An elastic wheel torsion test tool

A technology of torsion testing and elastic wheels, which is applied in the direction of railway vehicle testing, etc., can solve the problems of deviation of torsional stiffness values, different torsional stiffness values, and difficulty in ensuring accuracy, etc., to achieve good compression effect, high precision, and convenient positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

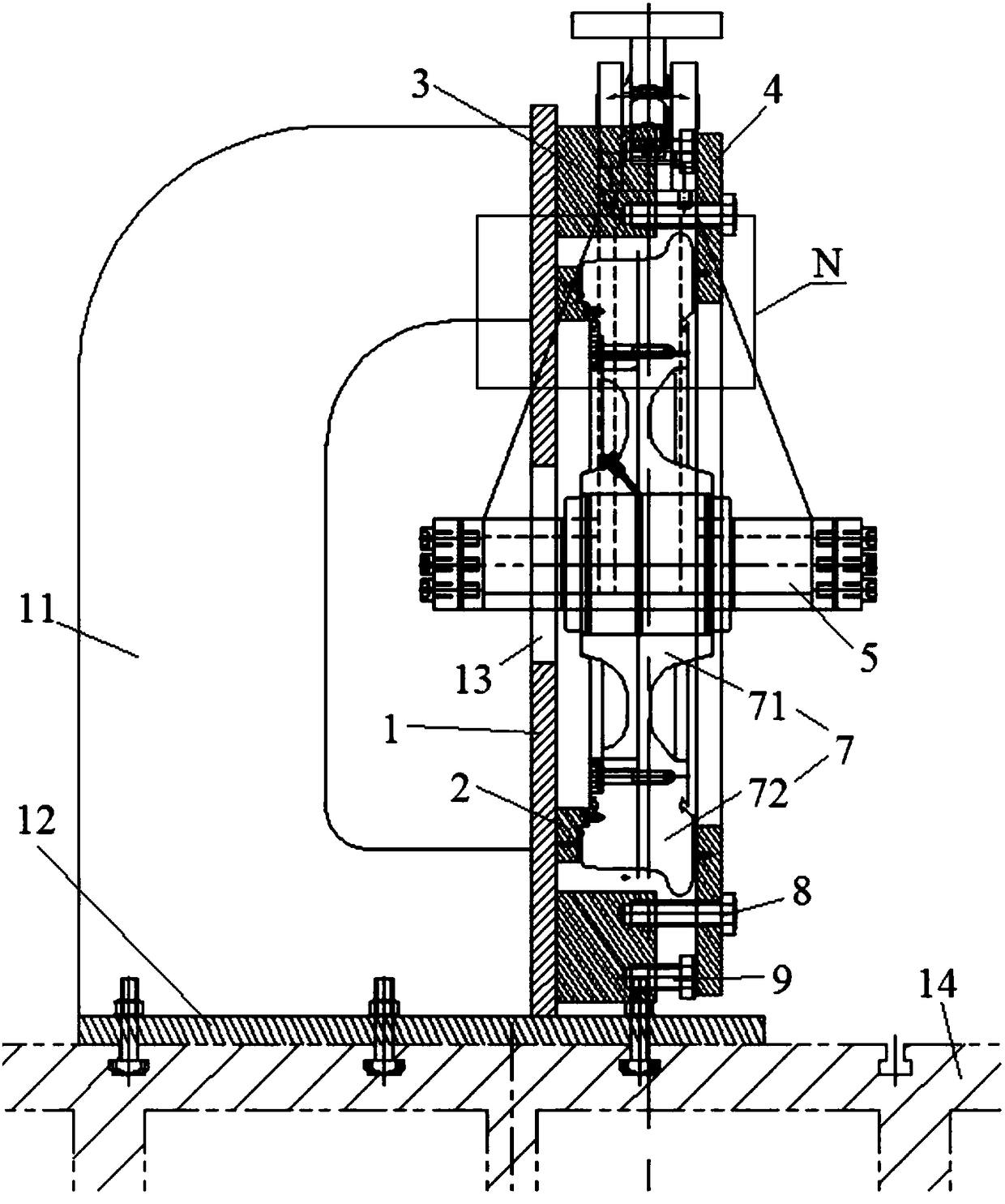

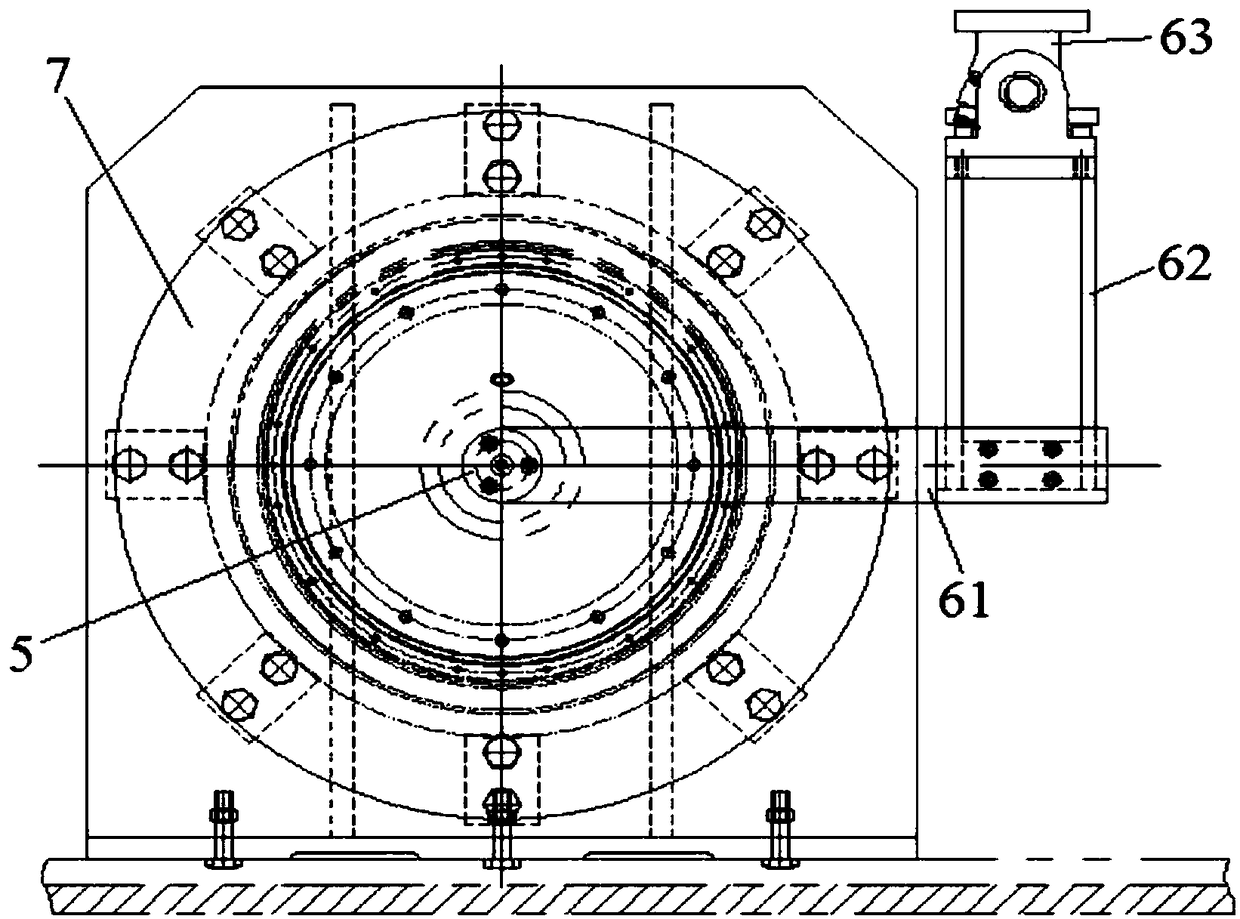

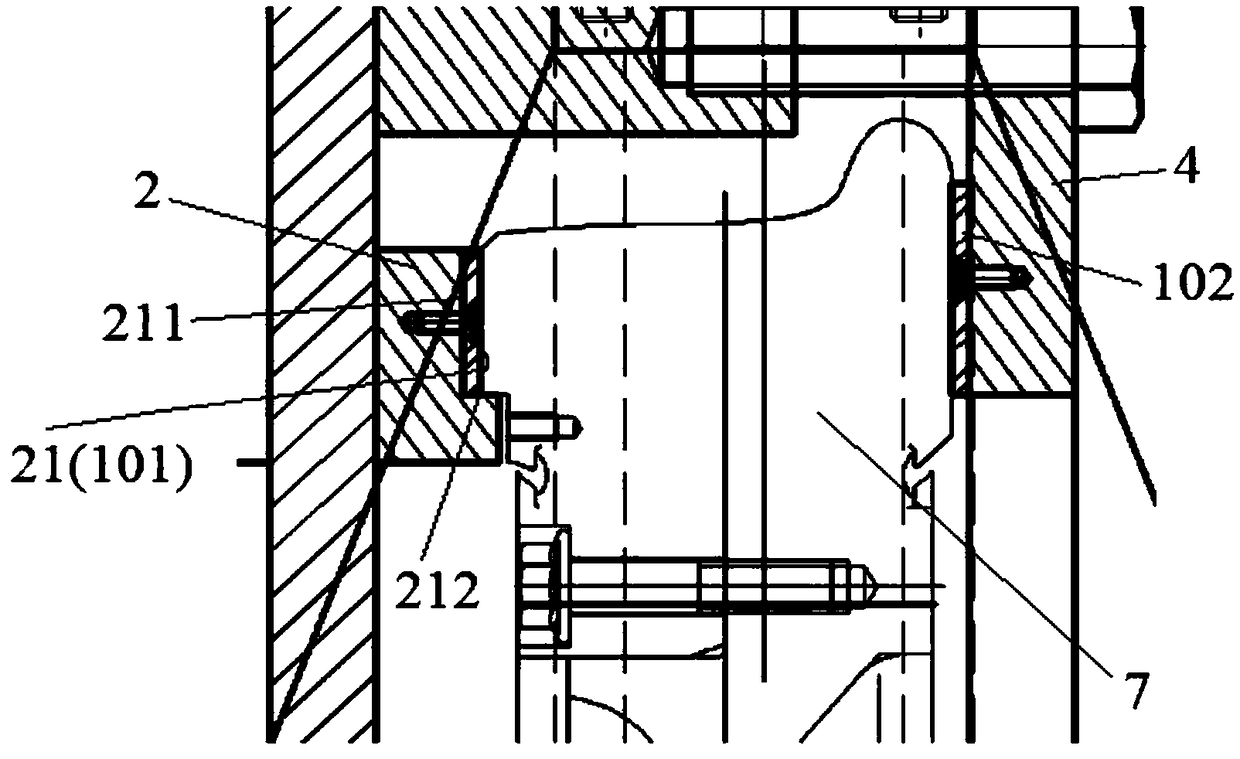

[0027] see Figure 1 to Figure 4 A kind of elastic wheel torsion test tool, including installation panel 1, positioning ring 2, fixed block 3, tire pressure plate 4, test shaft 5 and loading arm 6, installation panel 1 is fixed on the test bench and the plate of installation panel 1 The surface is set along the vertical direction, the positioning ring 2 is fixed on the mounting panel 1 and the ring surface of the positioning ring 2 is set along the vertical direction, and the positioning ring 2 is provided with a ring for positioning the tire of the wheel 7 to be tested from the radial direction. L-shaped notch 21, the radial periphery of the positioning ring 2 is centrally symmetrically distributed with eight fixed blocks 3 fixed on the installation panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com