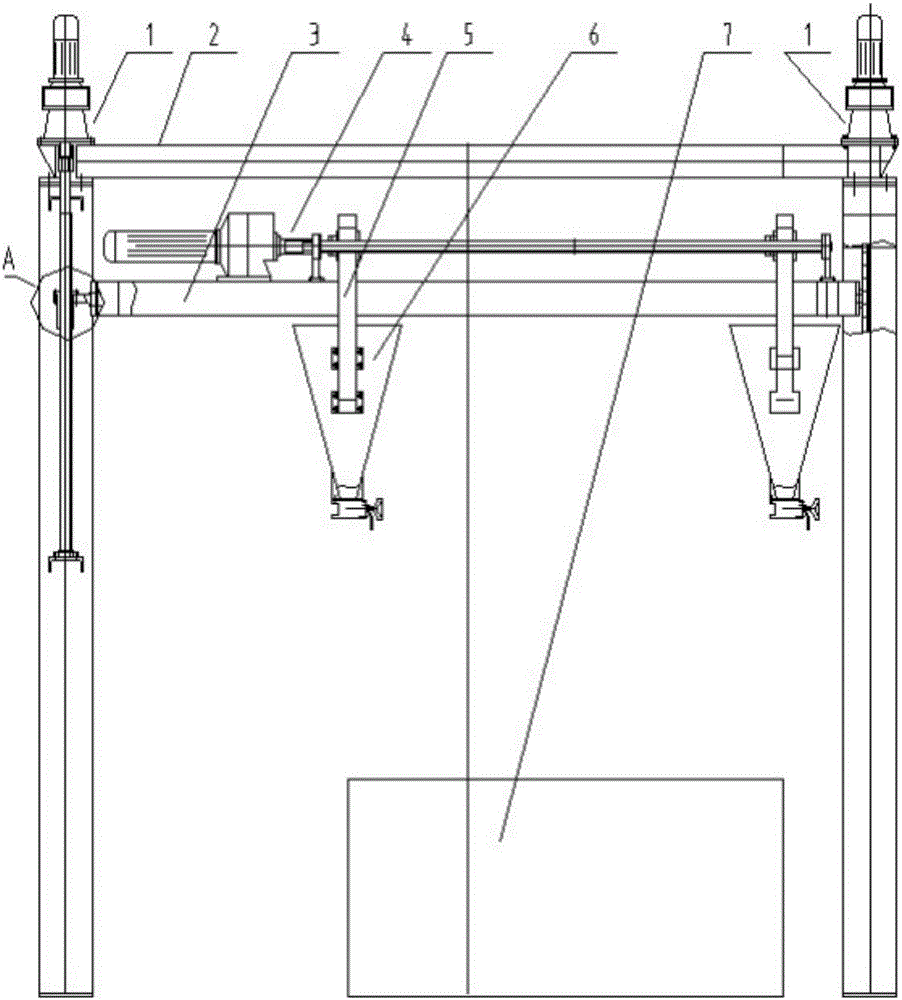

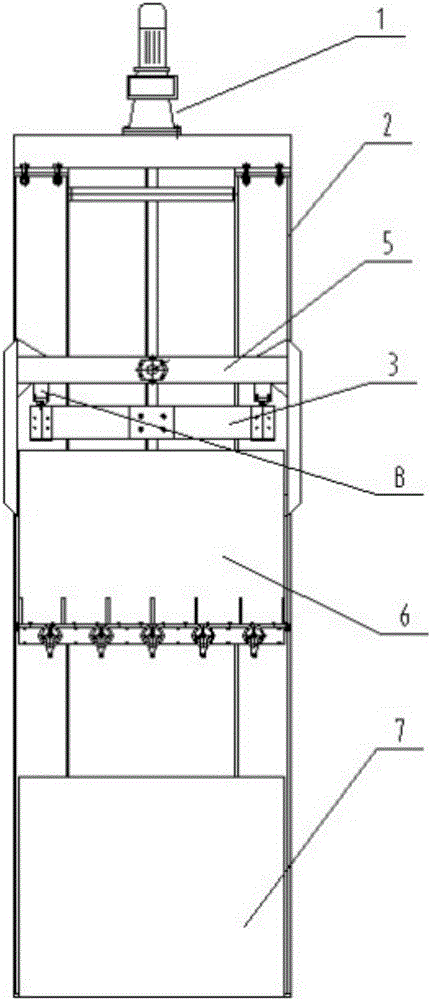

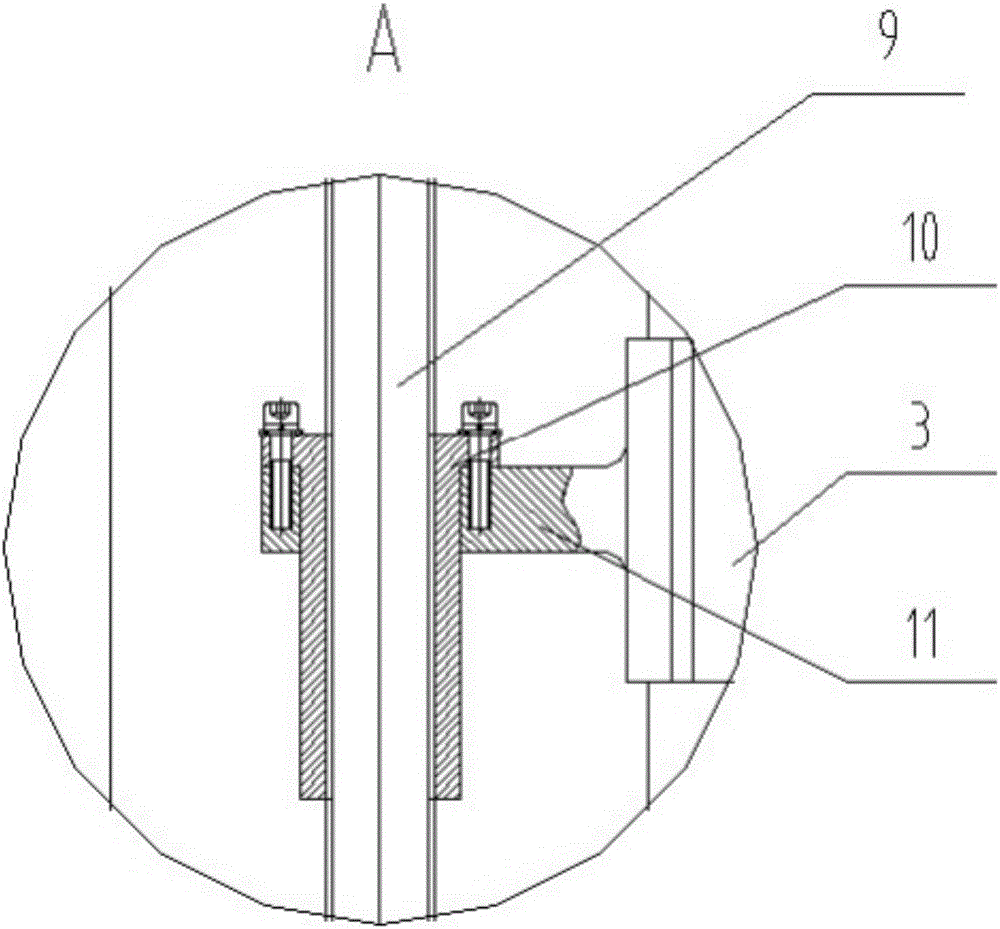

[0029] see Figure 1 to Figure 10 , a fully automatic reciprocating sand sample preparation instrument of the present invention, which includes a rigid frame 2, a vertical lifting system 1, a moving beam 3, a horizontal moving system 4, a guide assembly 8, a moving bracket 5, a funnel assembly 6, and a sand box 7. Range finder, control box and PLC programmable controller. The rigid frame 2 is a fixed beam supported by four columns. Two sets of vertical lifting systems 1 are respectively placed on both sides of the rigid frame 2. The vertical lifting system 1 The upper end is fixedly connected with the fixed crossbeam of the rigid frame 2, the lower end is hinged with the rigid frame 2, the movable crossbeam 3 is placed in the rigid frame 2, and both ends are fixedly connected with the vertical lifting system 1 respectively, and the horizontal moving sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com