Non-contact measurement method for surface discharge pulse peak of high-voltage insulator

A high-voltage insulator and creeping discharge technology, applied in the high-voltage field, can solve the problems of overlapping discharge points, unfixed observation distance of ultraviolet imagers, and difficulty in quantitative analysis of discharges, and achieve the effect of ensuring safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

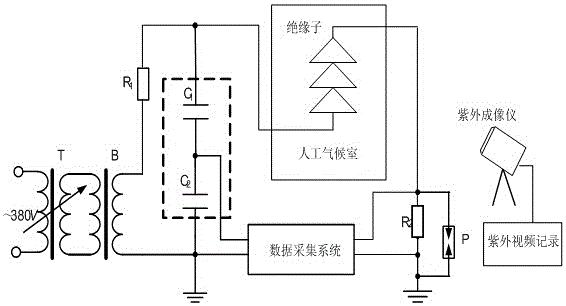

Method used

Image

Examples

Embodiment Construction

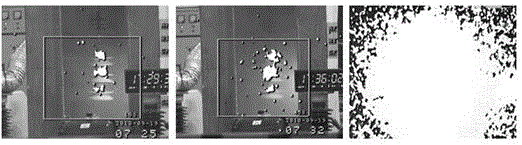

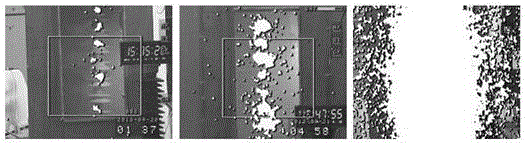

[0048]In the laboratory, the present invention takes the XWP2-70 insulator as the research object, and studies the ultraviolet image characteristics of 1 to 7 dirty insulator strings under different string lengths and discharge intensities, and obtains the three discharge forms of corona, spark and arc. A large number of ultraviolet images and corresponding electrical pulse signals. Research has found that although there is a spot overlap phenomenon on multiple insulators, the overlap has little effect on the transverse spot diameter of the insulators. Therefore, the present invention proposes to use the maximum transverse spot diameter of the ultraviolet image as the quantification parameter of the ultraviolet image, and proposes The relevant image processing algorithm was used to extract the above image parameters; the relationship between the maximum spot diameter and the peak value of the electrical pulse signal, and the variation characteristics of the spot diameter with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com