Detection method and special detection system for silica precipitation performance of nuclear power plant water filter element

A silica and water filter technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of simulated performance detection of water filter elements, low detection accuracy, and actual system pollution, etc., to achieve true and reliable data , high verification efficiency and high simulation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

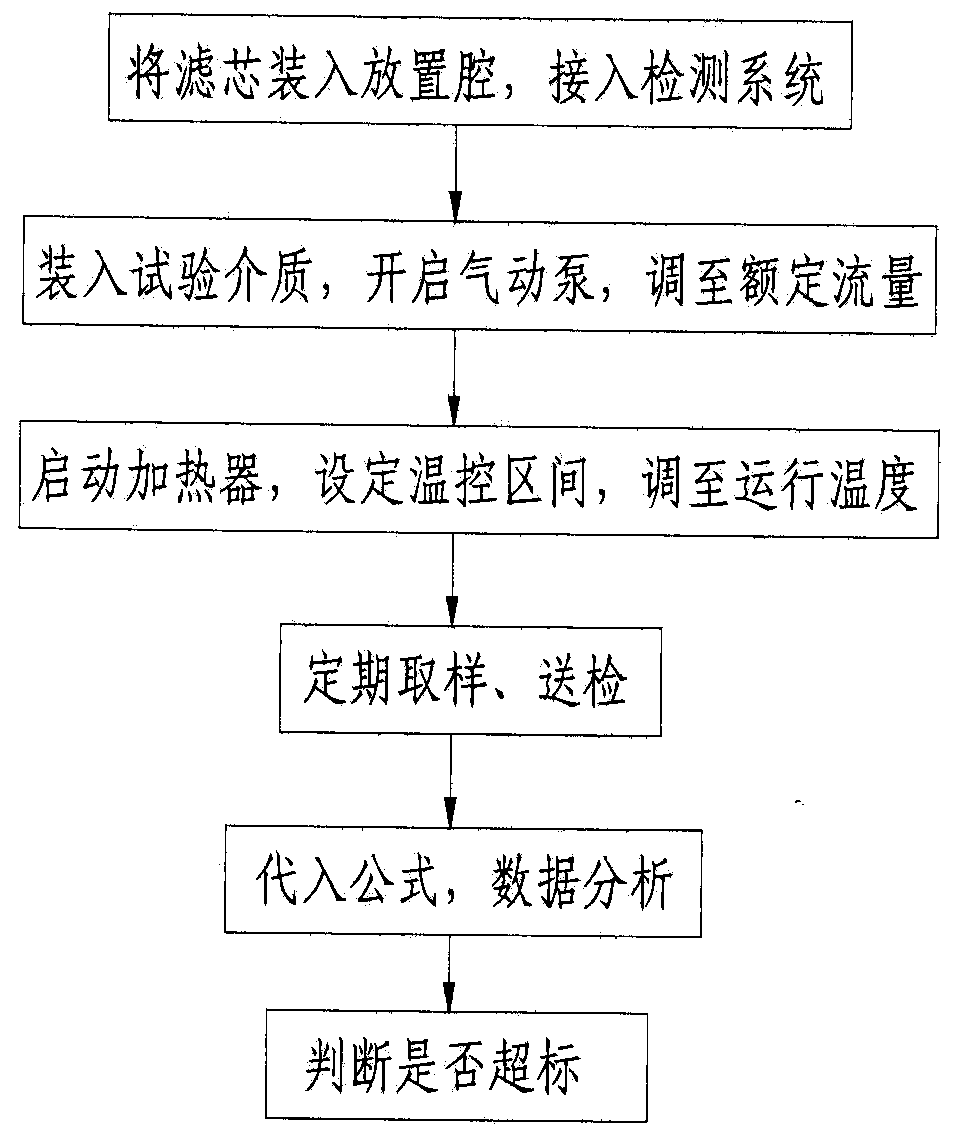

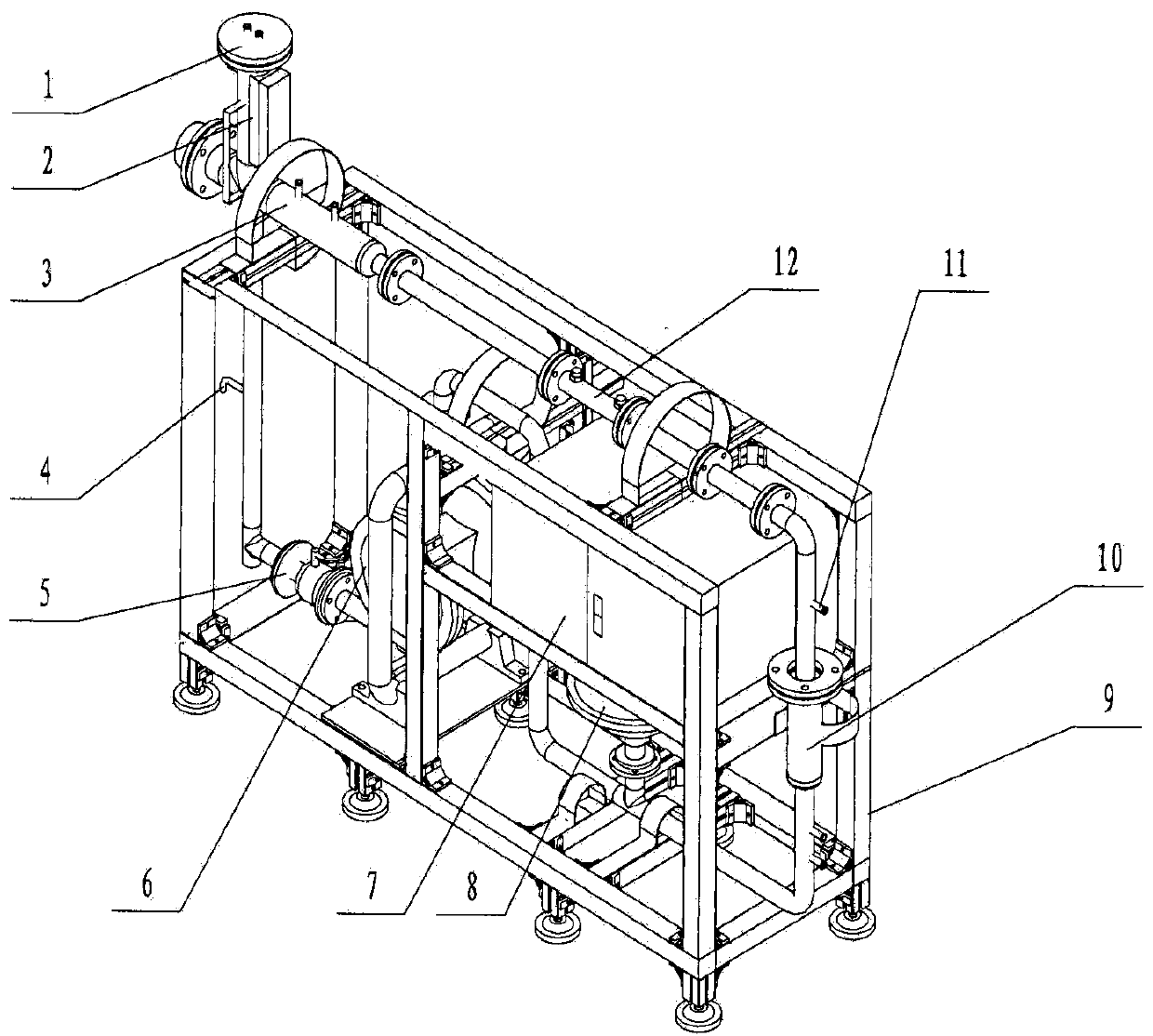

[0034] A method for detecting the silica precipitation performance of a nuclear power plant water filter element, comprising the following steps:

[0035] (1) Put the tested filter element (10 inches—5 μm) into the system, add a mixed solution of boric acid with a concentration of 200ppm and LiOH with a concentration of 1.24±10%ppm, so that the height of the solution reaches the upper and lower marks of the liquid level indicator;

[0036] (2) Turn on the pneumatic pump and adjust the flow regulating valve to reach the rated flow rate of the filter element of 4.2m 3 / h;

[0037] (3) Take the initial water sample from the sampling port, to be submitted for inspection and obtain the original concentration of silica in the liquid;

[0038] (4) Turn on the electric heater to gradually increase the temperature to the working temperature of 72±2°C and keep it within this temperature range;

[0039] (5) Sampling on time, the sampling frequency is 1-3 days, 1 time / 24 hours; after th...

Embodiment 2

[0041] The method for detecting the silica precipitation performance of the nuclear power plant water filter element comprises the following steps:

[0042] (1) Put the tested filter element (10 inches—25 μm) into the system, add a mixed solution of boric acid with a concentration of 200ppm and LiOH with a concentration of 1.24±10%ppm, so that the height of the solution reaches the upper and lower marks of the liquid level indicator;

[0043] (2) Turn on the pneumatic pump and adjust the flow regulating valve to reach the rated flow rate of the filter element of 8.4m 3 / h;

[0044] (3) Take the initial water sample from the sampling port, to be submitted for inspection and obtain the original concentration of silica in the liquid;

[0045] (4) Turn on the electric heater to gradually increase the temperature to the working temperature of 72±2°C and keep it within this temperature range;

[0046] (5) Sampling on time, the sampling frequency is 1-3 days, 1 time / 24 hours; after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com