Dry quenching waste heat recovery steam generator turbine steam admission/emission control method

A waste heat recovery and steam turbine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as large fluctuations in steam pressure, no consideration of steam turbine inlet and exhaust pressure, and stability interference of steam turbine power generation, so as to ensure stability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

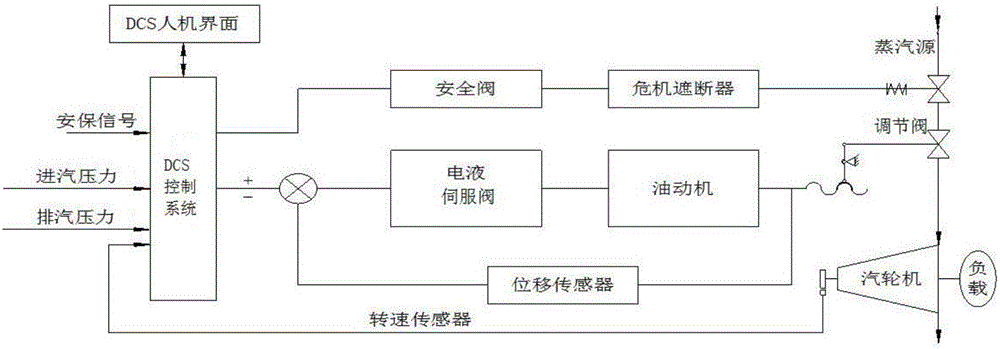

[0024] Such as figure 1 As shown, the CDQ waste heat recovery steam turbine inlet and exhaust steam control method of the present invention is characterized in that it comprises the following steps:

[0025] 1) The speed sensor collects the speed signal of the main shaft of the steam turbine, and transmits the speed signal to the DCS control system, and displays it as the monitoring value of the speed of the steam turbine;

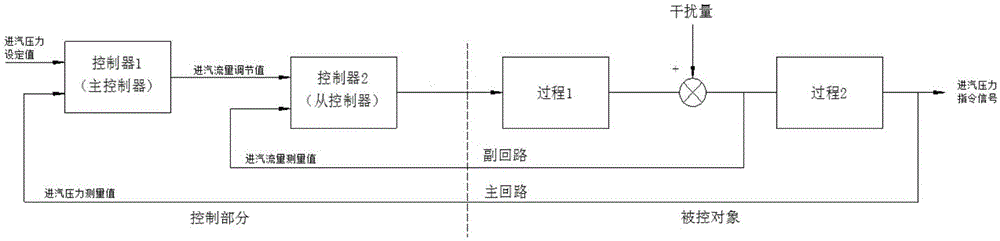

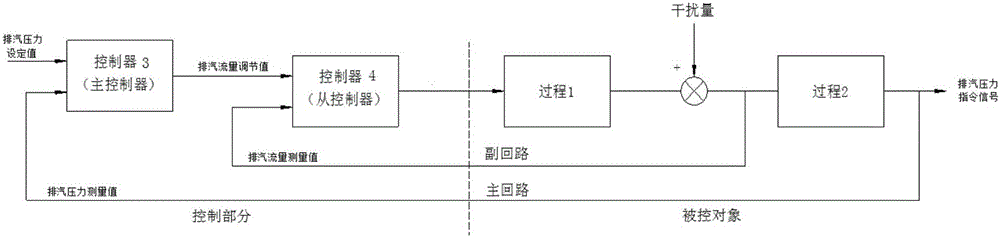

[0026] 2) if figure 2 As shown, the present invention carries out PID cascade adjustment to the inlet steam pressure of the steam turbine through the DCS control system; a double-loop control system is adopted, the main loop is the steam inlet steam pressure, and the secondary loop is the steam inlet steam flow; the specific process is:

[0027] The main loop compares the set value of the inlet steam pressure with the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com