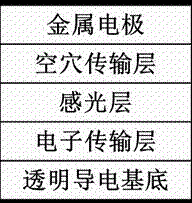

Preparation method of perovskite type solar cell modified by organic/inorganic hybrid hole transport layer

A hole transport layer and solar cell technology, applied in the field of solar cells, can solve problems such as poor energy conversion efficiency, poor stability, and poor visible light absorption rate, and achieve improved efficiency, increased air stability, and good photoelectric performance of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a perovskite solar cell modified by an organic-inorganic hybrid hole transport layer, the preparation steps are as follows:

[0024] (1) Dissolve methylammonium iodide and lead chloride in dimethylformamide at a molar ratio of 3:1, and stir for 5 hours to prepare a 30wt% perovskite precursor;

[0025] (2) Dilute 369 μL of titanium isopropoxide into 2.53 mL of isopropanol, add 35 μL of 0.026 mol / L hydrochloric acid aqueous solution into 2.53 mL of isopropanol, and mix the two solutions to prepare The titanium dioxide precursor solution is processed on the conductive transparent electrode by spin coating, inkjet printing or roll-to-roll printing, and then annealed in dry air at 500°C for 2 hours to obtain an electron transport layer with a thickness of 50nm;

[0026] (3) Process the perovskite precursor solution in (1) onto the electron transport layer in (2) by spin coating, inkjet printing, or roll-to-roll printing, and then anneal in nitrogen at ...

Embodiment 2

[0031] The difference between Example 2 and Example 1 is that the volume ratio of solution C and solution D in step (4) is 13.0%. The rest of the steps are the same.

Embodiment 3

[0033] The difference between Example 3 and Example 1 is that the volume ratio of solution C and solution D in step (4) is 16.7%. The rest of the steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap