Hydraulic-balance screw pump assembly

A technology of hydraulic balance and screw pump, which is applied to pump components, rotary piston type/oscillating piston type pump components, pumps, etc. It can solve the problems of non-wear resistance, short service life, high power, etc., and achieve energy saving and service life. Improved service life and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

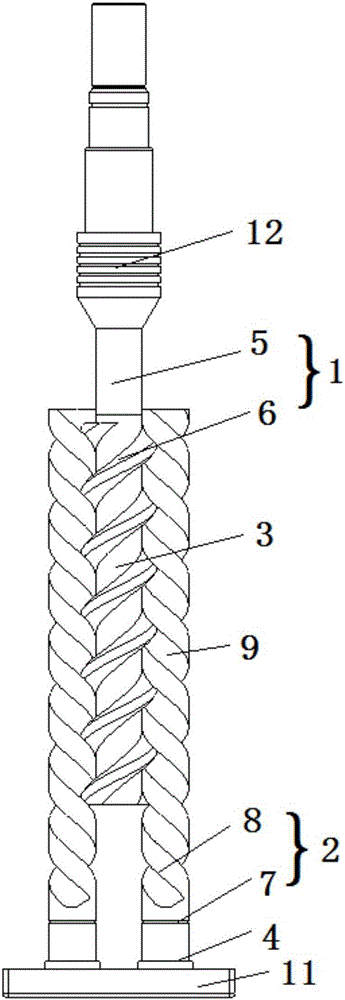

[0016] Examples such as figure 1 , figure 2 The hydraulically balanced screw pump assembly shown includes a driving screw 1 and a driven screw 2 that is engaged with the driving screw 2. The driven screw 2 is axially provided with a liquid hole 10 that runs through the entire rod, that is, it runs through the entire rod. Root follower screw 2. The diameter of the liquid hole 10 is 0.3-6mm. The liquid hole 10 is used to introduce the high pressure in the high pressure area to counteract the axial force of the driven screw 2 during operation through hydraulic balance.

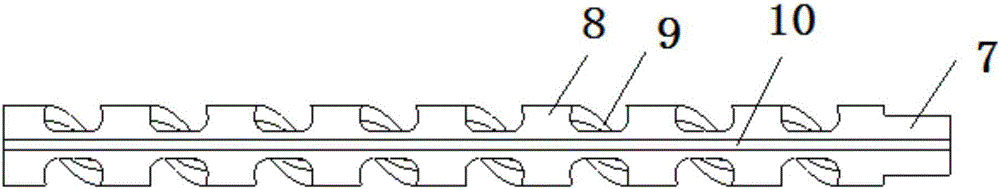

[0017] The driving screw 1 includes a driving end 5 and a driving helical segment 6 extending axially downward from the lower end surface of the driving end 5, and the driving helical segment 6 is provided with a driving helical groove 3; the driven screw 1 includes a driven end 7 and a The driven helical section 8 extending axially upward on the upper end surface of the driven terminal 7 is provided with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com