Special bottom opening centrifuge tube device used during centrifugation

A centrifuge tube and special technology are applied in the field of micro-precipitation acquisition devices, which can solve the problems of difficult concentration of solid phase substances, too large area, inconvenience, etc., and achieve the effects of saving acquisition time, improving processing efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The volume of the device can be made of materials such as metal, plastics, glass, sintering and the like as required by the straight pipe 2, the taper pipe 3, the small straight pipe 4, and the bottom opening cover 5.

[0021] The method for separating the solid phase substance in the mixed liquid phase using the above-mentioned device specifically includes the following steps:

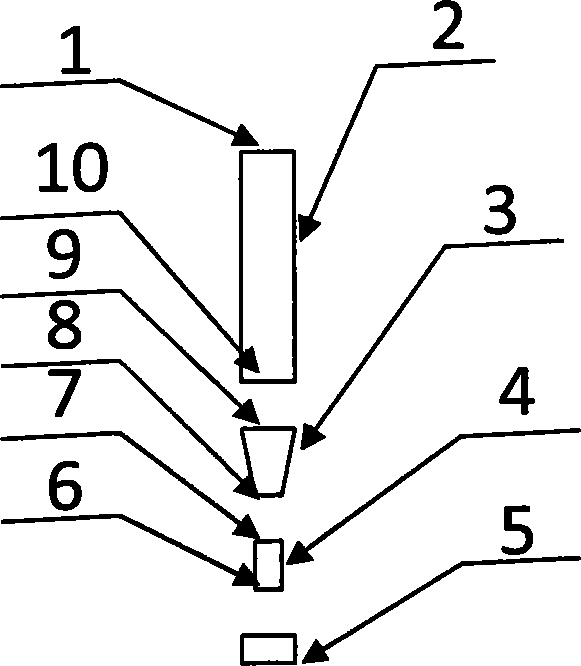

[0022] Step 1, the lower end 10 of the straight pipe is sealed with the upper end 9 of the tapered pipe, the lower end 8 of the tapered pipe is connected with the upper end 7 of the small straight pipe, and the lower end 6 of the small straight pipe is connected with the bottom opening cover 5 in a sealed manner.

[0023] Step 2, pour the mixed liquid phase to be separated into the straight pipe from the upper end 1 thereof.

[0024] Step 3, The tube is centrifuged on the machine to form solid and liquid phase separation.

[0025] Step 4, from Take out the tube from the machine, pour it ou...

Embodiment 2

[0029] The volume of the device can be made of materials such as metal, plastics, glass, sintering and the like as required by the straight pipe 2, the taper pipe 3, the small straight pipe 4, and the bottom opening cover 5.

[0030] The method for separating the solid phase substance in the mixed liquid phase using the above-mentioned device specifically includes the following steps:

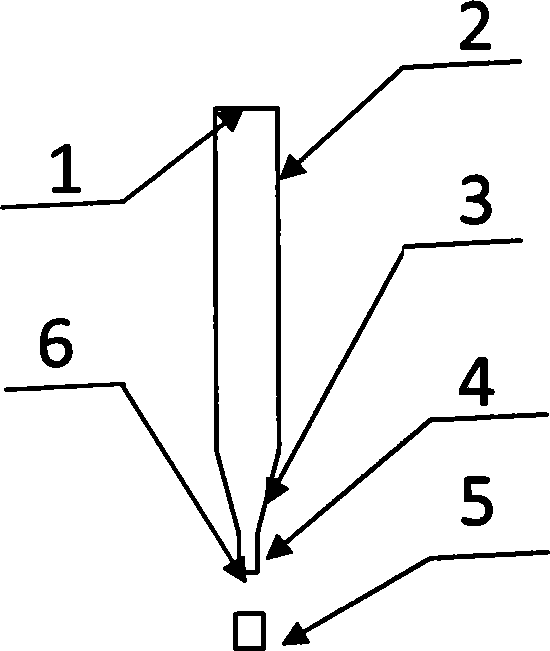

[0031] In step 1, the straight pipe 2, the tapered pipe 3, and the small straight pipe 4 can be directly formed as a whole, and the lower end 6 of the small straight pipe is sealed and connected with the bottom opening cover 5.

[0032] Step 2, pour the mixed liquid phase to be separated into the straight pipe from the upper end 1 thereof.

[0033] In step 3, the tube is centrifuged on a machine to separate solid and liquid phases.

[0034] Step 4, take out the tube from the centrifuge, pour out from the upper end 1 of the straight tube, or use a straw to suck out the upper part of the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com