Harmonic cancellation PWM generation method

A technology of harmonic elimination and modulation wave, applied in the field of harmonic elimination PWM generation, can solve the problems of large harmonic content, inaccurate switching, slow response of SHEPWM speed regulation, etc., to achieve smooth motor torque output, improve control accuracy, and easy The effect of harmonic cancellation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

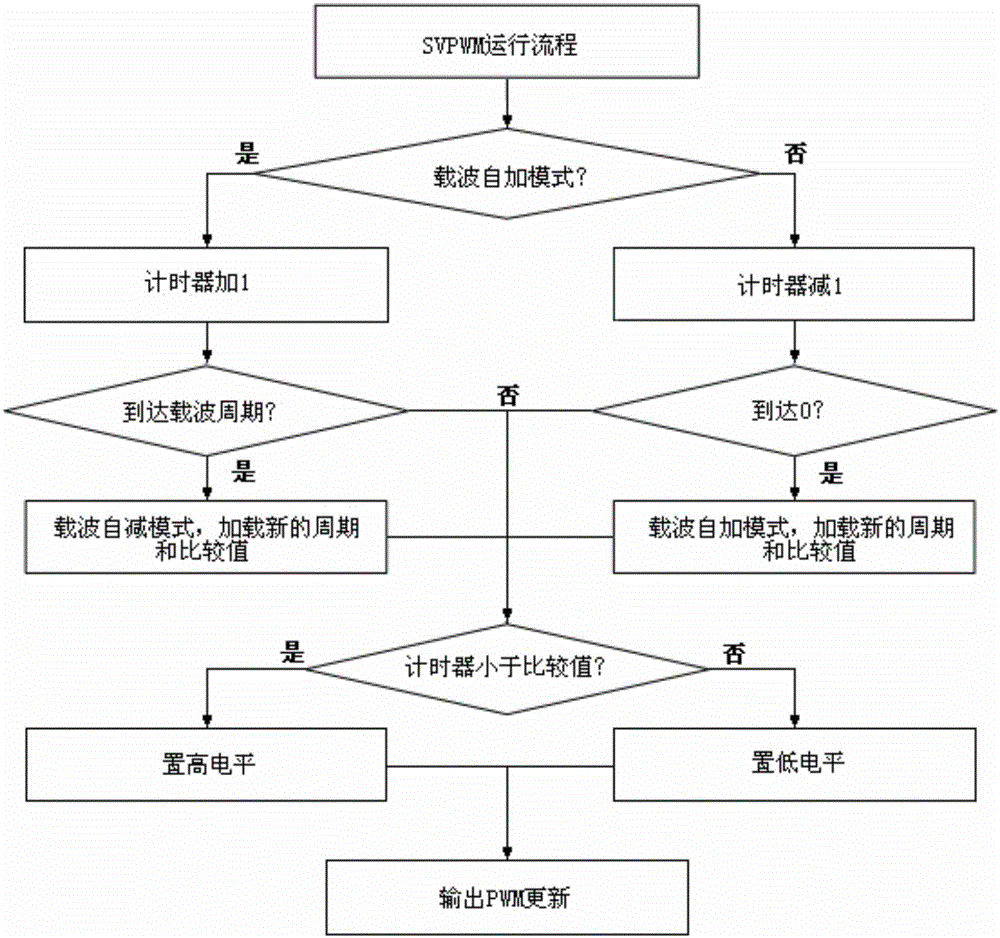

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] In this embodiment, the control system is realized by DSP plus programmable logic controller. The motor control algorithm and PWM operation are all completed by DSP, and then transmitted to the programmable logic controller through bus communication, and the programmable logic controller accurately sends out control pulses Wave. The programmable logic controller can be FPGA or CPLD, etc. In this embodiment, FPGA is selected for illustration.

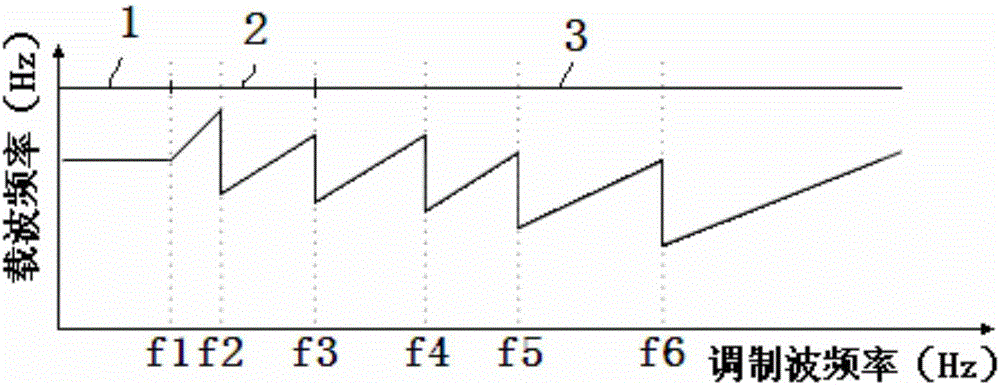

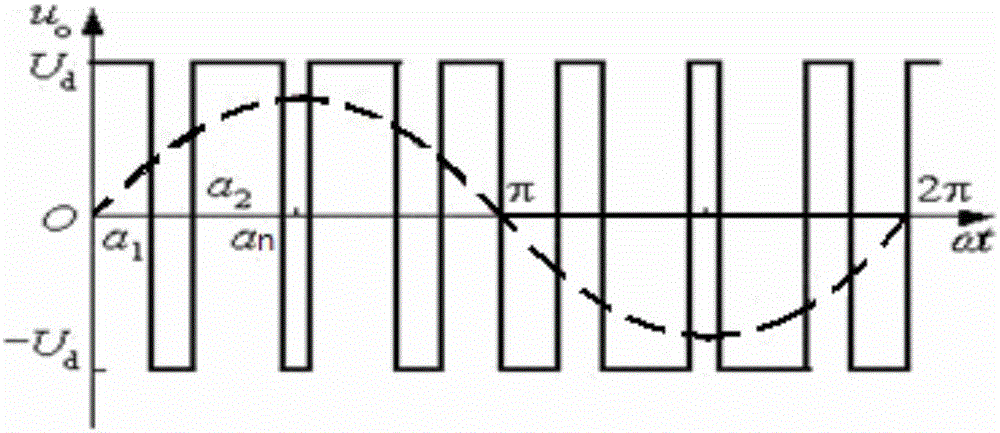

[0036] Such as figure 1 As shown, a harmonic elimination PWM generation method, within the range of variable frequency speed regulation, the modulation frequency is divided into three stages by the control system: the first stage 1 of low frequency operation, the second stage 2 of low frequency operation, and the stage 3 of medium and high frequency operation part;

[0037] In the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com