Preparation method of nano-anion PVC (polyvinyl chloride) plate, car pendant and house decoration product

A nano negative ion and nano negative ion powder technology, applied in the field of air purification, can solve the problems of insufficient adsorption of air dust pathogenic bacteria, complex configuration, inconvenient installation and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a house decoration product, which includes a nano negative ion PVC board. The nano negative ion PVC board is prepared by the following method:

[0036] (1) the nano-anion powder is made into a nano-anion powder solution through a deployment step, and then the nano-anion powder solution is printed on 5 layers of PVC boards by silk screen printing, and a nano-anion powder layer is formed on each layer of PVC board;

[0037] (2) The 5-layer PVC board that is loaded with nano-anion powder layer is sent into lamination equipment and laminated, and is prepared into a nano-anion PVC board, wherein the thickness of each layer is 0.2-0.5mm;

[0038] (3) Send the nano-anion PVC board into the punching equipment, and punch it according to the specifications that the length is 45cm and the width is 30cm.

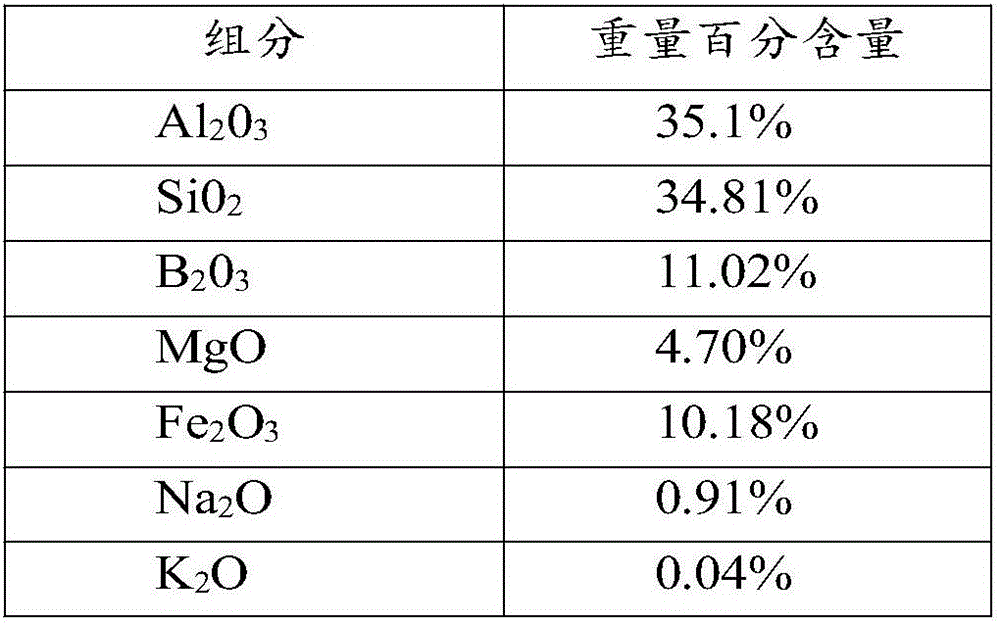

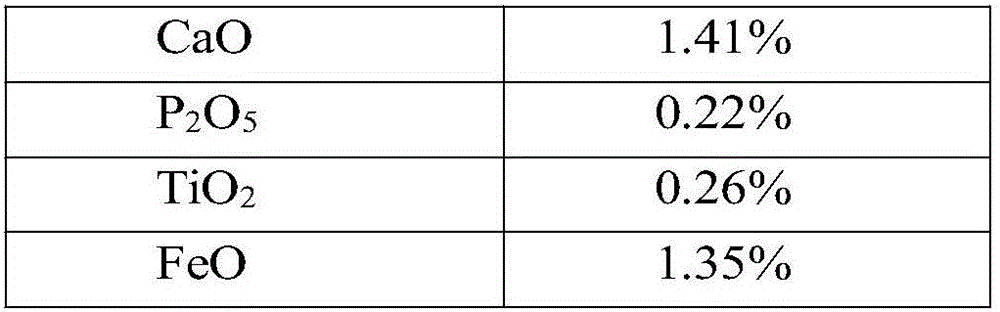

[0039] Wherein, preferably, the composition of nano-anion powder and the weight percentage of each composition are as shown in Table 1 below.

...

Embodiment 2

[0044] The present embodiment provides an automobile hanger, which includes a hanger body and a nano negative ion PVC board arranged on the hanger body. The nano negative ion PVC board is prepared by the following method:

[0045] (1) the nano-anion powder is made into a nano-anion powder solution through the steps of deployment, and then the nano-anion powder solution is printed on 7 layers of PVC boards by silk screen printing, and a nano-anion powder layer is formed on each layer of PVC board;

[0046] (2) The 7-layer PVC board that is loaded with nano-anion powder layer is sent into lamination equipment and laminated, and is prepared into a nano-anion PVC board, wherein the thickness of each layer is 0.2mm;

[0047](3) Send the nano-anion PVC board into the punching equipment, and punch it according to the specifications that the length is 55mm and the width is 55mm.

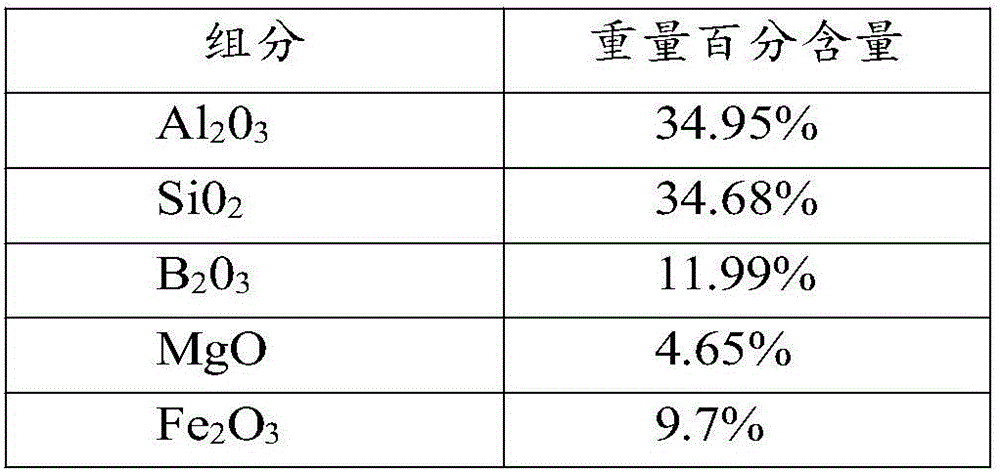

[0048] Wherein, the components of the nano-anion powder and the weight percentages of each component are...

Embodiment 3

[0054] The present embodiment provides a kind of preparation method of nano negative ion PVC board, it comprises the following steps:

[0055] (1) the nano-anion powder is made into a nano-anion powder solution through a deployment step, and then the nano-anion powder solution is printed on a multi-layer PVC board by silk screen printing, and a nano-anion powder layer is formed on each layer of PVC board;

[0056] (2) Send each layer of PVC boards loaded with nano-anion powder layers into the lamination equipment, and perform lamination under the condition of 180 ° C. The lamination time is 30 minutes, and the nano-anion PVC board is prepared; then the nano-anion PVC board Send it to punching equipment for punching operation, so that multiple through holes are formed on the nano-anion PVC board;

[0057] (3) Send the nano-anion PVC board with several through holes into the punching equipment, punch it into a size specification that meets the standard, and each board after punc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com