Preparation method of magnesium L-threonate

A technology of magnesium threonate and reaction time, which is applied in the chemical industry and can solve the problems of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

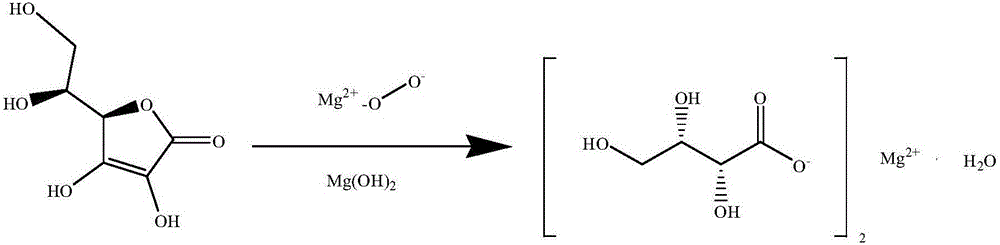

Image

Examples

Embodiment 1

[0022] Dissolve 0.1mol of vitamin C in 500ml of water, stir to dissolve at room temperature, control the temperature, add 0.06mol of magnesium hydroxide to neutralize, then add 0.25mol of magnesium peroxide; After adding peroxidase to the solution, react at a temperature of 35°C for 0.5h; filter with suction, concentrate the filtrate to thick, add 90% aqueous ethanol solution dropwise to the concentrated solution, and let it stand for crystallization under temperature control; filter with suction to obtain L- Magnesium threonate crystals weighed 12.54g after drying, with a yield of 65% and a purity of 98.5%.

Embodiment 2

[0024] Dissolve 0.1mol vitamin C in 500ml water, stir to dissolve at room temperature, control temperature, add 0.06mol magnesium hydroxide to neutralize, then add 0.20mol magnesium peroxide; keep stirring, react at room temperature for 6h; After the oxidase, react at a temperature of 35°C for 0.5h; filter with suction, concentrate the filtrate until thick, add 90% aqueous ethanol solution dropwise to the concentrated solution, and crystallize under temperature control; filter with suction to obtain magnesium L-threonate After drying, the crystal weighed 11.48g, the yield was 59.5%, and the purity was 97.2%.

Embodiment 3

[0026] Dissolve 0.1mol vitamin C in 500ml water, stir to dissolve at room temperature, control temperature, add 0.05mol magnesium hydroxide to neutralize, then add 0.30mol magnesium peroxide; continue stirring, control temperature at 50°C for 3.5h; After adding peroxidase to the solution, react at a temperature of 35°C for 0.5h; filter with suction, concentrate the filtrate to thick, add 95% aqueous ethanol solution dropwise to the concentrated solution, and let it stand for crystallization under temperature control; filter with suction to obtain L- Magnesium threonate crystals weighed 11.81g after drying, with a yield of 61.2% and a purity of 97.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com