Rotary-table bearing assembly

A technology for turntable bearings and outer rings, applied to bearings, rotating bearings, roller bearings, etc., can solve problems such as life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

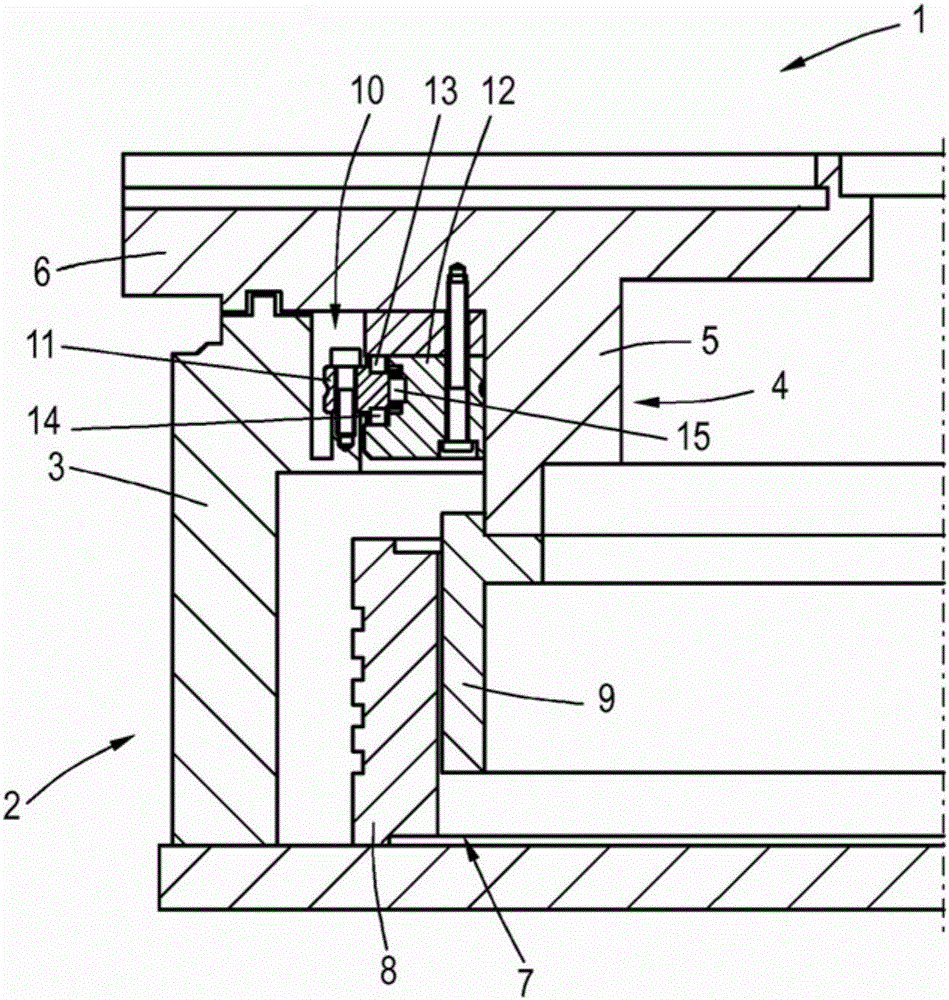

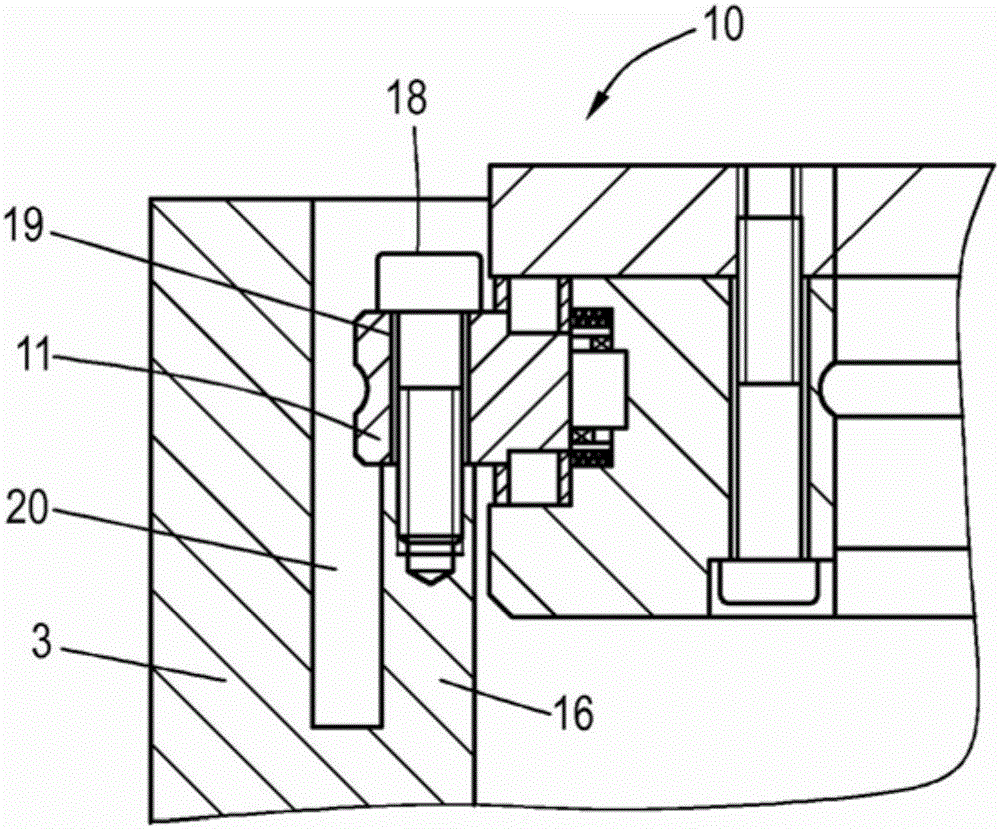

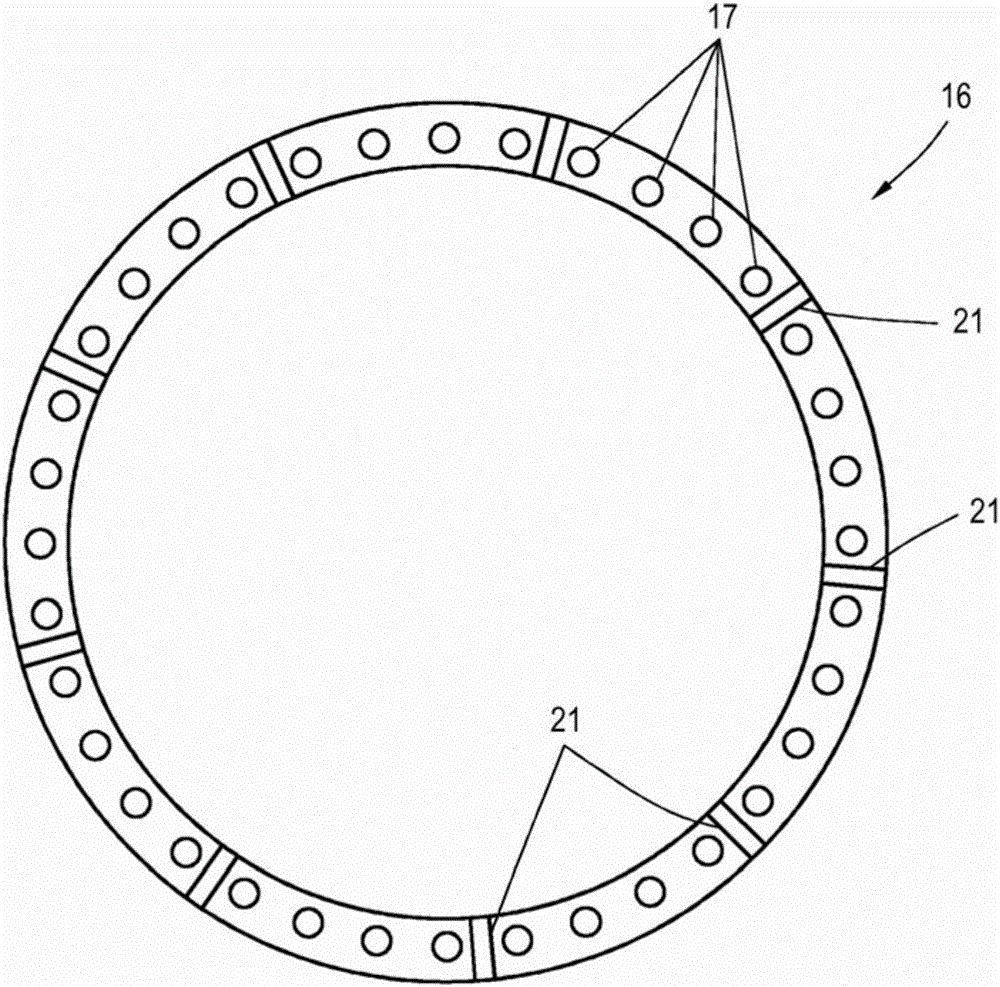

[0023] figure 1 Shown is a part of a turntable machine 1 according to the invention, which comprises a stand 2 with a support member 3 which is a fitting member with an outer bearing for the turntable bearing. The clamping section of the ring, which is described below.

[0024] Furthermore, a shaft 4 is provided, which has a further mounting component with a clamping section for the inner ring of the turntable bearing, wherein the clamping section is via the hollow cylindrical shape of the shaft 4 Section 5 of is implemented. The shaft 4 has a platform flange 6 , on which, in a manner not shown, its own turntable is accommodated.

[0025] A torque motor 7 is provided for driving the shaft 4, said torque motor comprising: a stator 8, fixed on the frame side; and a rotor 9, separated via an air gap, arranged in a hollow cylindrical section of the shaft 4 In the extension of 5. The stator 8 and the rotor 9 are separated in a known manner via an air gap, so that the rotor 9 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com