Energy-saving water purification machine

A pure water machine, energy-saving technology, applied in the direction of non-polluting water treatment, heating water/sewage treatment, etc., can solve the problems of high replacement cost, damage to public health, high energy consumption of pressurized filtration, etc., to achieve high quality and popularization The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

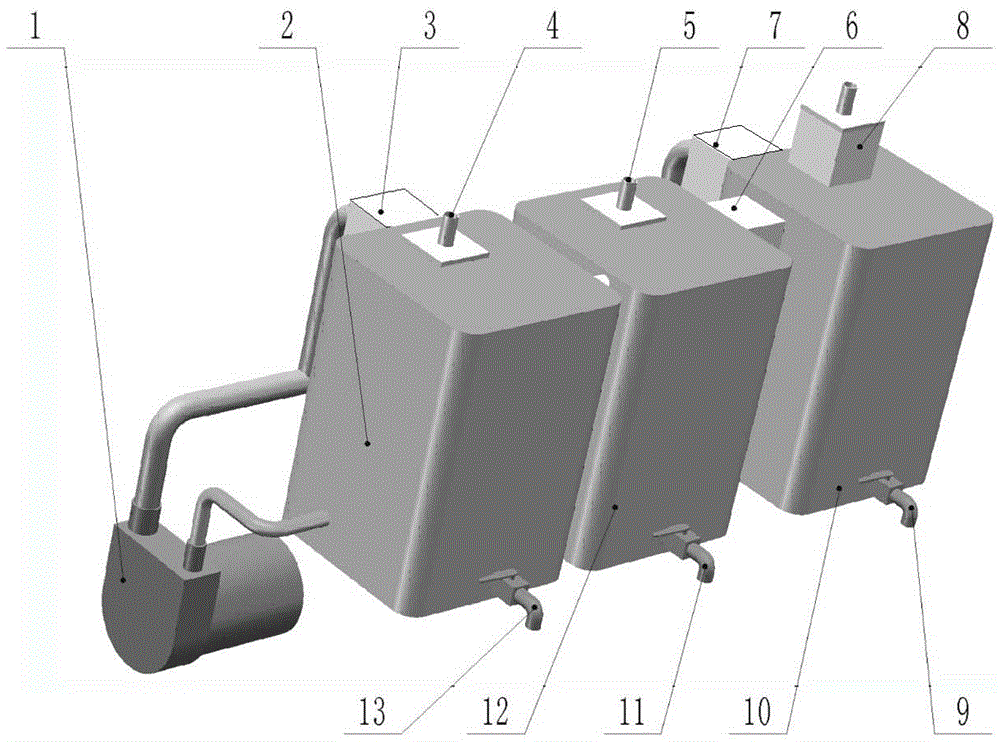

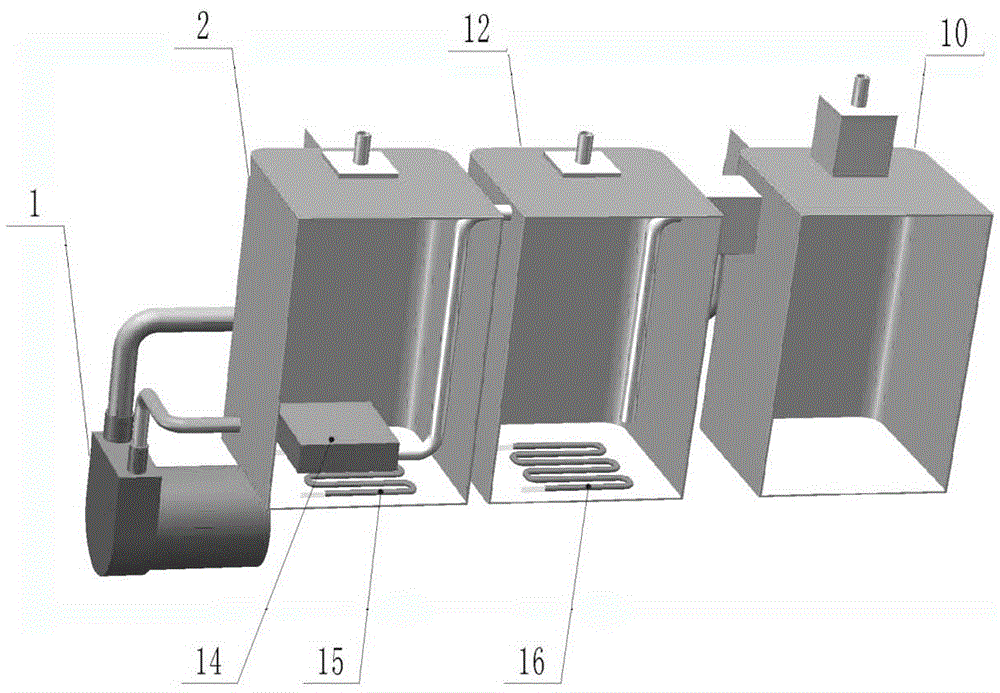

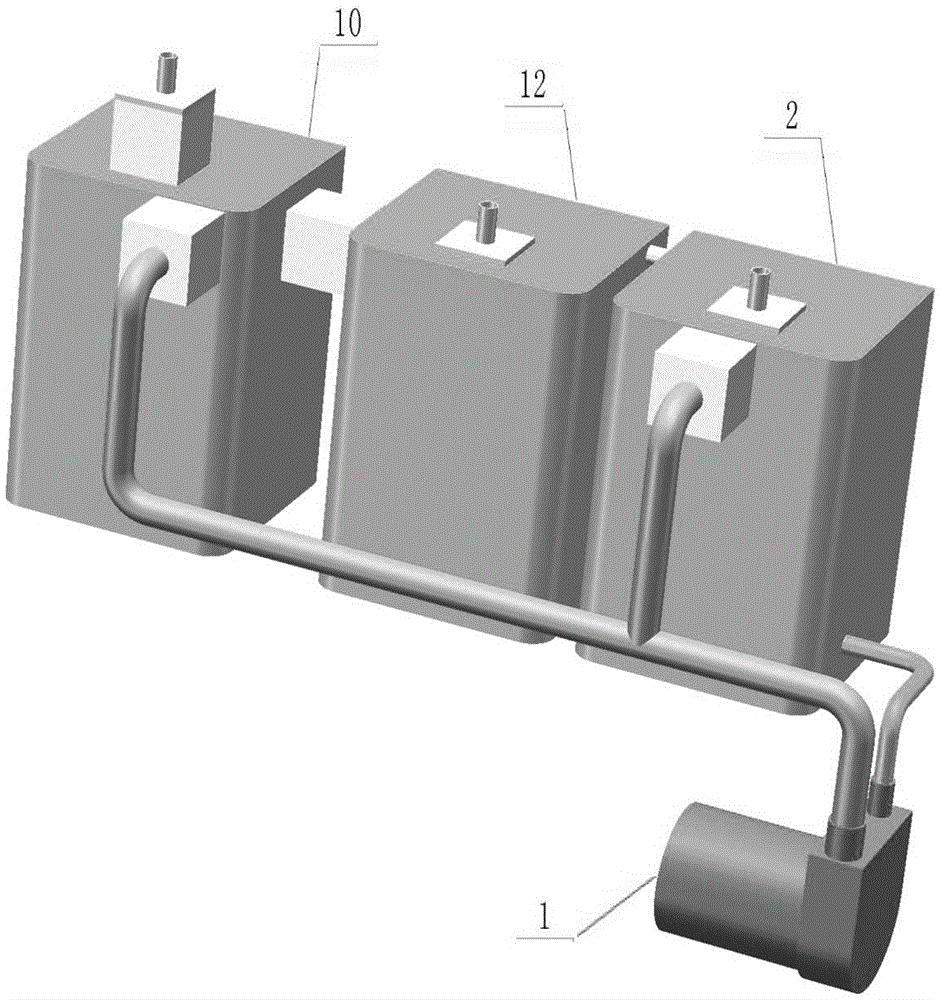

[0023] figure 1 and figure 2 It is a three-dimensional schematic diagram of an energy-saving pure water machine of the present invention. Set tap water inlet and steam outlet on the top and rear of the distillation tank respectively, set 1# electric heating tube inside, and set a heat exchanger on the top of the 1# electric heating tube; on the left and right sides of the distillation tank, set up a vacuum pump and hot water respectively 2# electric heating tube is installed inside the hot water tank, and an exhaust port is arranged on the top. The inlet pipe of the vacuum pump is connected to the steam outlet behind the distillation tank through the 1# solenoid valve, the outlet pipe of the vacuum pump is connected to the inlet pipe of the heat exchanger, and the outlet pipe of the heat exchanger is connected to the hot water tank. On the right side of the hot water tank, there is an ice water tank, and a steam outlet is set behind the ice water tank, and the inlet pipe of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com