Energy-saving peeling air knife based on wall attachment effect for planar-flow melt spinning

A technology of wall attachment effect and planar flow, which is applied in the field of energy-saving stripping air knife for planar flow casting, can solve the problems that the adjustment device cannot be adjusted, increases the difficulty of the process, affects the production efficiency, etc., and achieves low consumption, good stripping effect, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

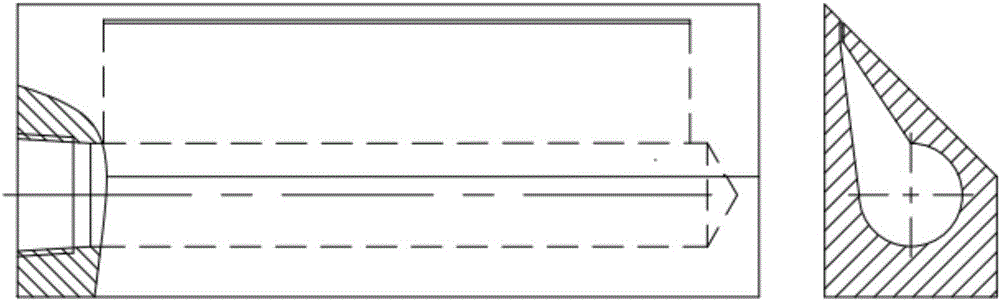

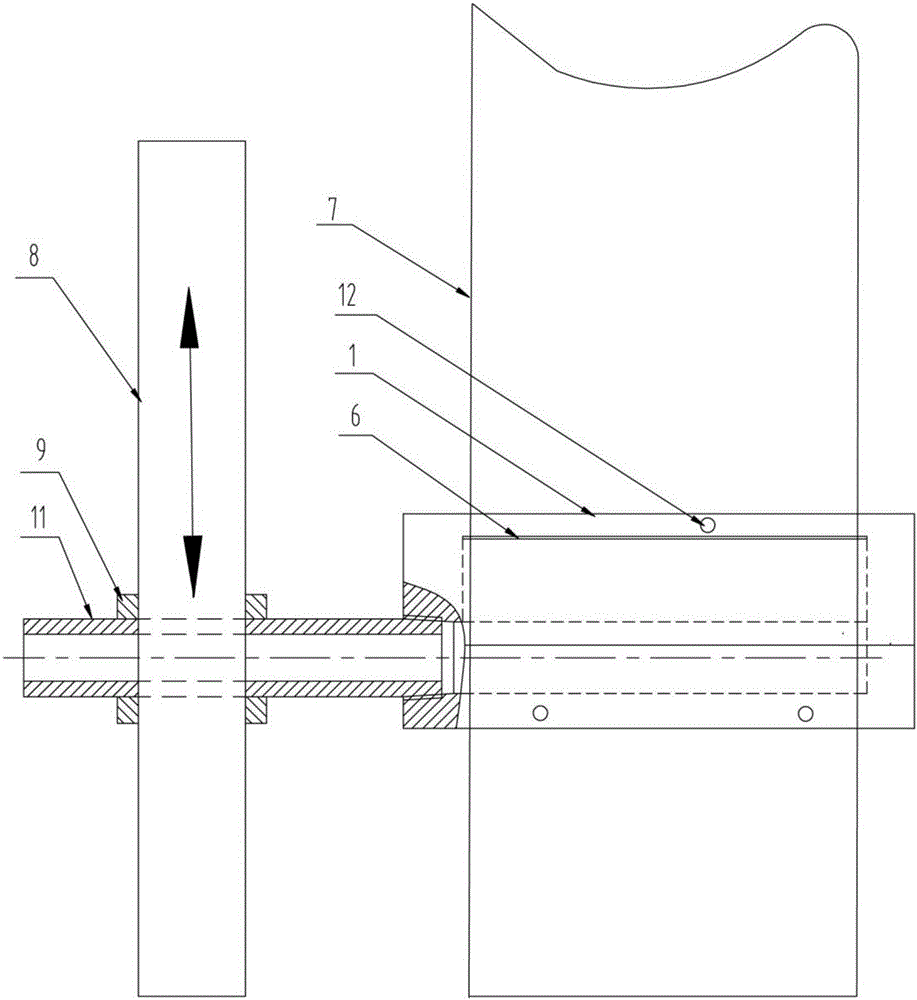

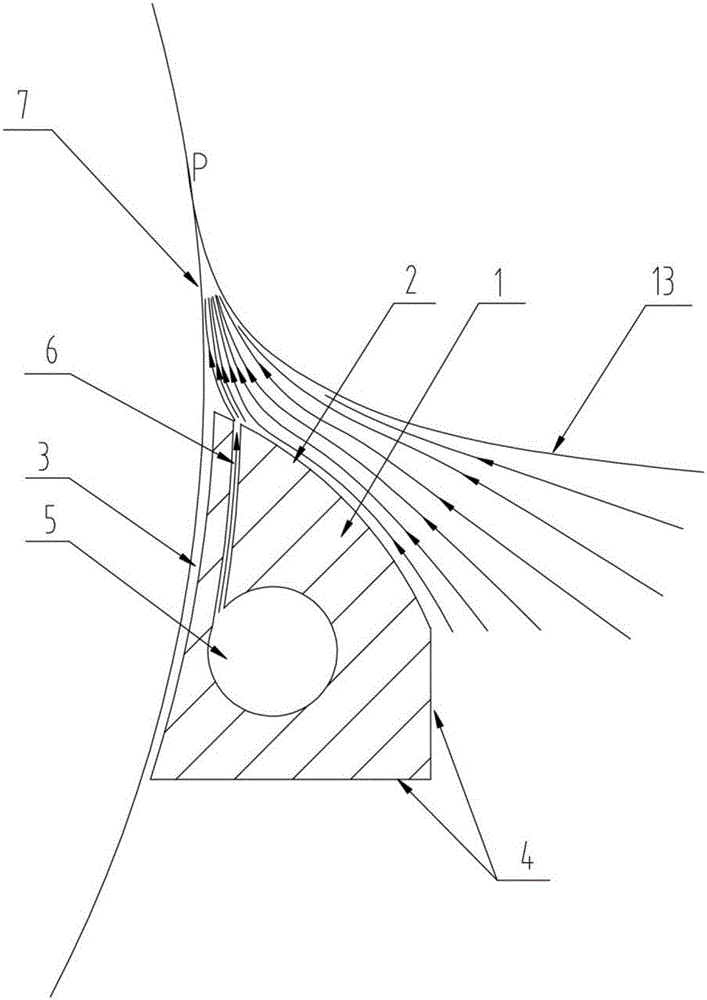

[0039] An energy-saving stripping air knife for planar flow casting based on the Coanda effect, including a support guide system and a stripping air knife body 1, the support guide system includes a support column and a dovetail base, the support column is located on one side of the cooling roll, Placed in the dovetail base; the special feature is that the support and guide system also includes a guide plate 8 and a cross beam 11; the outer wall of the peeling air knife body is composed of an outer convex arc surface 2 and an inner concave arc surface 3 Surrounded by two flat surfaces 4; the inside of the peeling air knife body includes an air chamber 5 and a spray slot 6 communicated with the air chamber;

[0040]The curvature of the concave arc surface is the same as the curvature of the outer circle 7 of the cooling roller, which is 1 / R; the inner concave arc surface is inscribed with the outer circle of the cooling roller; the curvature of the outer convex arc surface is 1 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com