A centrifugal spinning nozzle for spinning sheath-core structure fibers

A technology of centrifugal spinning and skin-core structure, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc. It can solve the problems of not being able to generate skin-core structure spinning fibers, etc., and achieve the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

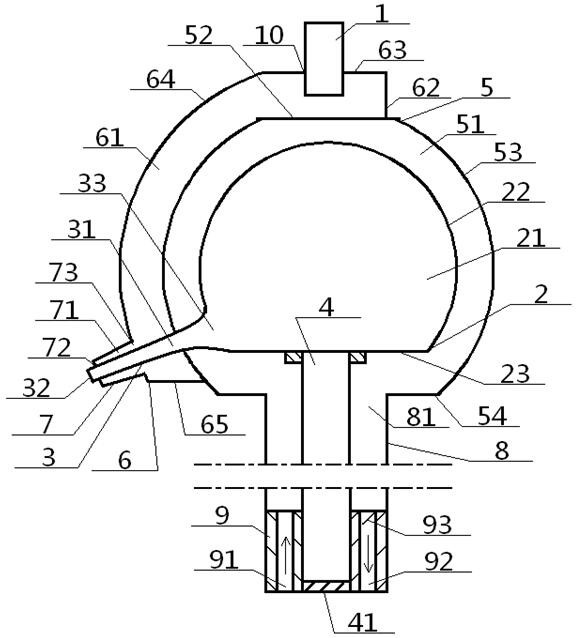

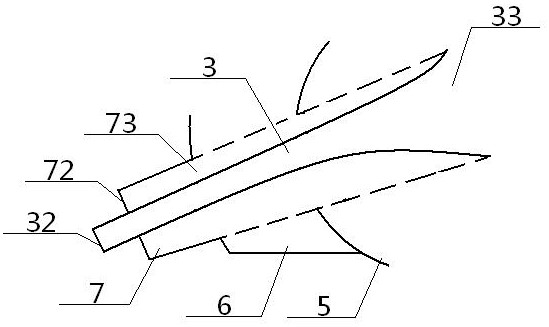

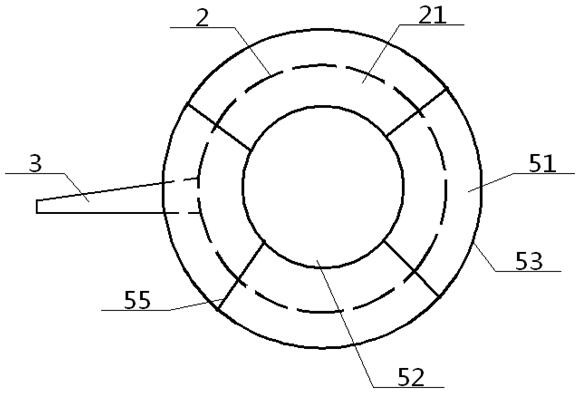

[0051] see Figure 1 to Figure 7 , a centrifugal spinning nozzle for spinning skin-core structure fibers, comprising an inner hollow shell 2, an inner spinneret tube 3 and an inner rotating tube 4, the inside of the inner hollow shell 2 is provided with an inner cavity 21, and the inner hollow shell 2 The side of the inner spinneret 3 is connected with the inner end of the inner hollow shell 2, and the bottom of the inner hollow shell 2 is connected with the top of the inner rotating tube 4; the centrifugal spinning nozzle also includes a middle sleeve body 5, an outer hollow shell 6, an outer The spinneret 7 and the outer rotating tube 8, the outside of the inner hollow shell 2 is covered with a middle sleeve body 5, and the top and left side of the middle sleeve body 5 are equipped with the same outer hollow shell 6. The inside of the shell 6 is provided with an outer cavity 61 in contact with the middle sleeve body 5, the side of the outer hollow shell 6 is connected with t...

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

[0054] The inner nozzle 32 protrudes outwardly relative to the outer nozzle 72 . Both the outer entrance 73 and the inner entrance 33 are arc-shaped structures, and the projection of the outer entrance 73 toward the inner entrance 33 is located on the same spherical surface as the arc surface where the inner entrance 33 is located. The top view structures of the inner spinneret 3 and the outer spinneret 7 are isosceles trapezoids with narrow outside and wide inside.

Embodiment 3

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] The inner hollow shell 2 includes an upper inner spherical shell 22 and an inner lower plate 23 connected up and down, and the middle sleeve body 5 includes a middle top plate 52 , a middle side ball circumference 53 , and a middle bottom plate 54 sequentially connected from top to bottom. , the outer hollow shell 6 includes an outer vertical plate 62, an outer top plate 63, an outer arc circumference 64, and an outer bottom plate 65 connected in sequence, and the bottom end of the outer vertical plate 62 is connected with the top surface of the middle top plate 52, The outer end of the outer bottom flat plate 65 is connected with the bottom of the outer arc circumference 64, the inner end of the outer bottom flat plate 65 is connected with the outer wall of the middle side spherical circumference 53, and the middle bottom flat plate 54 is vertically connected with the top of the outer rotating tube 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com