A high-voltage distributed laser energy supply unit

A laser energy supply and distributed technology, applied in the direction of electrical components, photovoltaic modules, photovoltaic power stations, etc., can solve rare problems, achieve the effects of avoiding losses, improving product reliability, and maximizing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

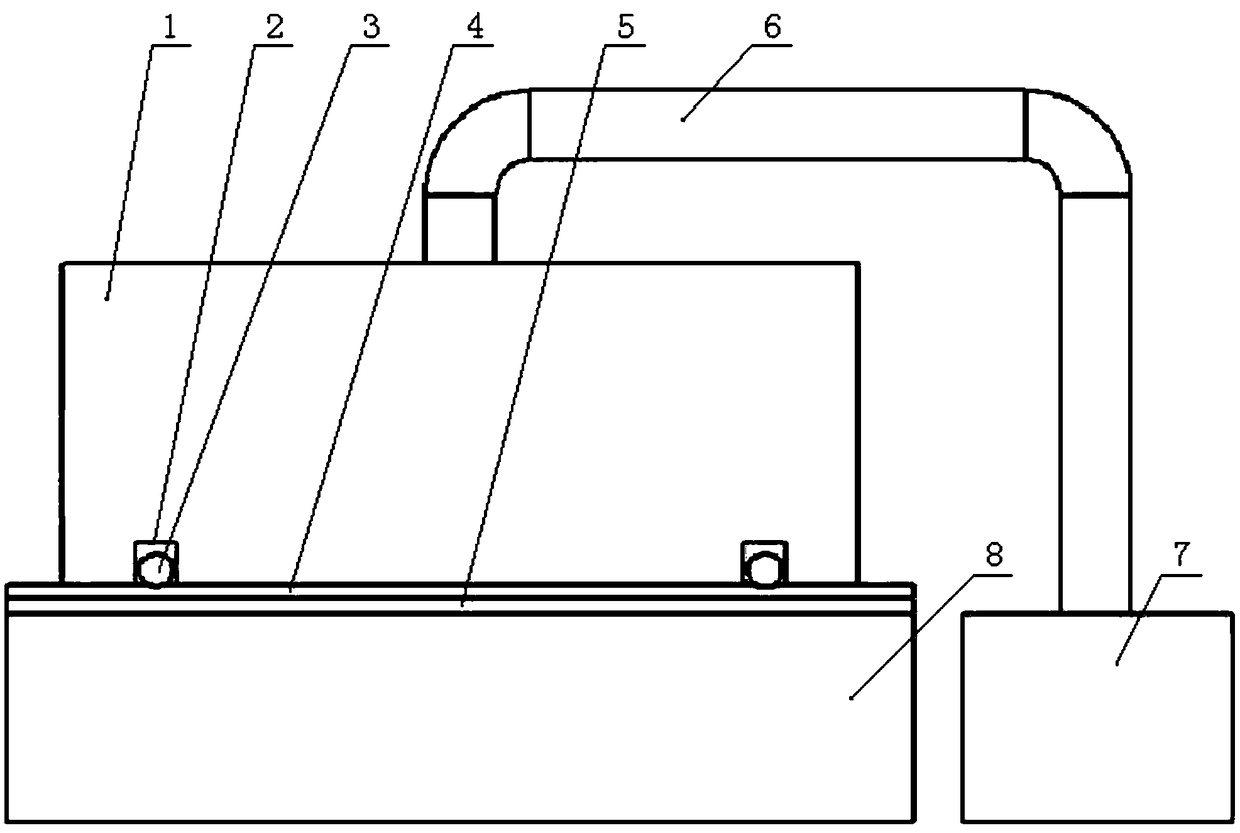

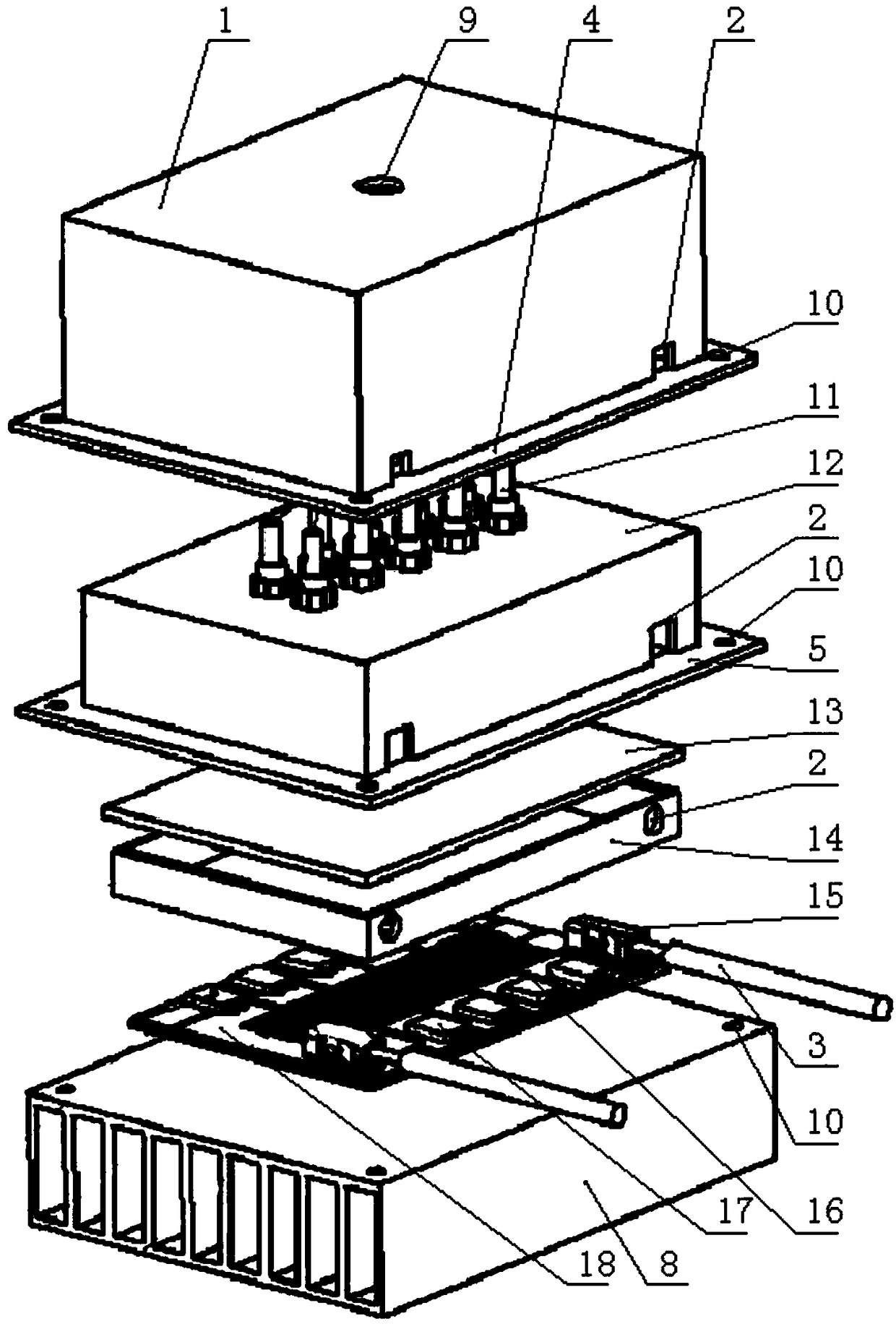

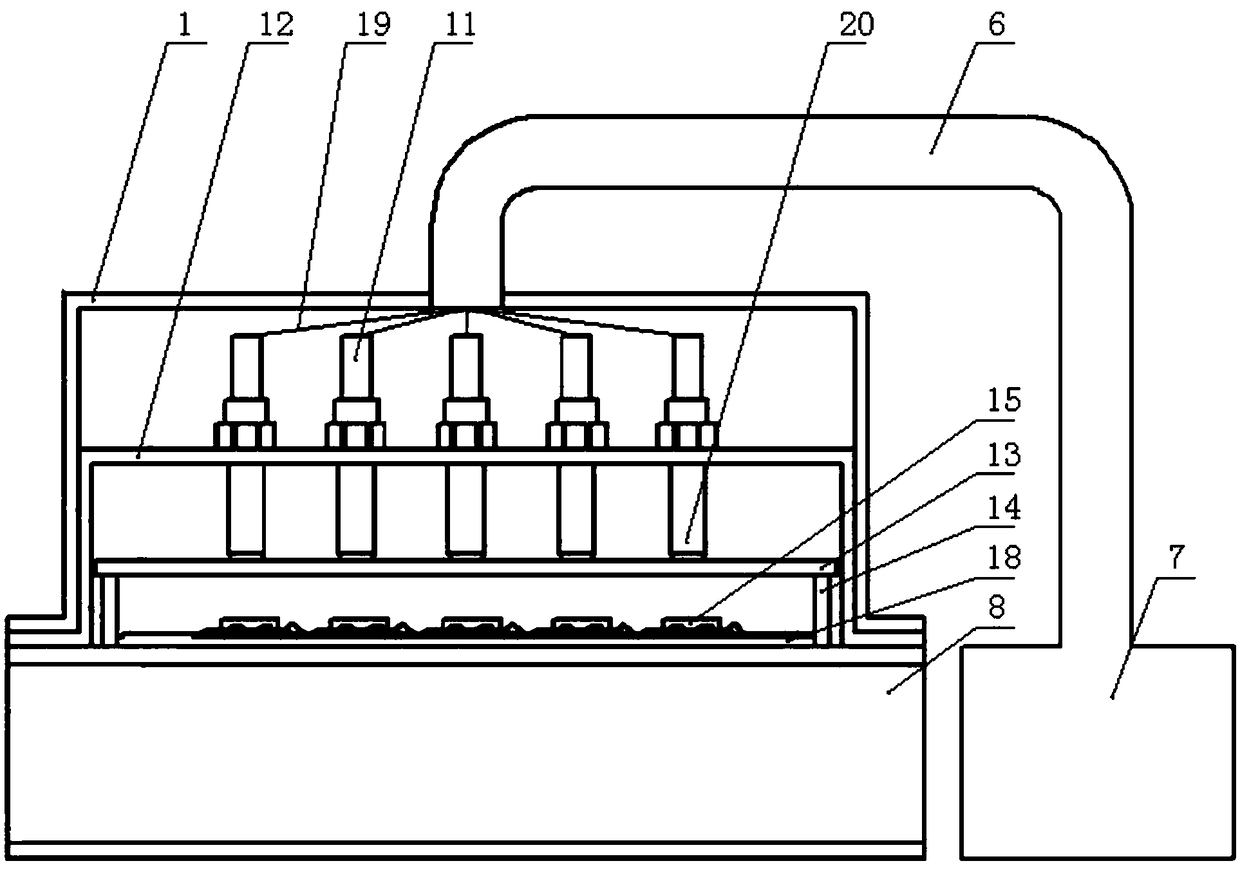

[0017] A high-voltage distributed laser energy supply unit, such as Figure 1~4 Shown, comprise laser 7, glass sheet 13, substrate 18, photovoltaic cell 16 and radiator 8, substrate is installed on the radiator, glass sheet is arranged above the substrate, the laser that laser is exported by optical fiber is positioned at the top of glass sheet, innovation of the present invention is: The photocells are multiple and installed on the substrate, the plurality of photocells are connected in series and connected to two wires 3 respectively through two connectors 15 installed on the substrate, and the optical fiber covering the substrate is installed on the radiator Splice box 12, a protective cover 1 is installed on the optical fiber splice b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com