Intelligent control system and control method based on bubble drag reduction and M ship form combination

An intelligent control system and intelligent control technology, applied in the field of ships and ocean engineering, can solve problems such as poor resistance performance, and achieve the effects of reducing navigation costs, reducing emissions, and huge economic and environmental values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

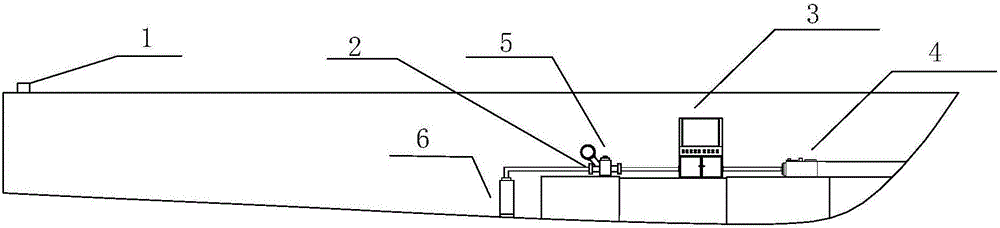

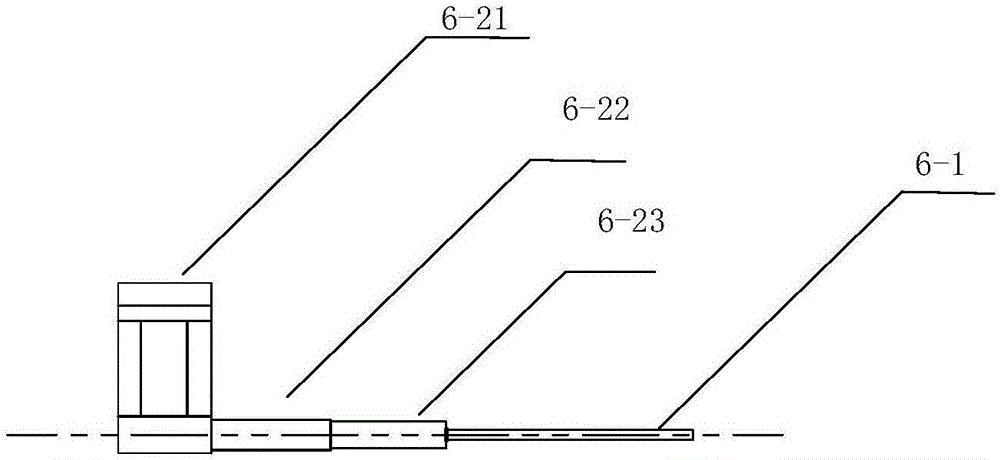

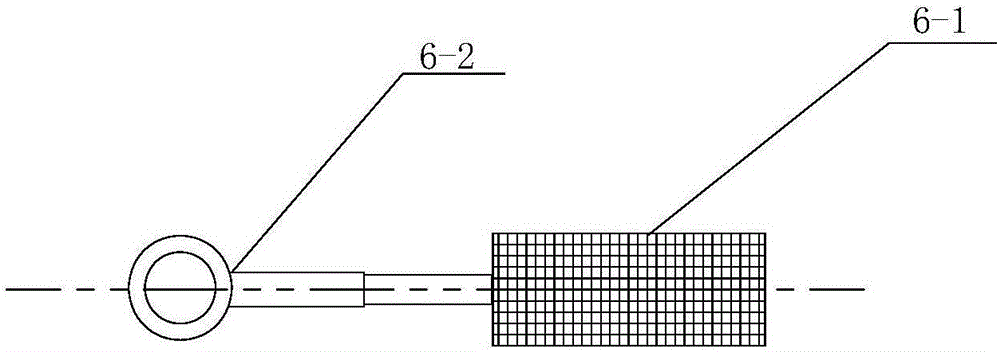

[0038] Such as Figure 1~4As shown, the present invention is an intelligent control system based on air bubble drag reduction and M ship type compound, including GPS speedometer 1, air flow meter 2, control unit 3, air compressor 4, air valve 5 and porous air bubble switching device 6.

[0039] The GPS speedometer 1 is used to collect the real-time speed of the M ship and transmit it to the control unit 3 . GPS speed measurement obtains the GPS signal through the GPS receiver installed on the moving carrier to obtain the moving speed of the moving carrier. The GPS velocimeter 1 adopted in the present invention utilizes the carrier phase real-time difference to obtain the Doppler observation value to calculate the speed of the M ship type, and the speed measurement accuracy is 0.03m / s, which meets the accuracy requirement of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com