Construction method for pre-paving and inverted bonding of composite macromolecule waterproof roll on piled raft foundation

A composite polymer and waterproof membrane technology, which is applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of high construction cost, affecting construction progress, and high requirements for the base layer, so as to reduce construction costs, improve construction progress, and improve the base layer. less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the construction method of pre-laying anti-adhesive composite polymer waterproof membrane on pile raft foundation, the construction method includes the following steps:

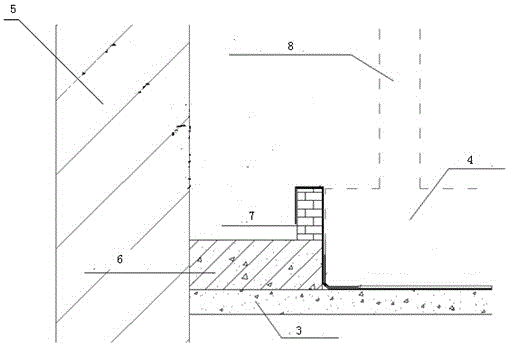

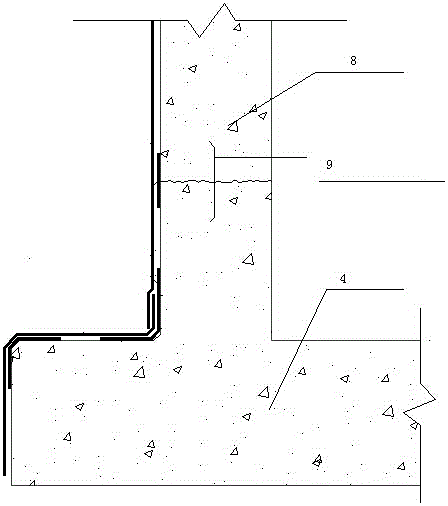

[0029] (1) Cushion construction: according to the design requirements, the concrete pouring construction of the cushion is carried out, and a 145-155mm thick C20 concrete cushion is poured;

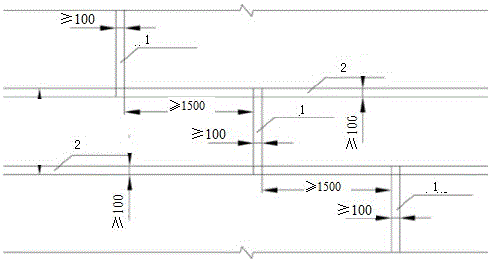

[0030] (2) Cleaning of the base layer and positioning of the wires: remove dust and oil on the surface of the base layer to ensure that the base layer is solid, flat and free of debris; then, the control line for laying the coiled material is released on the base layer to avoid misalignment, skew, etc.

[0031] (3) Treatment of the details of deformation joints and yin and yang corners: set up an additional layer of coiled material at the junction of plane and vertical surfaces, deformation joints, construction joints, and pipe roots, and cut them on site according to requirements. The addition...

Embodiment 2

[0039] The Chengxing complex project consists of Chengxing Garden, Chengxing Plaza and Chengxing Building, with a total construction area of 435,000㎡, of which the floor area of the basement is about 23,000㎡ for Chengxing Garden, and about 13,000㎡ for Chengxing Plaza. 10,000 ㎡, Chengxing Building: about 14,000 ㎡, a total of about 50,000 ㎡; the design requirements for the original waterproof layer of the basement floor are:

[0040] 150mm thick C20 concrete cushion

[0041] 3mm thick polyester tire SBS modified bitumen waterproof membrane two layers

[0042] 50 thick C20 fine stone concrete leveling layer

[0043] Cast-in-place reinforced concrete floor

[0044] In this embodiment, according to the construction method of pre-laying anti-adhesive composite polymer waterproof coiled material on the pile raft foundation of the present invention, the design requirements for the waterproof layer of the basement floor are changed to:

[0045] 150mm thick C20 concrete cushion ...

Embodiment 3

[0053] This embodiment is illustrated by engineering examples. This construction method has been successfully applied in three engineering projects, Chengxing Garden, Chengxing Plaza, and Chengxing Building, Jiangyin Chengxing Complex in Wuxi City. This project is located on the east side of Huashan Road in Jiangyin City. On the south side of Qianlu Road, the total construction area is about 435,000 square meters, of which Chengxing Garden has a construction area of about 200,000 square meters. A total of 6 buildings are residential projects. It is 33-34 floors; Chengxing Plaza has a construction area of about 85,000 square meters, with three floors underground and seven floors above ground; Chengxing Building has a construction area of about 200,000 square meters, three floors underground, 50 floors above ground, and four floors in the podium. At present, Chengxing Garden has entered the decoration construction stage, Chengxing Plaza has been constructed to the fourth fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com