Hydraulic suspension type cotton top-cutting machine

A technology of hydraulic suspension and topping machine, which is applied to agricultural machinery and implements, cutting tools, cutting equipment, etc., can solve the problems of inability to realize the immediate profiling of a single cotton plant, inaccurate adjustment of height, hitting peach, etc. The effect of cotton planting cost, reduction of equipment purchase cost, accurate identification and tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

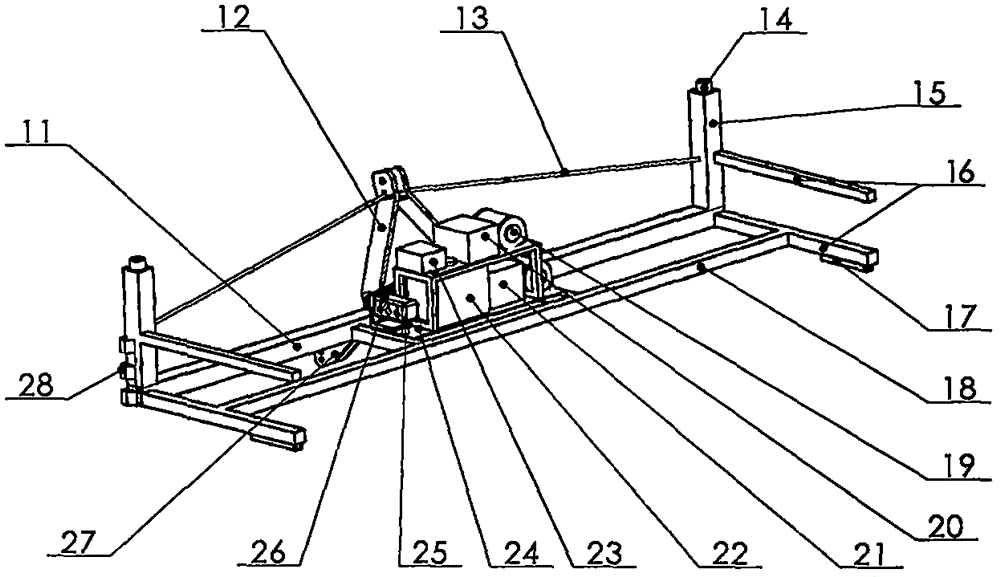

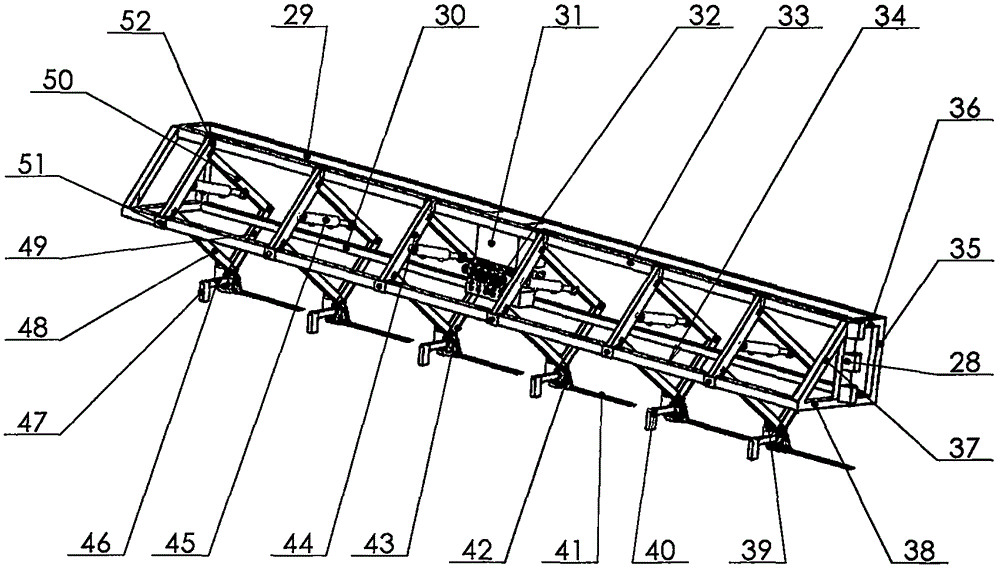

[0034] The structural principles and implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

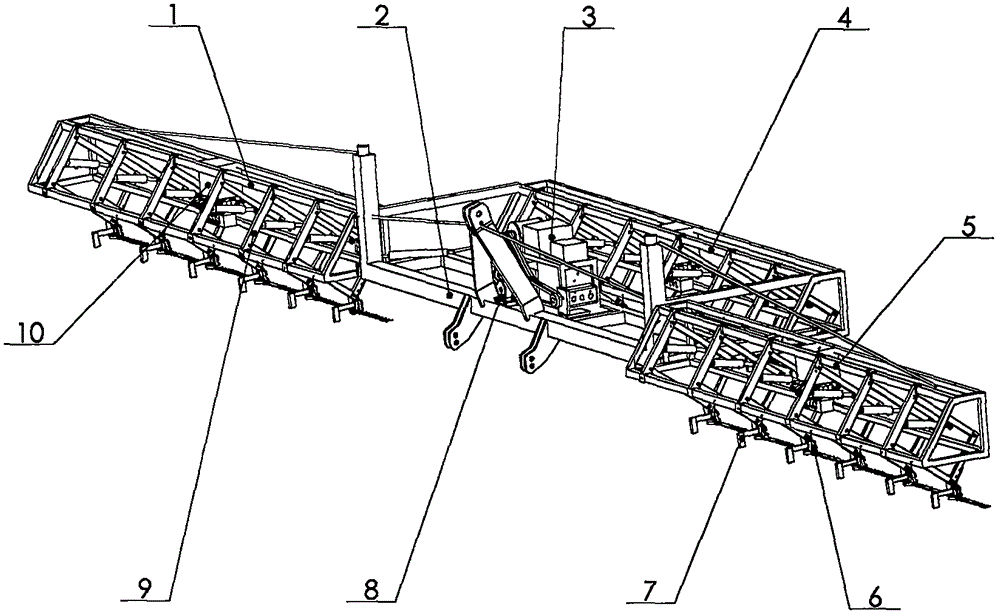

[0035] figure 1 Cotton topping machines in China are usually matched with tractors with rear suspension and power output shafts with high ground clearance (above 700mm). The number of rows of topping machines can be configured according to the power of the tractor. Multi-row and wide-width topping machines use The split truss structure can be folded on both sides. The overall height adjustment of the hydraulic suspension cotton topping machine is controlled by the rear suspension joystick of the tractor manually operated by the driver, and the height of the overall truss should be controlled at the height where the four-bar tracking mechanism 9 is in the middle of the full stroke and equal to the average plant height.

[0036] figure 1 The inclined beam planes of the split trusses 1, 4, and 5 of the cotton topping ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com