Numerical control drilling and milling machine with numerical-control multi-axis double working tables

A double-table, drilling and milling machine technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not being suitable for large-scale mass production, high cost, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

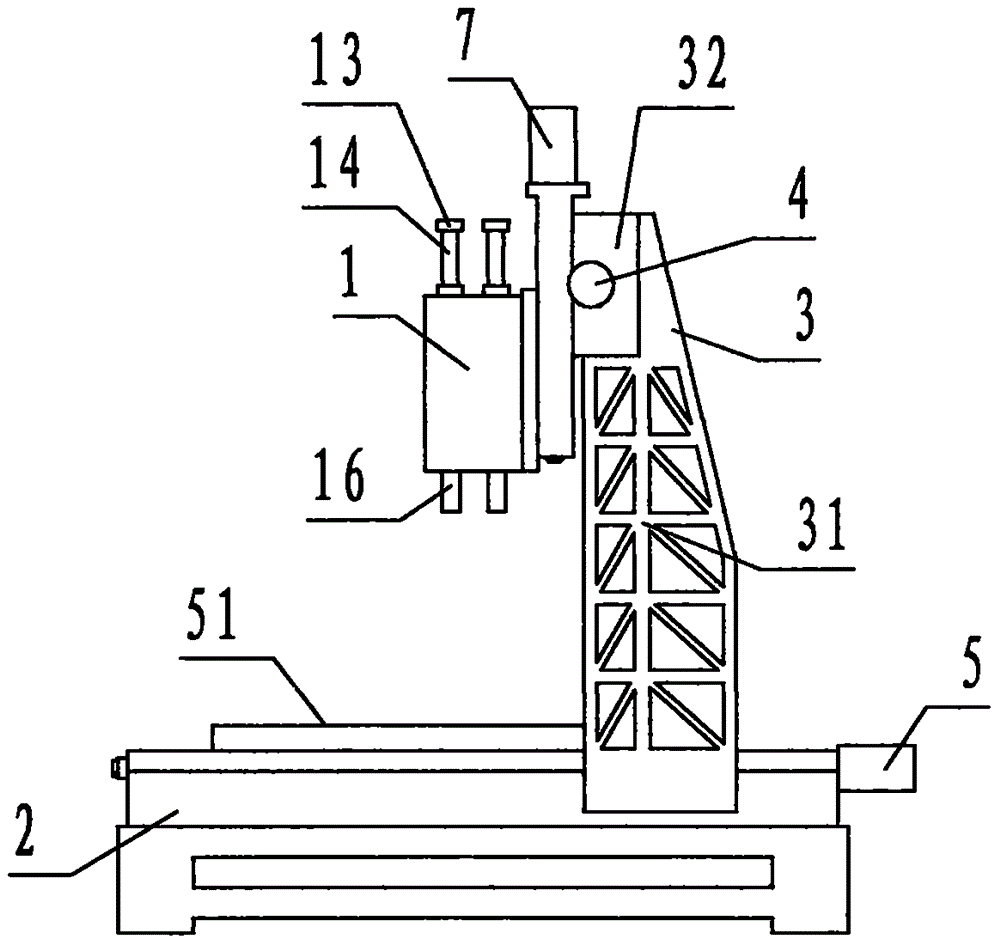

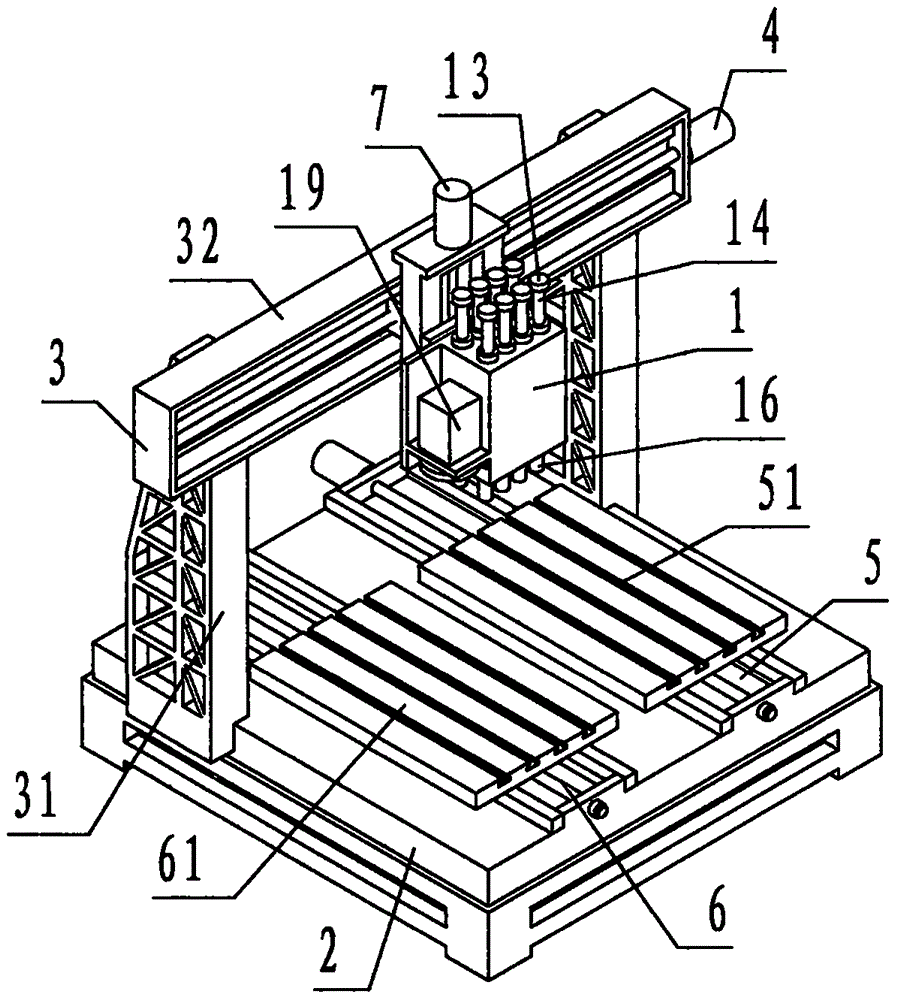

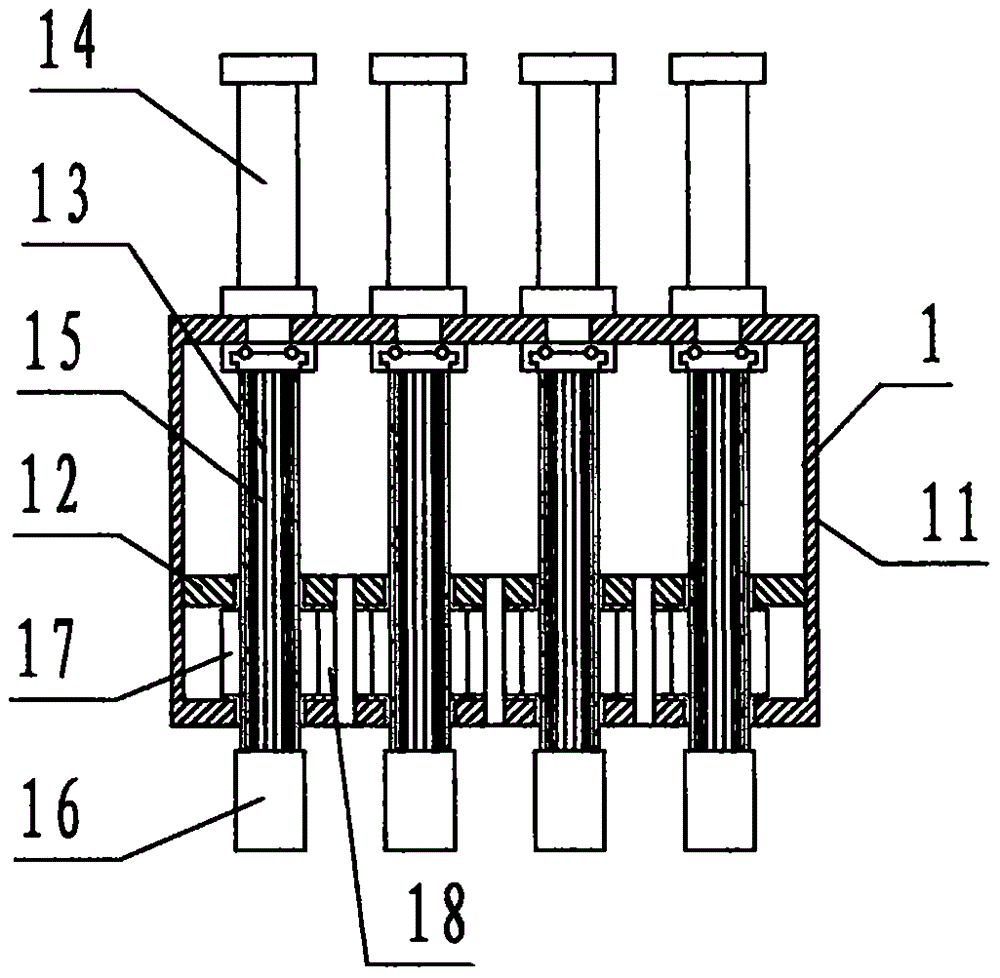

[0032] refer to Figure 1 to Figure 5 , a CNC drilling and milling machine with CNC multi-axis and double worktables of the present invention, comprising a CNC multi-axis box 1, a bed 2, a gantry 3, an X-axis unit 4, an AY-axis unit 5, a BY-axis unit 6, and a Z-axis unit 7 , wherein: the CNC multi-axis box 1 is composed of a box body 11, a bracket plate 12, a spindle motor 19 and a plurality of telescopic rotating shafts 13 arranged in an array, wherein the box body 11 is hollow and rectangular box-shaped Steel shell, the middle and lower part of the inner cavity of the box body 11 is provided with a steel isolation plate called the bracket plate 12; the bracket plate 12 isolates the inner cavity of the box body 11 into upper and lower layers, and the upper layer is called the key shaft warehouse, the lower floor is called the gear warehouse; the main shaft motor 19 is a motor with variable frequency speed regulation; A hydraulically telescopic actuator composed of a cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com