Compression storage process for expanded tobacco stem products

A technology for expanding tobacco stems and products, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing. It can solve the problems of inconvenient transportation, high storage costs, and poor suction, and achieves reduced storage costs, saved storage space, and is easy to loosen later. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

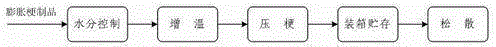

[0034] A compressed storage process for expanded tobacco stem products, the process steps are as follows:

[0035] A. Moisture control, using a drying cylinder to dry the expanded tobacco stem products (expanded stem particles, expanded stem strips or expanded stem shreds) to a moisture content of 13wt%;

[0036] B. Increase temperature, use 80°C hot air to heat the expanded tobacco stem product to 55-75°C;

[0037] C. Press the stem, compress the expanded tobacco stem product to 15% to 25% of the original volume, and make a rectangular block with a thickness of 100mm to 200mm, a length of 1100mm, and a width of 700mm

[0038] D. Packing and storing, after packing the compressed stalks into boxes with the same quantity per box, store them under ventilated conditions with a temperature of ≤38°C and a humidity of ≤70% through logistics;

[0039] E. Loose recovery, the stored compressed stalks will be used in subsequent processes after being loosened and recovered in vacuum.

Embodiment 2

[0041] The expanded stalks with a moisture content of 26wt% are dried by HT+drum to a moisture content of 13.5wt%, heated to 48°C by hot air, and compressed to 25% of the original volume by a KY161 pre-pressing machine to produce a thickness of 175mm. , 1100mm in length and 700mm in width; each 4 pieces should be packed into a corrugated box; stored for 1 year under ventilated conditions with a temperature of ≤38°C and a humidity of ≤70%; when in use, loosen and recover by heating with 915MHz microwave after unpacking Volume is enough.

Embodiment 3

[0043] The expanded stalk granules with a moisture content of 29wt% are dried to a moisture content of 15wt% through a Venturi tube + expansion tower, heated to 90°C by 2450MHz microwave, and compressed to 80% of the original volume by a single hydraulic pre-compressor. Make stalks with a thickness of 50mm, a length of 1100mm, and a width of 700mm; put 14 pieces into a corrugated box; store for 2 years under ventilated conditions with a temperature of ≤38°C and a humidity of ≤70%; when used, pass through a vacuum after unpacking The way of regaining moisture is to loosen and restore the volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com