Method for forming 3D NAND flash memory

A flash memory and graphics technology, applied in the manufacturing of electrical components, electro-solid devices, semiconductor/solid-state devices, etc., can solve the problems of increased process difficulty, no advantages of 1YNAND products, and increased product reliability requirements, and can reduce the size, Increase process difficulty and improve the effect of equivalent storage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

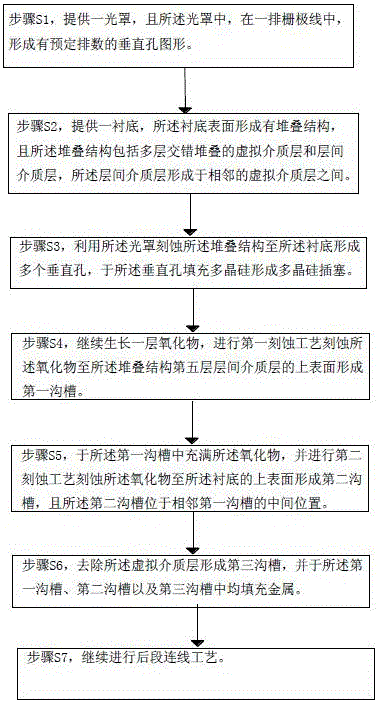

[0029] Such as figure 1 As shown, the present embodiment relates to a method for forming a 3D NAND flash memory, and the method specifically includes the following steps:

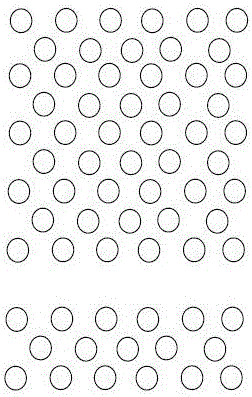

[0030] In step S1, a photomask is provided, and in the photomask, a predetermined number of rows of vertical hole patterns are formed in a row of gate lines; preferably, the predetermined number of rows is 9 rows, that is, in the photomask, In a row of gate lines, 9 rows of vertical hole patterns are formed, such as image 3 structure shown.

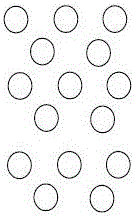

[0031] figure 2 It is a schematic structural diagram of an existing photomask forming vertical holes. It is obvious that the arrangement of vertical holes formed by the photomask in this embodiment is more optimized, which can save area and increase storage density.

[0032] In ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com