Liftable cantilever type sewage pipe welding equipment

A technology for welding equipment and sewage pipes is applied in the field of cantilever liftable sewage pipe welding equipment, which can solve the problems of unstable welding accuracy and low welding production level, and achieve the effects of simple structure, improved safety, and convenient query.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0018] Embodiment: In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

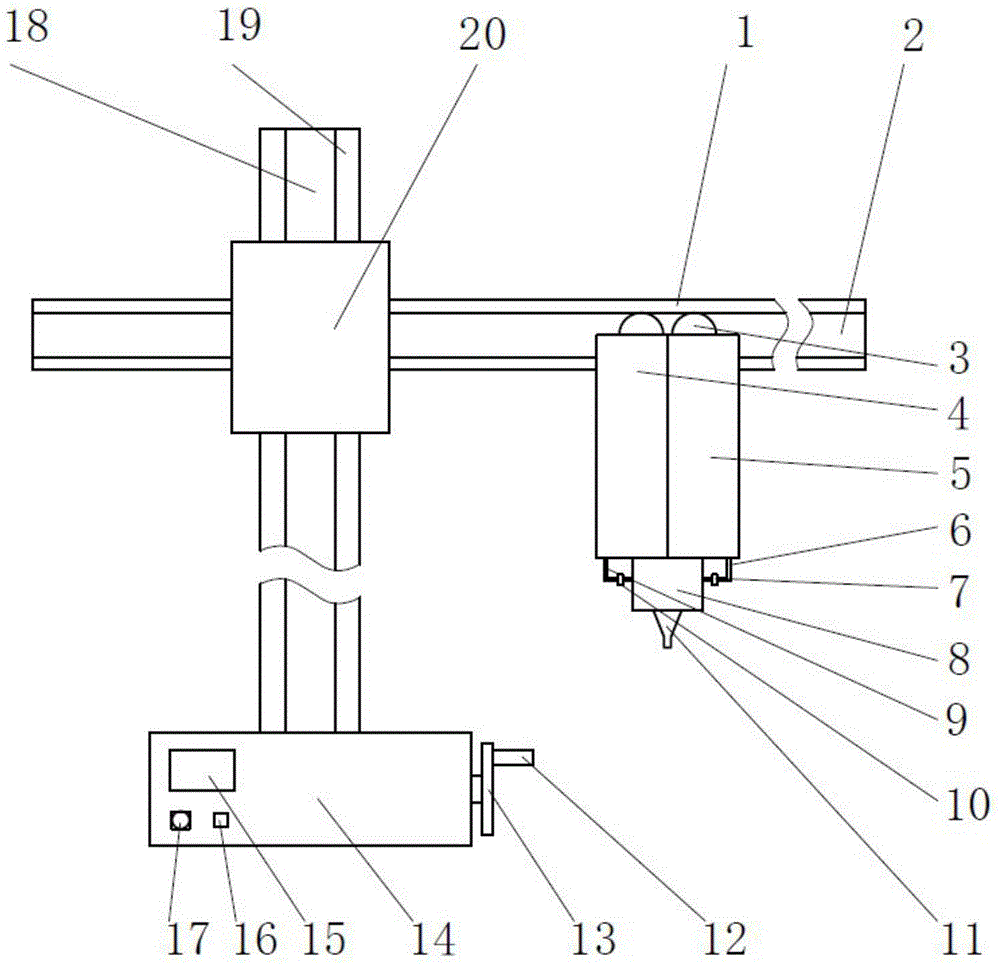

[0019] Such as figure 1 As shown, the present invention provides a cantilever type lifting sewage pipe welding equipment, including welding beam 1, slide rail 2, sliding roller 3, argon storage tank 4, combustible gas storage tank 5, combustible gas pipe 6, electric control right Valve 7, output tank 8, argon tube 9, electric control left valve 10, welding contact 11, rocker handle 12, turntable 13, control device 14, display screen 15, power switch 16, emergency stop button 17, vertical rail 18, The welding column 19 and the driving device 20, the welding beam 1 is installed on the driving device 20, the welding column 19 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com