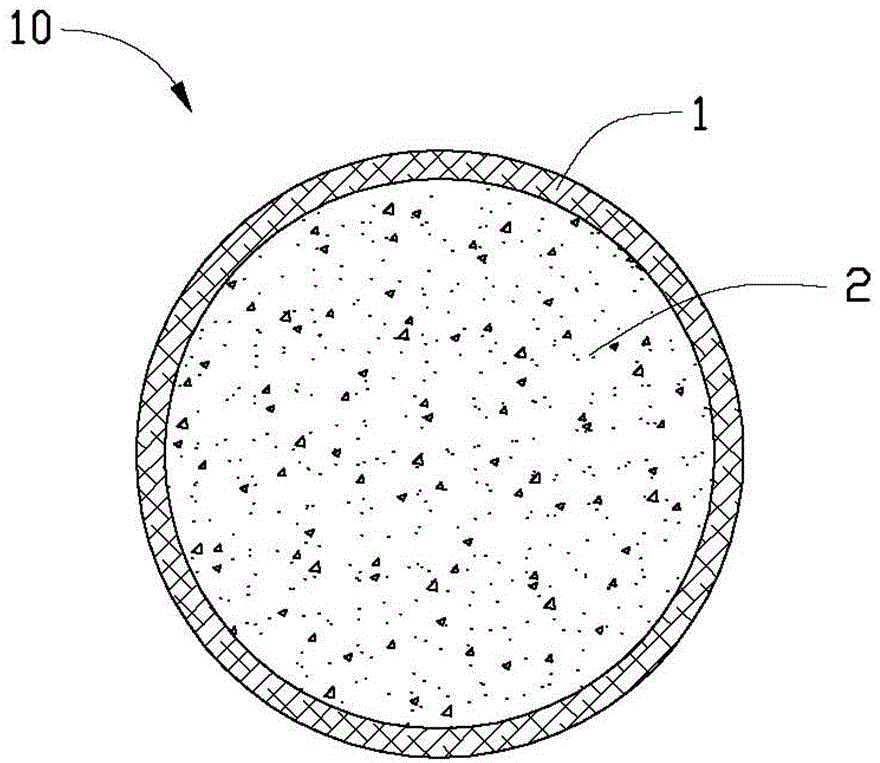

Colored microcapsule and its preparation method

A microcapsule and color technology, applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of preparing microcapsules and affecting the visual effect of products, and achieve the effect of pollution-free color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the colored microcapsules provided by the present invention is based on the composite coacervation method, using gelatin and a water-soluble polymer with an opposite charge to the gelatin as the wall material, and using a water-insoluble material as the core material, and The natural pigment is added to the microcapsule preparation system before the gelatin is cross-linked and solidified. Because there is excellent adsorption performance between gelatin and natural pigment, therefore, adopt natural pigment and gelatin system to cooperate to prepare color microcapsule in the present invention, and the addition point that natural pigment is added in microcapsule preparation system is limited to Before the gelatin is cross-linked and solidified, in this way, the natural pigment can firstly be well combined with the uncross-linked gelatin after being added, and then in the subsequent gelatin cross-linked and solidified process, the natural pigment c...

Embodiment 1

[0025] In this embodiment, the composite coacervation method is used to prepare colored microcapsules with gelatin and gum arabic as the wall materials and eucalyptus oil as the core material. The specific steps are as follows.

[0026] A gelatin solution and a gum arabic solution with a mass percent concentration of 10wt% were prepared respectively.

[0027] Weigh 51.4g of gelatin solution, 51.4g of gum arabic solution, and 75g of deionized water, mix and keep it at 40°C, then add 72g of eucalyptus oil to obtain mixed solution A.

[0028] The mixed solution A was emulsified to achieve a particle size range of about 0.5-5 microns.

[0029] Add 80-100 g of preheated deionized water to the emulsified mixed solution A for dilution, and stir for about 10 min.

[0030] Adjust the pH of the emulsion so that the pH is between 4 and 5, so that the gelatin and gum arabic are coagulated to form microcapsules, and the process is continuously stirred for about 10 minutes.

[0031] Cool ...

Embodiment 2

[0038] In this example, the composite coacervation method was used to prepare colored microcapsules with gelatin and sodium carboxymethylcellulose (CMC) as the wall materials and capsaicin as the core material. The specific steps are as follows.

[0039] A gelatin solution and a CMC solution with a mass percent concentration of 10wt% were prepared respectively.

[0040] Weigh 90g of the gelatin solution and 10g of the CMC solution and mix them, and keep them in a water bath at 40°C to fully mix the gelatin solution and the CMC solution, then add 10g of capsaicin after cooling down to room temperature to obtain a mixed solution A.

[0041] Add 890 g of preheated deionized water to the mixed solution A for dilution to obtain a diluted solution B.

[0042] Diluent B was emulsified to achieve a particle size range of about 0.5-5 microns.

[0043] Under the condition of constant temperature and stirring at 40°C, the pH of the emulsion was adjusted with 10% acetic acid solution to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com