Experimental test method for gas reservoir reverse imbibition water blocking damage evaluation under high-temperature and high-pressure condition

A high-temperature, high-pressure, water-locking damage technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as gas reservoir development process not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further illustrate the present invention according to accompanying drawing and embodiment below.

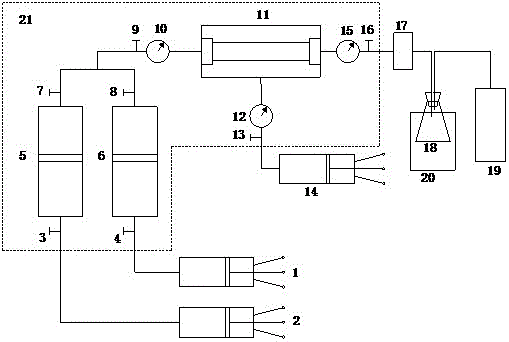

[0022] The experimental test method for evaluating the damage of gas reservoir reverse osmosis absorption water lock under high temperature and high pressure conditions is completed by using the water lock effect experimental measurement device, and the water lock effect experimental measurement device ( figure 1 ) consists of a core holder 11, a water sample intermediate container 5, a gas sample intermediate container 6, a water displacement pump 2, a gas displacement pump 1, an inlet pressure gauge 10, an outlet pressure gauge 15, a back pressure regulator 17, and a water meter instrument 18, gas meter 19, condenser 20, confining pressure gauge 12, confining pressure displacement pump 14, and constant temperature box 21. The inlet end of the core holder 11 is connected to the water sample intermediate container 5 through the inlet pressure gauge 10 , water displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com