Bidirectional integrated embedded-type POP packaging structure and manufacturing method thereof

A packaging structure and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as poor electrical properties, easily deformed substrate thickness, unfavorable packaging integration, etc., and achieve high support strength , better electrical and heat dissipation performance, and better product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

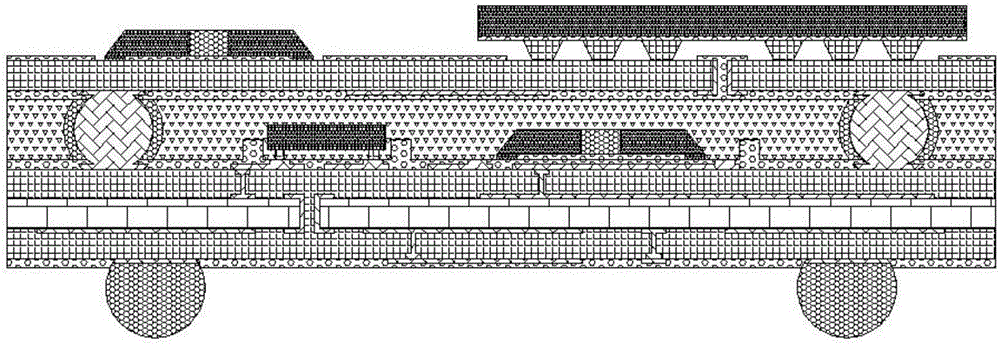

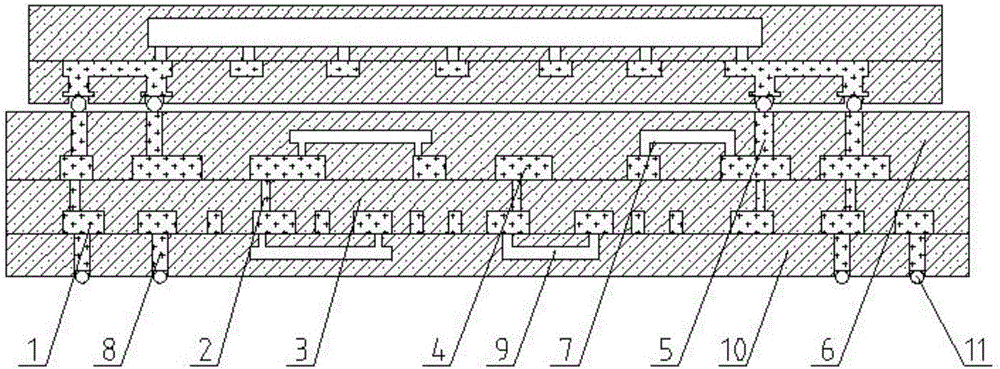

[0047] Such as figure 2 As shown, a bidirectional integrated embedded POP package structure in this embodiment includes a first package body and a second package body, the first package body includes a first circuit layer 1, and the first circuit layer 1. A first connection copper post 2 is provided on the front side. The first circuit layer 1 and the first connection copper post 2 are surrounded by a first insulating material 3. The front side of the first insulating material 3 is provided with a second circuit layer 4. , the front of the second circuit layer 4 is provided with a second connection copper column 5 and a first component 7, and the second circuit layer 4, the second connection copper column 5 and the first component 7 are surrounded by a second Insulating material 6, the back of the first insulating material 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com