System of low-temperature regeneration, drying and dehumidification for low-dew point drying room

A zone and wheel technology, applied in the field of drying and dehumidification devices, can solve the problems of high energy consumption and high initial cost, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

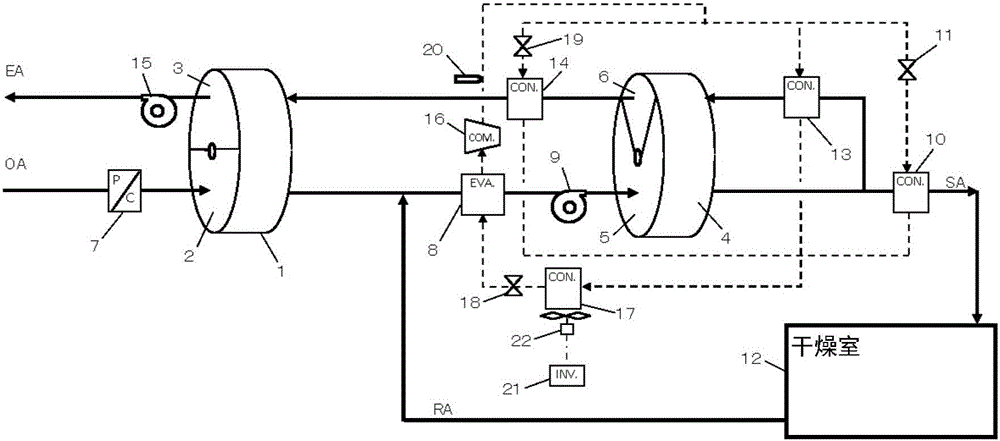

[0055] figure 1 It is a figure which shows the dehumidification apparatus of 1st Example of this invention. 1 is the first desiccant wheel, which is divided into the adsorption area 2 and the regeneration area 3. 4 is the second desiccant wheel, which is also divided into the adsorption area 5 and the regeneration area 6.

[0056] Reference numeral 7 denotes a first cooler (pre-cooler) for cooling and dehumidifying the outside air OA. That is, it is used to cool the air below the dew point of the outside air. The air passing through the first cooler 7, under the action of the first blower 9, after passing through the adsorption area 2 of the first dehumidification wheel 1, passes through the second cooler 8 (intercooler) and the second dehumidification wheel 4 Moreover, the temperature is adjusted by the first heater 10 (post-heater), and the air is supplied to the drying chamber 12 which is the supply destination of the dry air.

[0057] The return air RA from the drying c...

no. 2 example

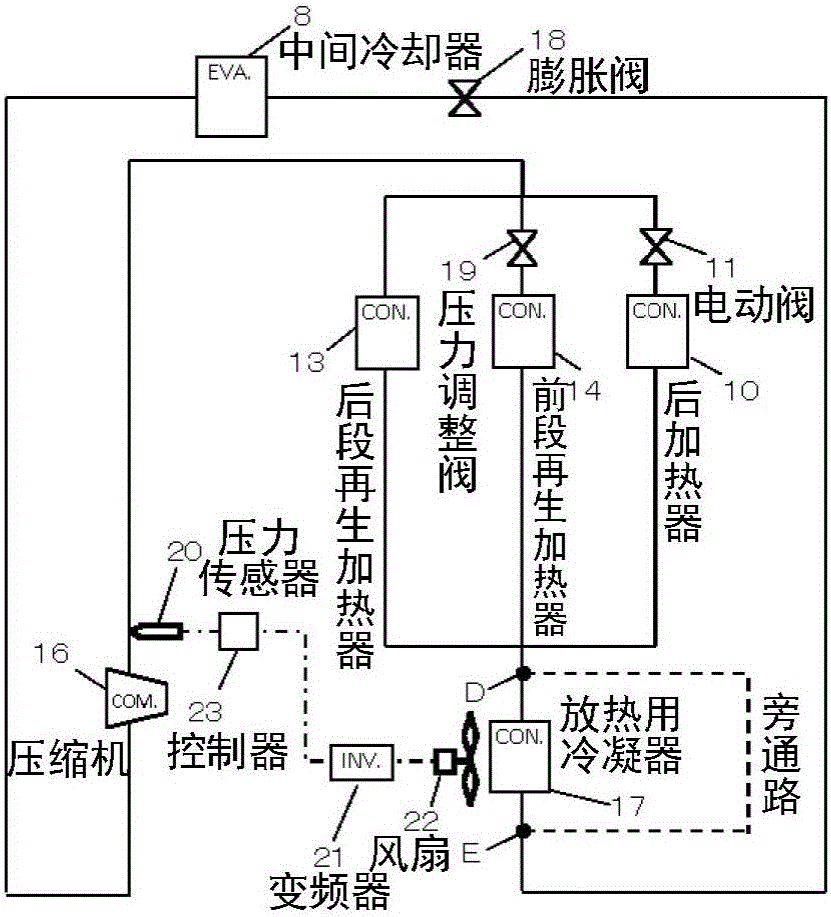

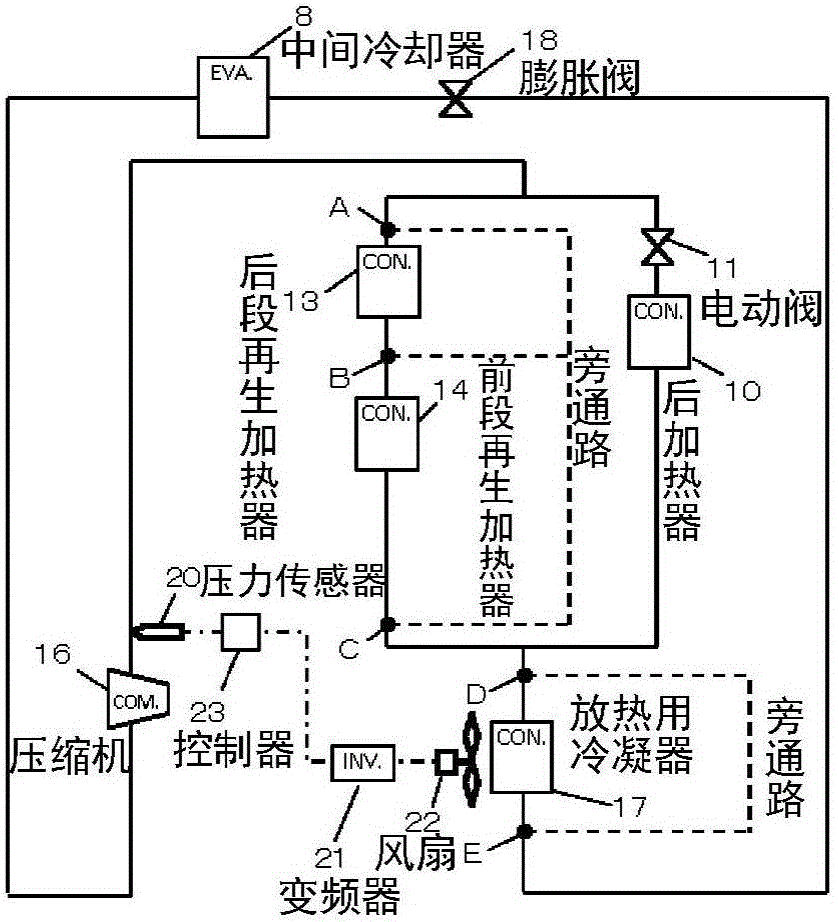

[0070] Figure 5 It is a figure which shows the dehumidification apparatus of the 2nd Example of this invention. In addition, the equipment structure of the dehumidification device and figure 1 The same as the first embodiment. also, Figure 6 is a diagram showing the flow of the refrigerant in the second embodiment. and figure 2 The refrigerant flow similarly, Figure 6The heat pump circuit of the embodiment is composed of compressor 16, evaporator for second cooler 8, 4 for first heater 10, second heater 13, third heater 14 and condenser 17 for heat release However, the evaporator for the first cooler 7 and the evaporator for the second cooler 8 are arranged in parallel. In addition, as a countermeasure against unstable operation due to low external air load and low refrigerant pressure as in winter, in order to enable stable operation of the refrigerant flow, the evaporator inlet from the condenser inlet side to the first cooler 7 Between the HIs on the side, a hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com