A small liquid cooling system and method driven by an electro-hydraulic power micropump

An electro-hydraulic power, micro-pump technology, applied in circuits, electrical components, electro-solid devices, etc., can solve the problems of inaccurate flow control, large size, and high power consumption, and achieve maintenance-free, small size, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

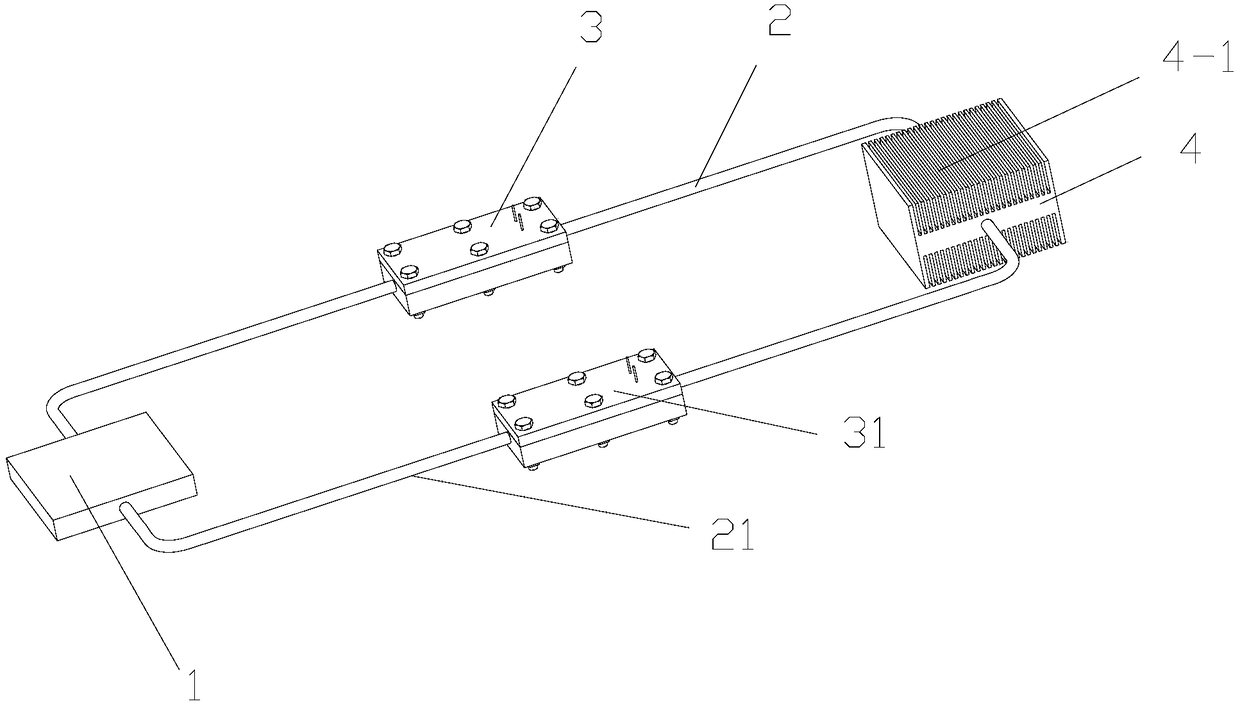

[0029] Such as Figures 1 to 3 shown. The invention discloses a small-sized liquid cooling system driven by an electro-hydraulic power micropump, comprising a liquid cooling block 1 filled with a liquid working medium and a heat exchanger 4 filled with a liquid working medium; the outlet of the heat exchanger 4 passes through The first loop pipeline 2 is connected to the inlet of the liquid cooling block 1, and the first electro-hydraulic power micropump 3 is connected in series on the pipeline of the first loop pipeline 2; the outlet of the liquid cooling block 1 passes through the second loop pipeline 21 The inlet of the heat exchanger 4 is connected, and a second electro-hydraulic power micropump 31 is connected in series on the pipeline of the second loop pipeline 21 .

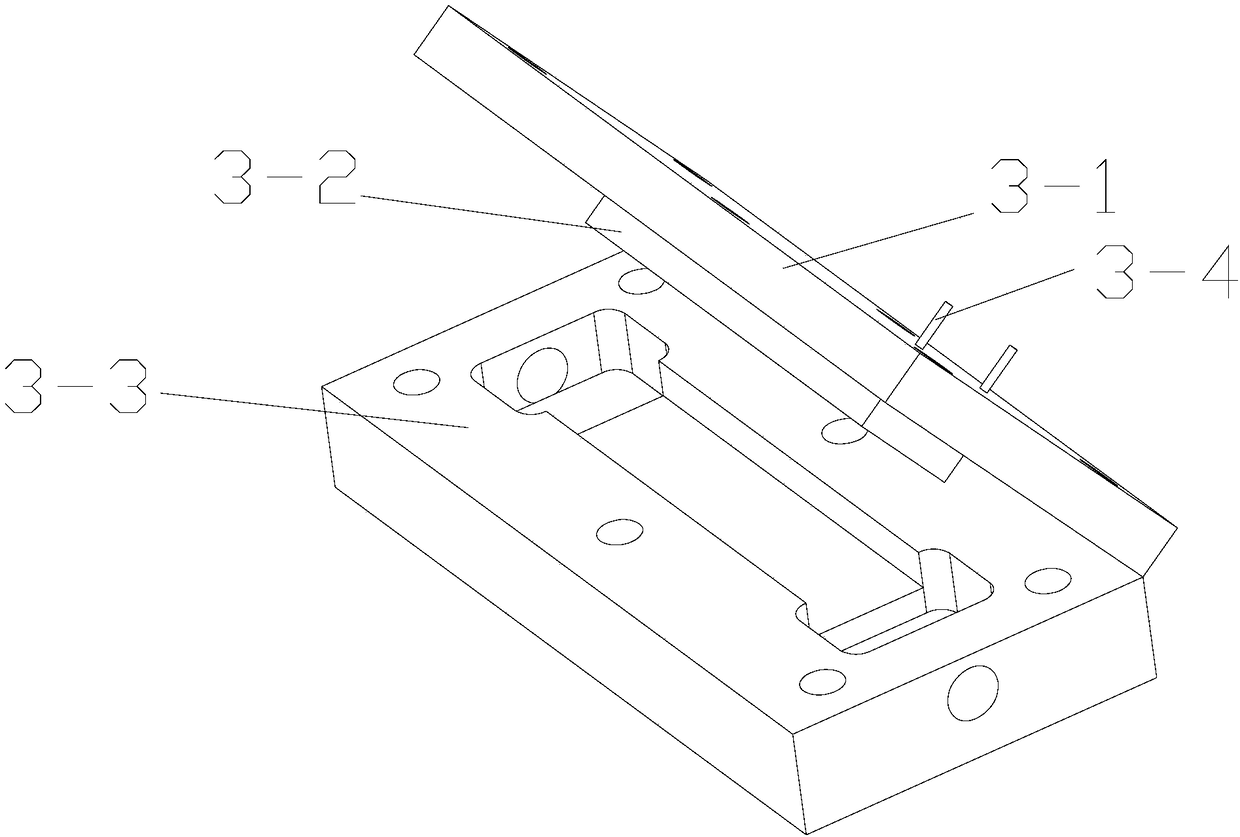

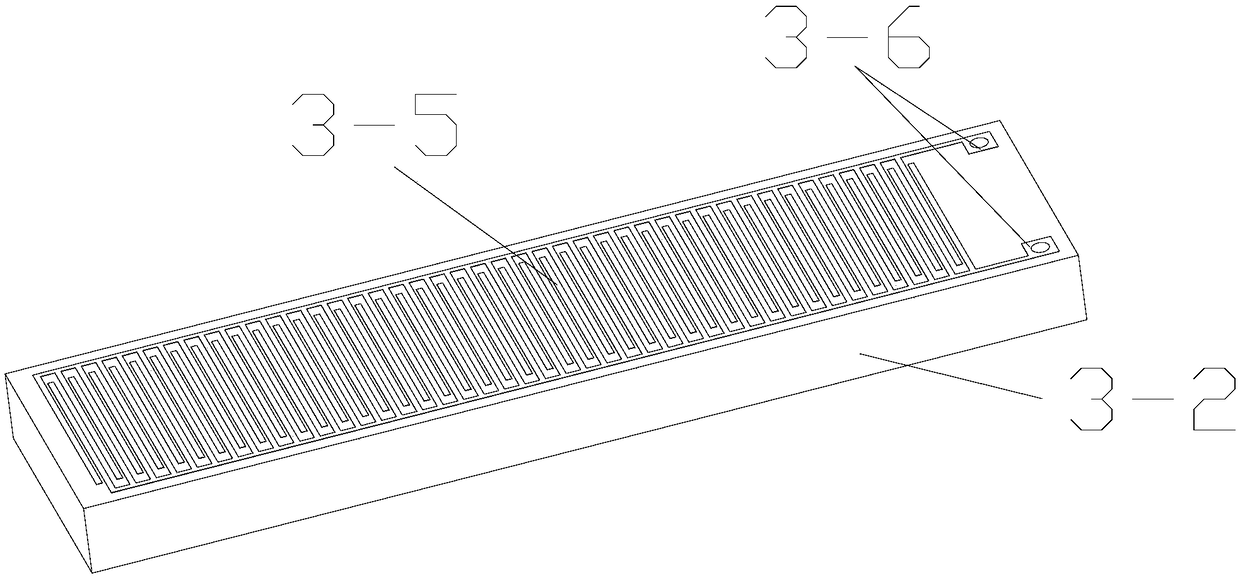

[0030] The first electro-hydraulic power micropump 3 includes a cavity 3-3, a sealing end cover 3-1 matched with the cavity 3-3, arranged on the inner surface of the sealing end cover 3-1 and extending to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com