Heating working condition thermal performance calculation method of extraction steam heating unit

A technology of thermal performance and working conditions, which is applied in the field of thermal performance calculation of steam extraction heating unit heating conditions, can solve the problems of large workload of thermal test method, and does not consider the influence of steam and water loss on the thermal performance of units in the whole plant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below:

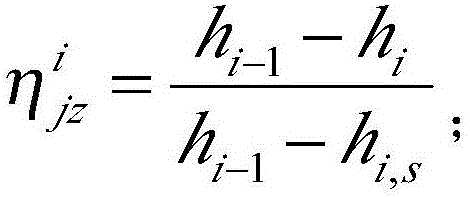

[0044] A method for calculating the thermal performance of a steam extraction heating unit under heating conditions, comprising the following steps:

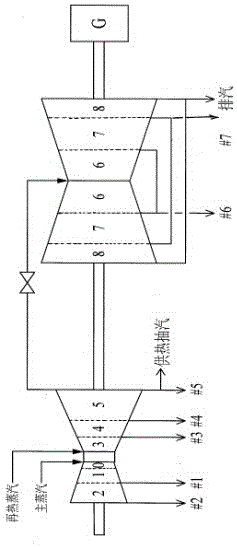

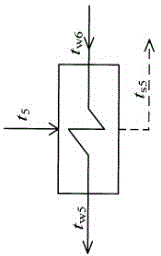

[0045] The first step is to define the adjustment stage of the high-pressure cylinder of the steam extraction heating turbine unit as the 0th stage group, and define the pressure stage group between the adjustment stage and the first steam extraction port (#1) of the high-pressure cylinder along the steam flow direction as the 0th stage group 1 pressure level group, the pressure level group between the first extraction port (#1) of the high pressure cylinder and the exhaust port (#2) of the high pressure cylinder is defined as the second pressure level group; along the steam flow direction, the steam enters from the medium pressure cylinder The pressure stage group between the port and the first extraction port (#3) of the intermediate pressure cylinder is defined as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com