Sequencing-batch type mobile filtration bed sewage treatment method and device

A sewage treatment method and sequencing batch technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor sedimentation separation effect, reactor failure, activated sludge problems such as loss, to avoid regular backwash operations, improve efficiency, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

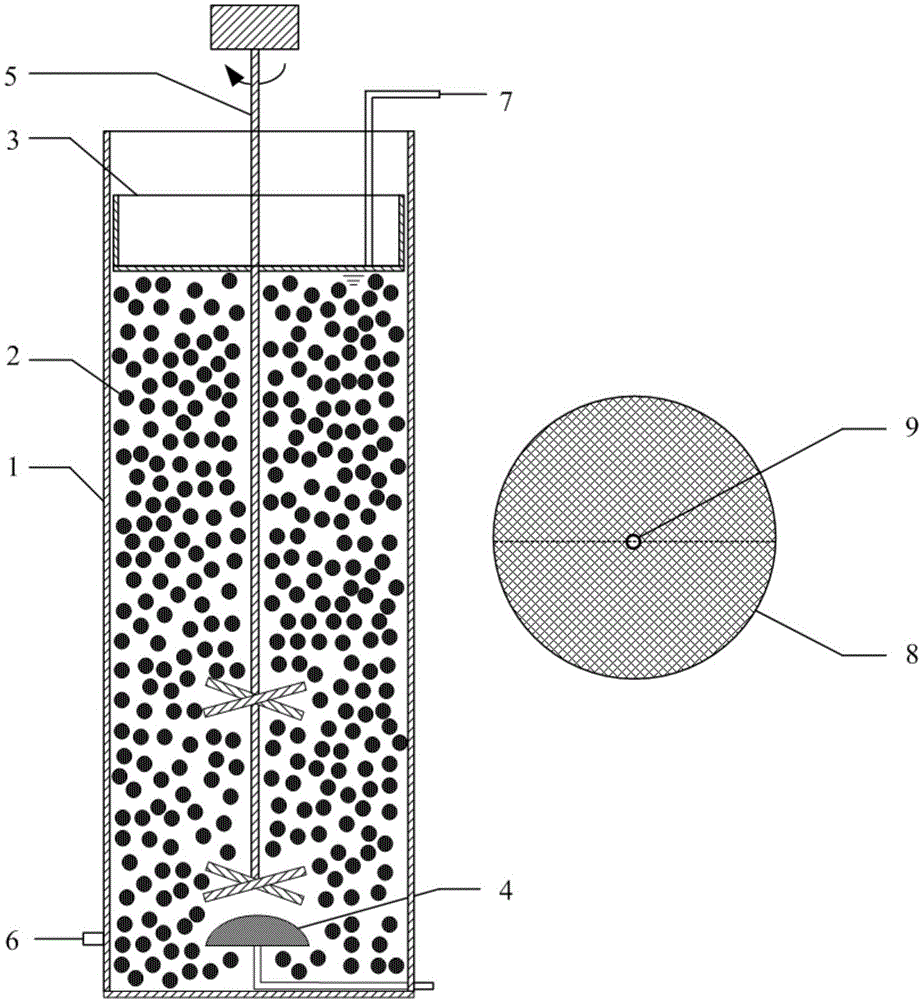

[0017] In order to clearly illustrate the features of the technical solution, the technical solution will be described below through a specific implementation manner combined with the accompanying drawings.

[0018] as attached figure 1 As shown, the sequence batch mobile filter bed sewage treatment device is composed of a reactor body 1, a medium packing 2, and a movable water collecting member 3. The bottom of the reactor body 1 is provided with an aerator 4; the inside of the reactor body 1 is equipped with an agitator 5; The medium filler 2 is polypropylene regenerated plastic particles, the specific gravity before and after filming is lower than that of water, and the filling rate is 60%. The material of the movable water-collecting member 3 is stainless steel; the movable water-collecting member 3 has a built-in outlet pipe 7; the mesh number of the screen 8 at the bottom of the movable water-collecting member 3 is 16, and the center of the screen 8 is provided for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com