Diagnostic method for gas path faults of aero-engine based on sliding mode theory

A technology for aero-engine and fault diagnosis, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as huge engine maintenance and replacement costs, improve accuracy, enhance reliability, reduce false alarm rate and The effect of false negatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Taking the gas path fault diagnosis problem of a certain type of turboshaft engine as an example, the technical solution of the present invention will be described in detail in conjunction with the accompanying drawings:

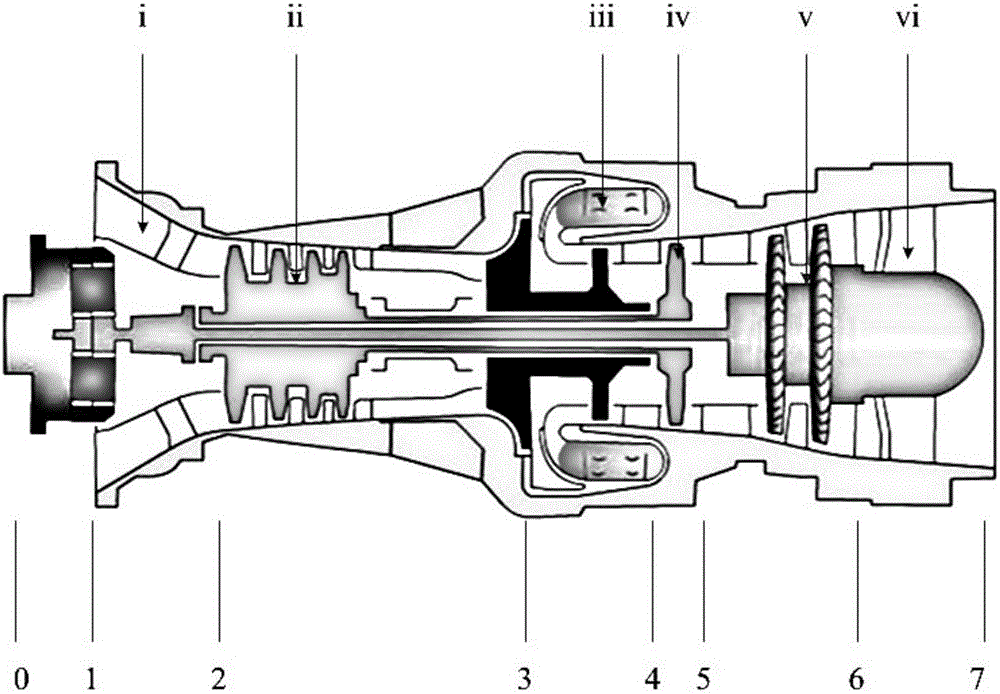

[0030] Such as figure 1 Shown is the structural diagram of the turboshaft engine, the turboshaft engine includes components: intake port i; compressor ii; combustion chamber iii; gas turbine iv; power turbine v; exhaust pipe vi; Disturbance section 0; inlet inlet section 1; inlet outlet section (compressor inlet section) 2; compressor outlet section (combustion chamber inlet section) 3; combustion chamber outlet section (gas turbine inlet section) 4; gas turbine Exit section (power turbine inlet section) 5; power turbine outlet section (tail nozzle inlet section) 6; tail nozzle outlet section 7;

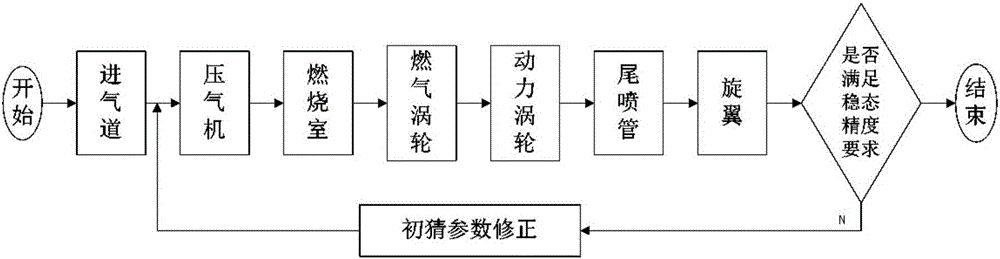

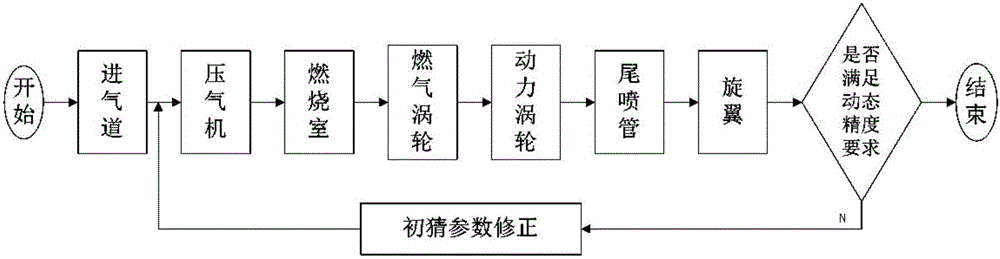

[0031] Step 1, according to the turboshaft engine structure figure 1 According to the component-level modeling method, the model of each component of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com