Preparation technology of light blue low-reflection solar control film-plating glass

A solar control and coated glass technology, applied in the direction of coating, etc., can solve the problems of low visible light transmittance, high visible light transmittance, and cumbersome process steps of glass, so as to ensure visible light transmittance, reduce light pollution, and process steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

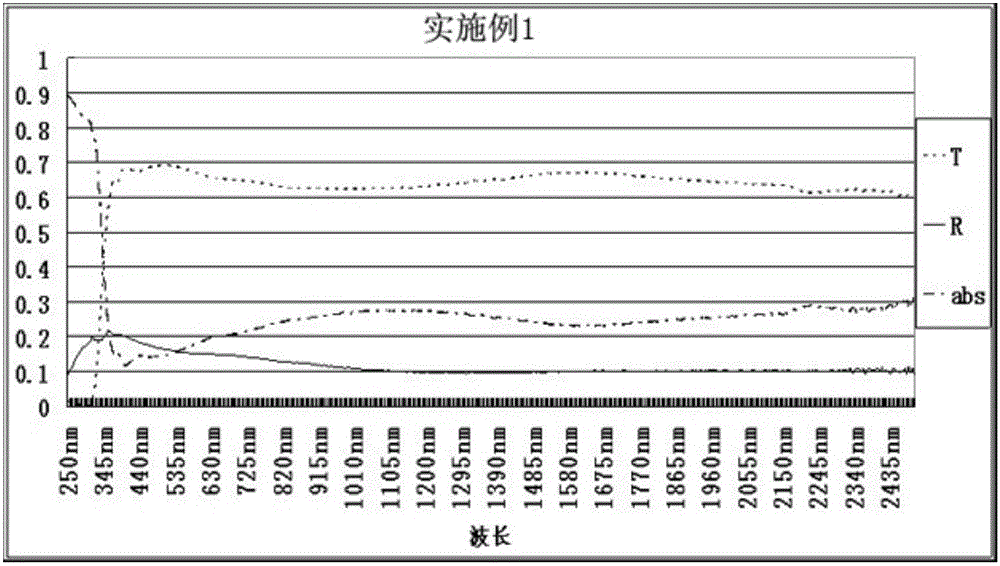

Embodiment 1

[0027] (1) First send the tin source and antimony source to the first evaporator for heating and vaporization, and the heating and gasification temperature of the first evaporator is 165°C, and then send the vaporized tin source and antimony source to the first pre-evaporator Inside and O 2 、H 2 O heating and mixing to form the first pre-mixed gas, the first pre-evaporator heating and mixing temperature is 50 ° C, and then the carrier gas is mixed with the first pre-mixed gas to form the first reaction gas and then sent to the first coating reactor, so that the second A reaction gas reacts on the surface of the glass substrate to form the first antimony-doped tin dioxide layer. The reaction temperature of the first coating reactor is 650°C, the reaction time is 1.8s, and the gas flow rate of the first reaction gas is 630L / min. The molar percentage content of each raw material in the reaction gas is: 0.135% tin source (monobutyl tin trichloride), 0.015% antimony source (antimo...

Embodiment 2

[0039] (1) First send the tin source and antimony source to the first evaporator for heating and vaporization, and the heating and gasification temperature of the first evaporator is 185°C, and then send the vaporized tin source and antimony source to the first pre-evaporator Inside and O 2 、H 2 O heating and mixing to form the first pre-mixed gas, the first pre-evaporator heating and mixing temperature is 100 ° C, and then the carrier gas is mixed with the first pre-mixed gas to form the first reaction gas and then sent to the first coating reactor, so that the second A reaction gas reacts on the surface of the glass substrate to form the first antimony-doped tin dioxide layer. The reaction temperature of the first coating reactor is 660°C, the reaction time is 4.98s, and the gas flow rate of the first reaction gas is 680L / min. The molar percentage content of each raw material in the reaction gas is: 0.234% tin source (dimethyl tin dichloride), 0.026% antimony source (antimo...

Embodiment 3

[0042] (1) First send the tin source and antimony source to the first evaporator for heating and vaporization. The heating and gasification temperature of the first evaporator is 180°C, and then send the vaporized tin source and antimony source to the first pre-evaporator Inside and O 2 、H 2 O heating and mixing to form the first pre-mixed gas, the first pre-evaporator heating and mixing temperature is 80°C, and then the carrier gas is mixed with the first pre-mixed gas to form the first reaction gas, which is sent to the first coating reactor, so that the second A reaction gas reacts on the surface of the glass substrate to form the first antimony-doped tin dioxide layer. The reaction temperature of the first coating reactor is 655°C, the reaction time is 3s, and the gas flow rate of the first reaction gas is 650L / min. Control the first The mole percentage content of each raw material in the reaction gas is: 0.24% tin source (monobutyl tin trichloride), 0.022% antimony sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com