Method for determining biological density of expanded sludge by low density microsphere method

A technology of biological density and bulking sludge, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Loose mud structure and other problems, to achieve the effect of preventing sludge stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Determine the basic parameters of expanded sludge: the average mixed liquid suspended solids concentration (MLSS) is 2800mg / L, and the average sludge volume index (SVI) value is 320mL / g;

[0020] 2. Take 3.5L of the sludge sample from the reactor where sludge expansion has occurred. After centrifugal solid-liquid separation, wash it three times with the filtered reactor effluent, then dilute it to 3.5L and place it in 7 1L on average. Among the Erlenmeyer flasks, No. 1-7 Erlenmeyer flasks.

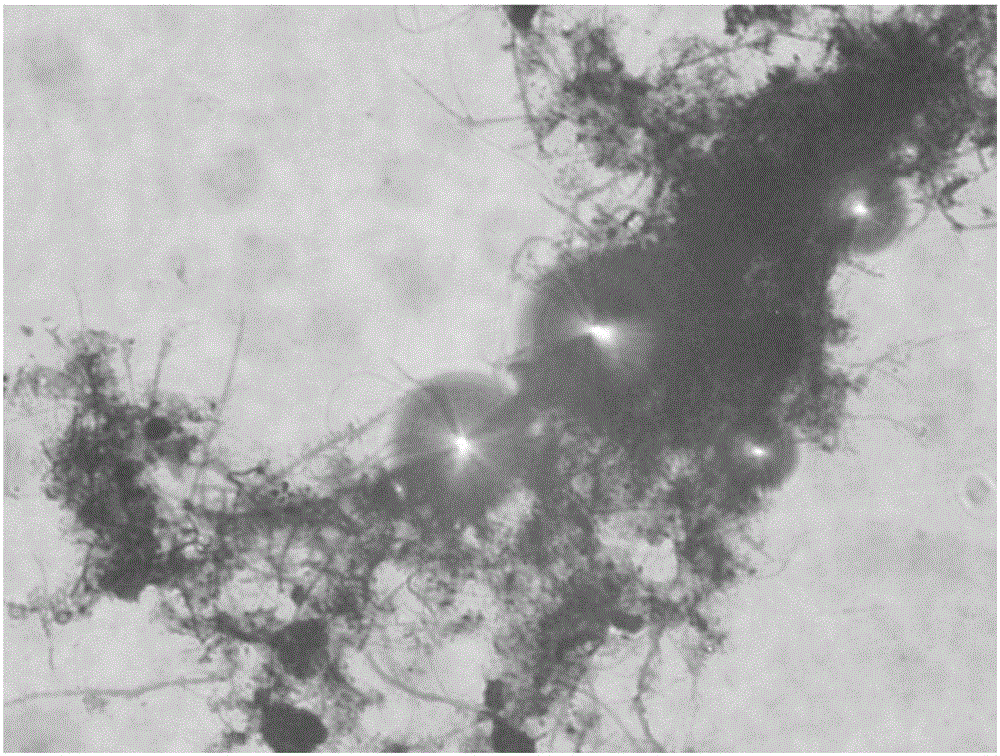

[0021] 3. Add 0.04g, 0.08g, 0.12g, 0.16g, 0.2g, 0.24g, 0.28g iM16K glass microspheres (3M company, density 0.46g / mL) into 7 conical flasks, and stir with magnetic force. The device was stirred at room temperature for 10 minutes at 200 rpm until the mud sample and the microspheres were evenly mixed, and the combination of microspheres and sludge ( figure 1 ), it is found that the combination is very tight and the next step of the test operation can be carried out.

[0022] 4. Prepare DM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com