A kind of preparation method of hydrophilic organosilicon film

A silicone and hydrophilic technology, applied in the field of preparation of hydrophilic silicone membrane, can solve the problems of poor water affinity and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

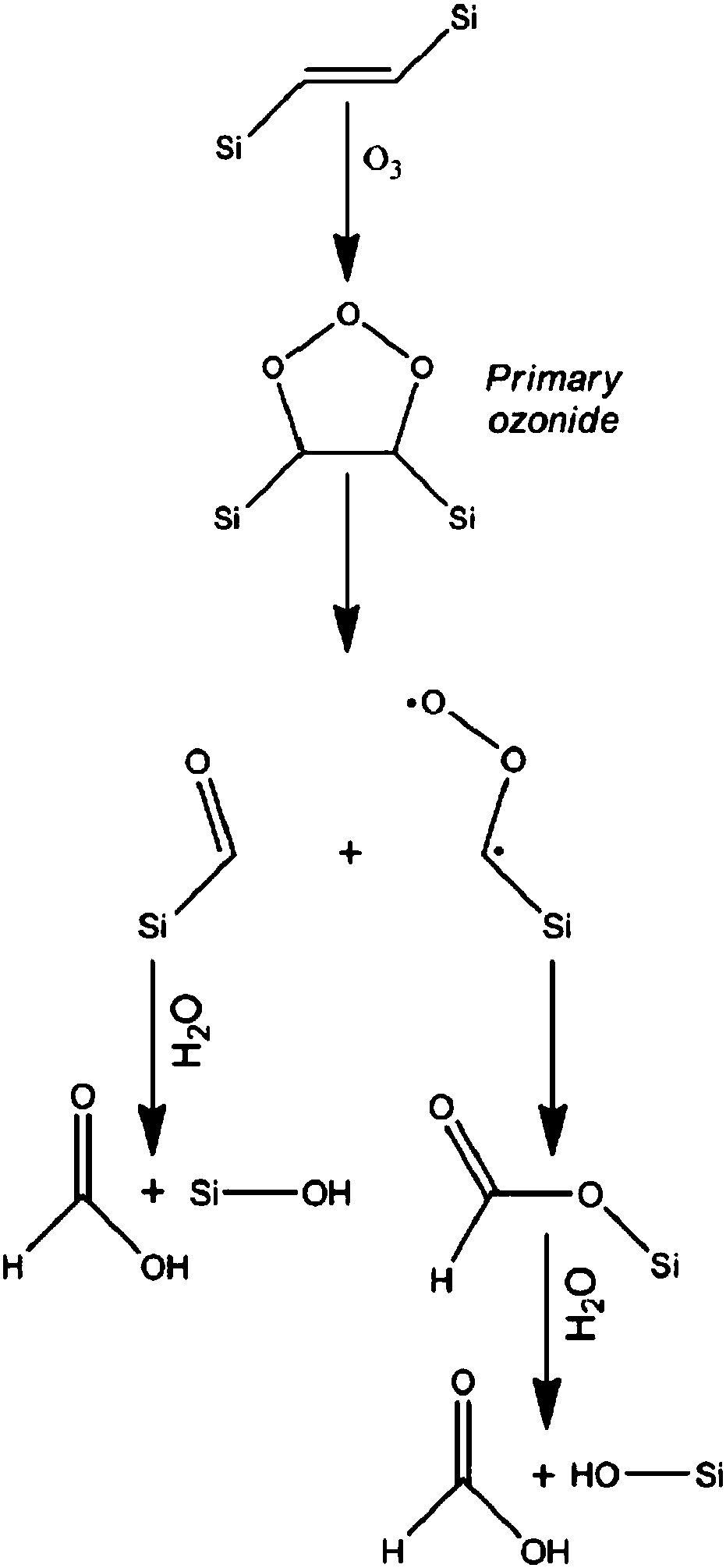

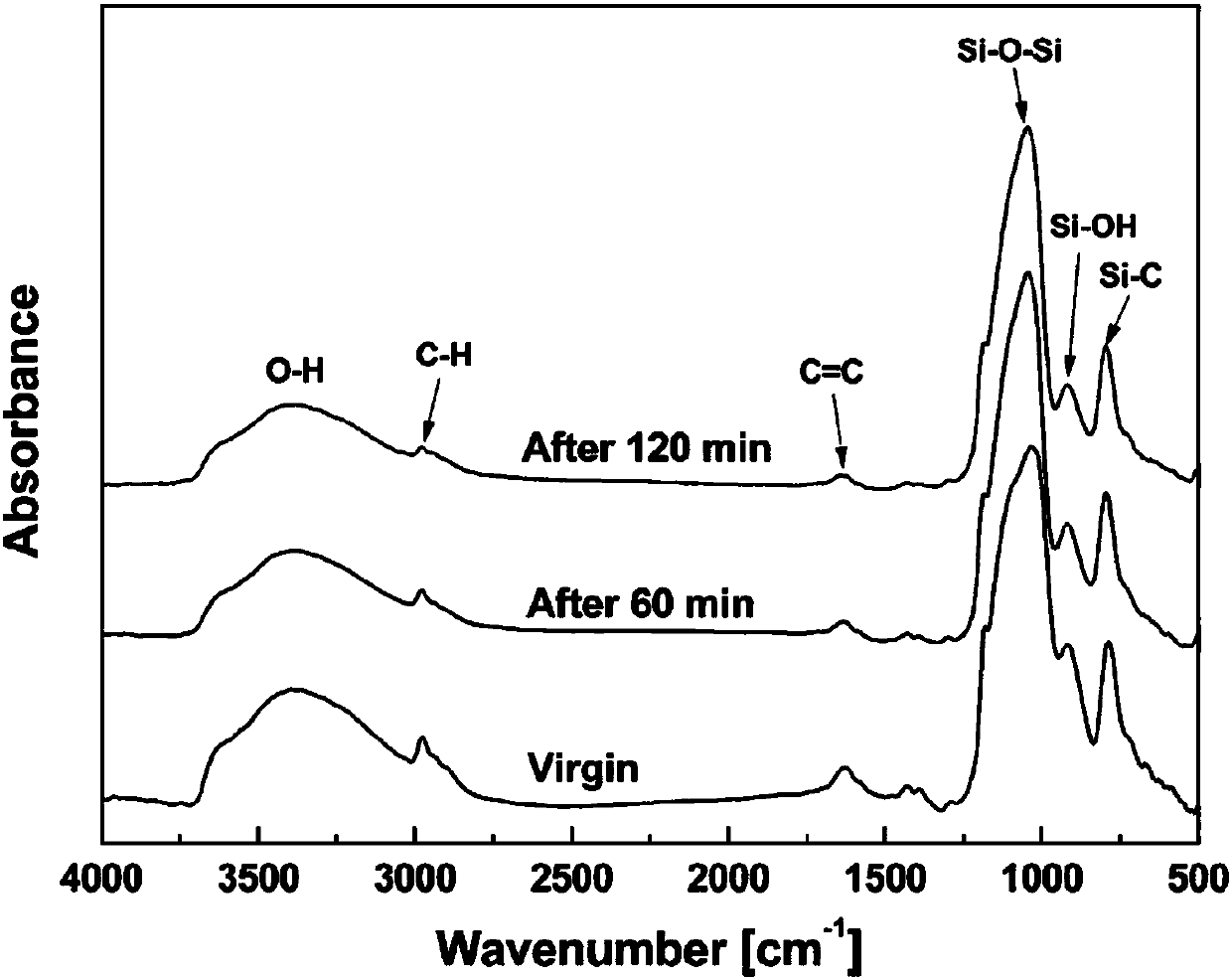

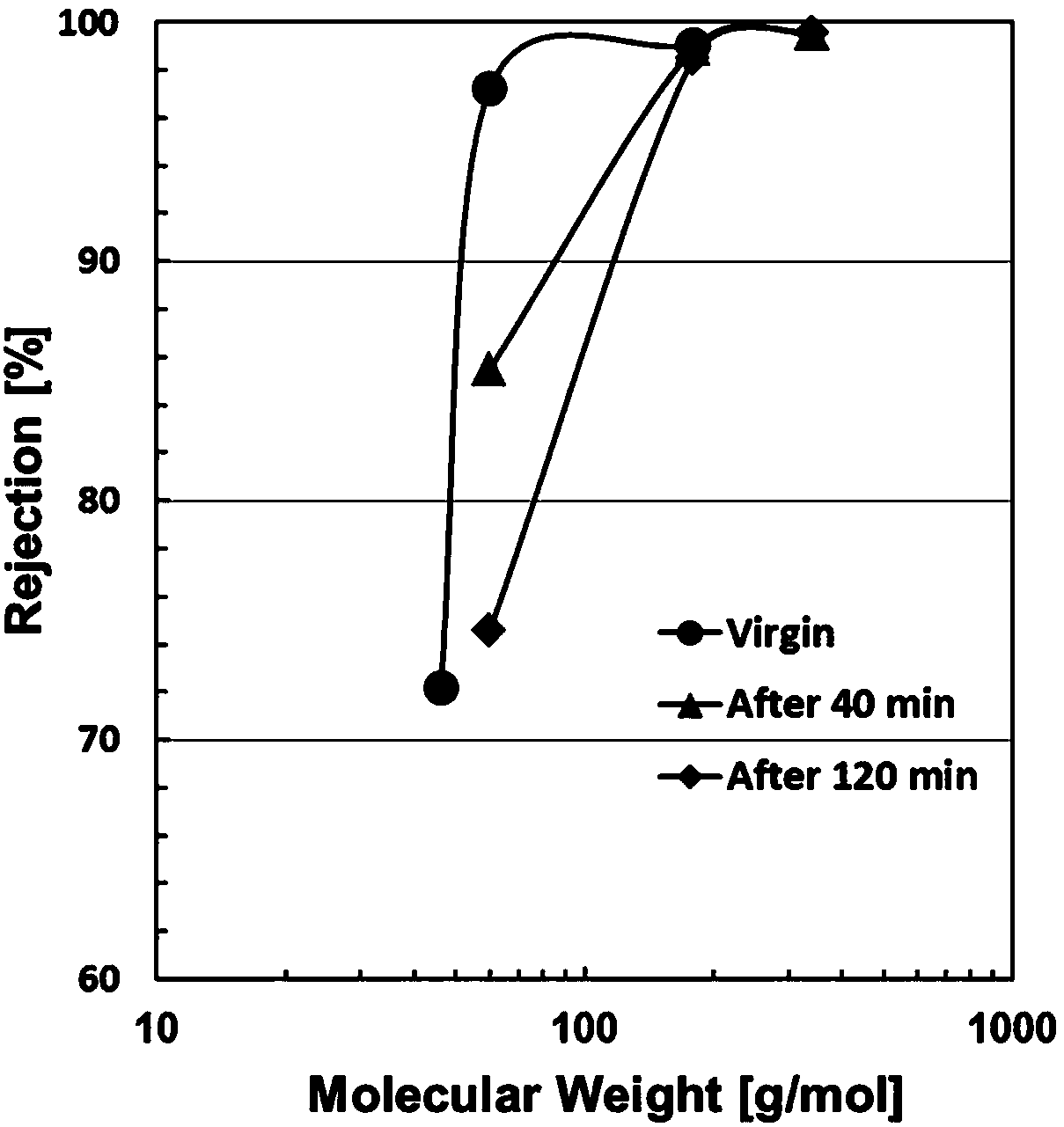

Method used

Image

Examples

Embodiment 1

[0026] (1) Under the catalysis of hydrochloric acid, the organosilicon polymer sol was prepared by the hydrolysis polymerization reaction of the organosilicon source precursor BTESEthy, and the concentration of the sol was diluted to 0.4wt%;

[0027] (2) Adopt hot-coating method to wiping-coat silicon-zirconium sol (0.3wt%) on the ceramic support body, calcine 25min under the high temperature condition of 500 ℃ to form a film, repeat the operation of wiping sol and calcining 8 times, obtain the film transition layer;

[0028] (3) Wipe-coat the organosilicon polymer sol obtained in step (1) on the transition layer obtained in step (2) by thermal coating, and calcined at 200°C for 20 minutes after coating, and repeat the wiping-coating sol and calcining The operation is performed twice to obtain the organic silicon film,

[0029] Prepare 7 parts of the same above-mentioned organosilicon film;

[0030] (4) Soak 6 parts of organosilicon membranes prepared in step (3) in aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com