Flow sensor for pulmonary function testing

A flow sensor and lung function technology, applied in the field of medical devices, can solve the problems of mutual conversion, affecting test accuracy, blocking mesh, etc., and achieve the effect of low cost, high detection sensitivity and accurate value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

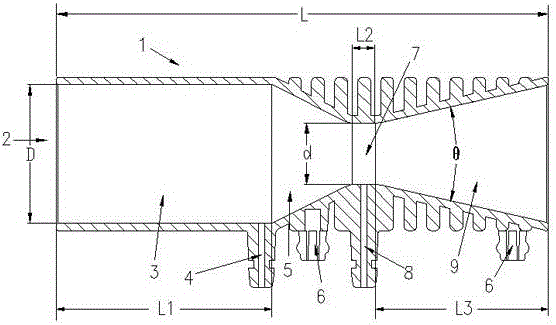

[0013] Embodiment: a flow sensor for pulmonary function detection, together with the host of the pulmonary function instrument to form a pulmonary function instrument, such as figure 1 As shown, it includes a base body 1. The total length L of the base body 1 is 100 mm. The base body 1 is provided with a through-hole 2 that can be blown, a high-pressure pressure tapping port 4, and a low-pressure pressure tapping port 8. The through-hole 2 is blown from the air. One end to the other end where the air blows out is provided with an inlet section 3, a contraction section 5, a throat section 7, and a diffusion section 9 in sequence. The diameter D of the inlet section 3 is 25mm, the length L1 of the inlet section 3 is 45mm, and the throat section 7 The diameter d is 12mm, the length L2 of the throat section 7 is 10mm, the constriction section 5 is in the shape of a circular platform, the large end of the constriction section 5 is connected with the inlet section 3, the small end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com