A kind of Mn-ni-sn-co alloy thin strip and its preparation method

A technology of thin strips and alloys, applied in the field of Mn-Ni-Sn-Co alloy thin strips and its preparation, can solve the problems of limited practical application, high brittleness of bulk alloys, and difficult processing, so as to expand the magnetic difference and improve Effect of saturation magnetization and improvement of magnetocaloric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

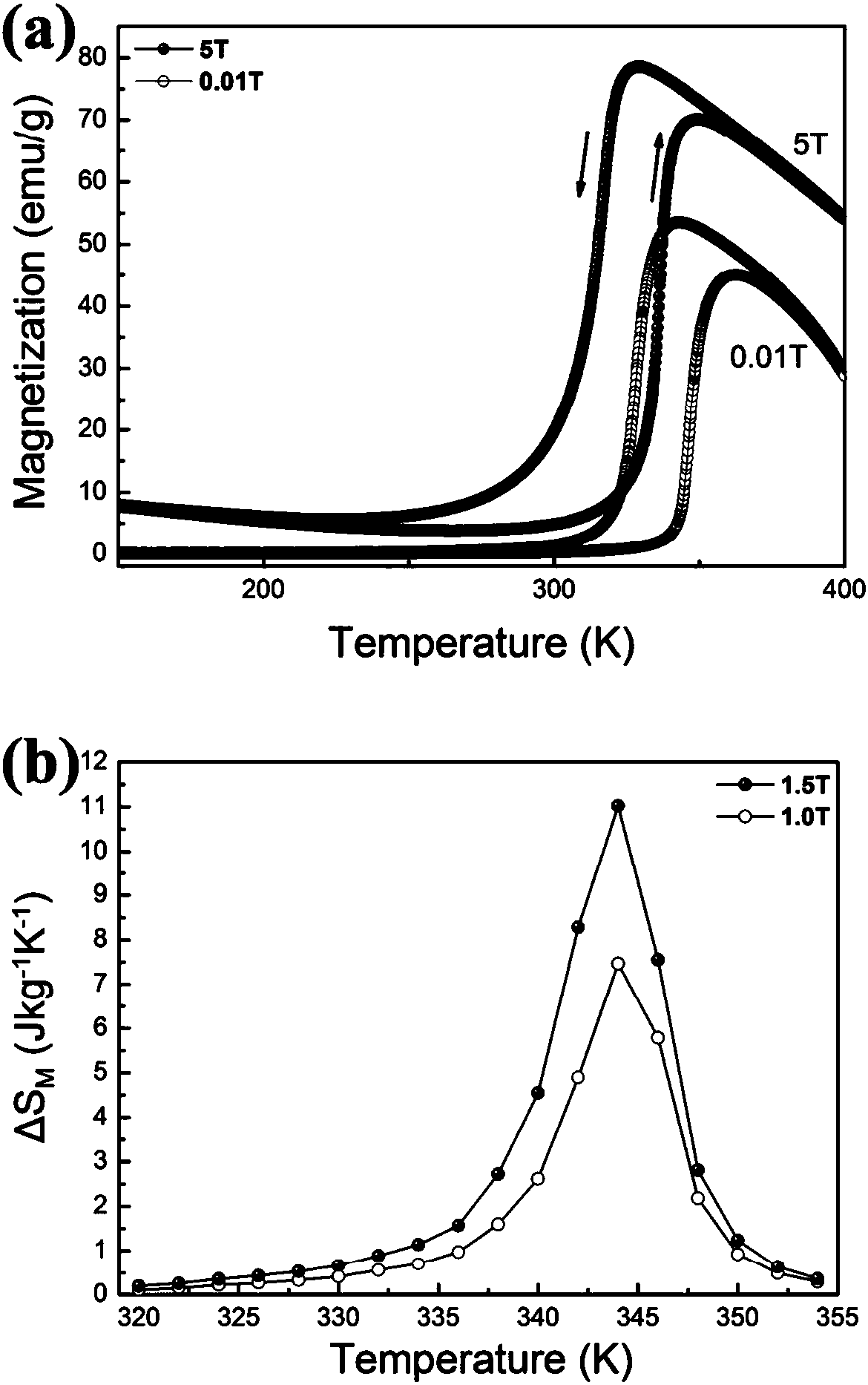

Embodiment 1

[0043] In the Mn-Ni-Sn-Co alloy strip of this embodiment, the sum of the moles of elements in the alloy strip is 100, and the molar ratio of the elements is Mn:Ni:Sn:Co=50:37:8:5, Mn 50 Ni 37 sn 8 co 5 The thickness of the alloy ribbon was 100 μm.

[0044] mn 50 Ni 37 sn 8 co 5 The preparation method of alloy thin strip, comprises the following steps:

[0045] Step 1, preparation of polycrystalline parent alloy:

[0046] (1) Mn-Ni-Sn-Co alloy thin strips, according to the molar ratio of elements Mn:Ni:Sn:Co=50:37:8:5, weigh Mn, Ni, Sn and Co respectively, and place them in a vacuum arc In the water-cooled copper crucible of the smelting furnace, place Mn at the bottom of the water-cooled copper crucible, place Ni, Sn and Co above Mn to reduce the volatilization of Mn during the smelting process, and vacuumize the chamber of the arc melting furnace to 3×10 -3 After Pa, argon gas is introduced to 0.05MPa, and the arc generated by the tungsten electrode is used for melti...

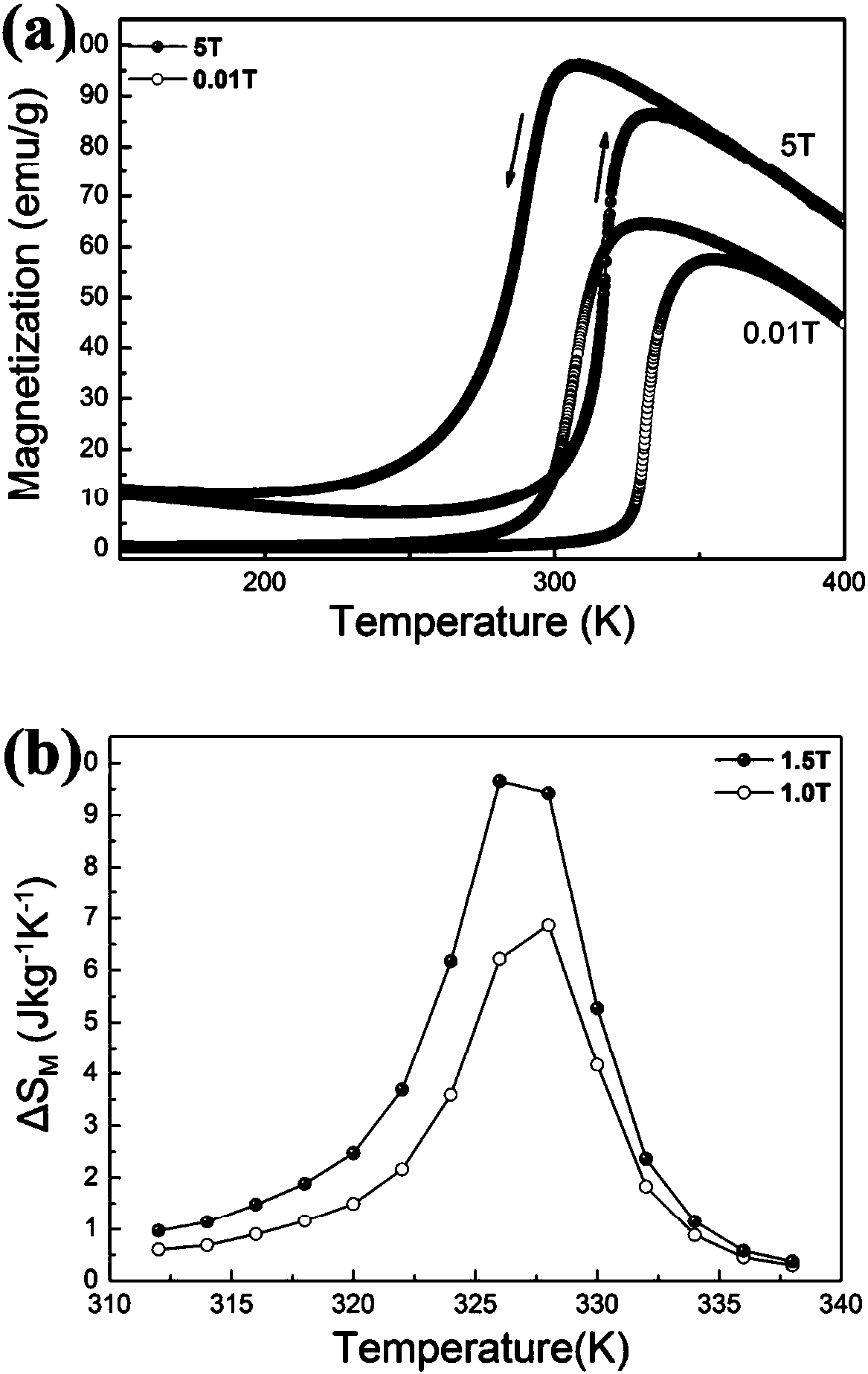

Embodiment 2

[0056] In the Mn-Ni-Sn-Co alloy strip of this embodiment, the sum of the moles of elements in the alloy strip is 100, and the molar ratio of the elements is Mn:Ni:Sn:Co=50:36:8:6, Mn 50 Ni 36 sn 8 co 6 The thickness of the alloy ribbon was 100 μm.

[0057] Mn in this example 50 Ni 36 sn 8 co 6 The preparation method of alloy thin strip, comprises the following steps:

[0058] Step 1, preparation of polycrystalline parent alloy:

[0059] (1) Mn-Ni-Sn-Co alloy strips, according to the molar ratio of elements Mn:Ni:Sn:Co=50:36:8:6, weigh Mn, Ni, Sn and Co respectively, and place them in a vacuum arc In the water-cooled copper crucible of the smelting furnace, place Mn at the bottom of the water-cooled copper crucible, place Ni, Sn and Co above Mn to reduce the volatilization of Mn during the smelting process, and vacuumize the chamber of the arc melting furnace to 3×10 -3 After Pa, argon gas is introduced to 0.05MPa, and the arc generated by the tungsten electrode is use...

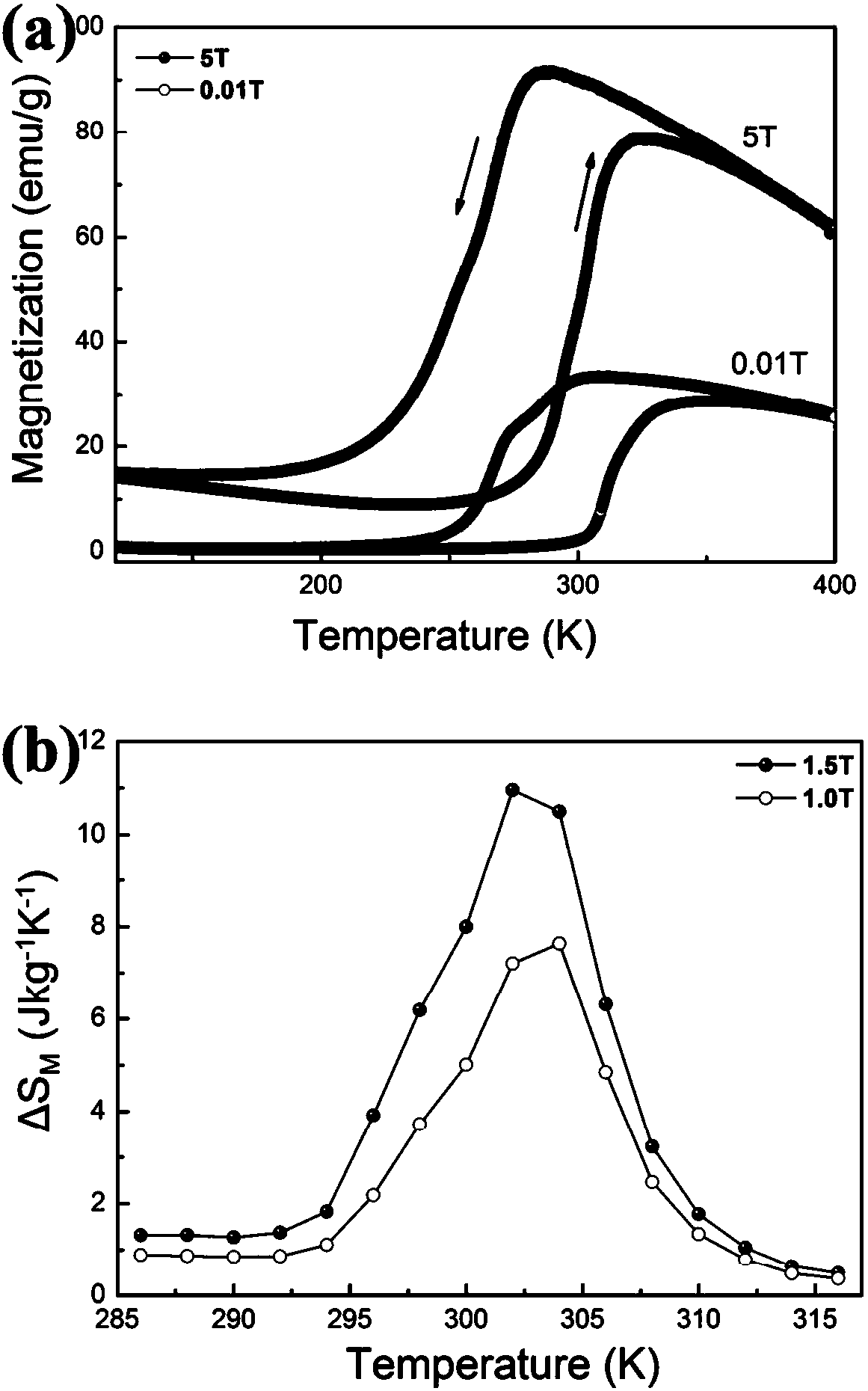

Embodiment 3

[0069] In the Mn-Ni-Sn-Co alloy strip of this embodiment, the sum of the moles of elements in the alloy strip is 100, and the molar ratio of the elements is Mn:Ni:Sn:Co=50:35:8:7, Mn 50 Ni 35 sn 8 co 7 The thickness of the alloy ribbon was 100 μm.

[0070] Mn in this example 50 Ni 35 sn 8 co 7 The preparation method of alloy thin strip, comprises the following steps:

[0071] Step 1, preparation of polycrystalline parent alloy:

[0072] (1) Mn-Ni-Sn-Co alloy thin strips, according to the molar ratio of elements Mn:Ni:Sn:Co=50:35:8:7, weigh Mn, Ni, Sn and Co respectively, and place them in a vacuum arc In the water-cooled copper crucible of the smelting furnace, place Mn at the bottom of the water-cooled copper crucible, place Ni, Sn and Co above Mn to reduce the volatilization of Mn during the smelting process, and vacuumize the chamber of the arc melting furnace to 3×10 -3 After Pa, argon gas is introduced to 0.05MPa, and the arc generated by the tungsten electrode is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com