A method for treating flue gas wet desulfurization wastewater

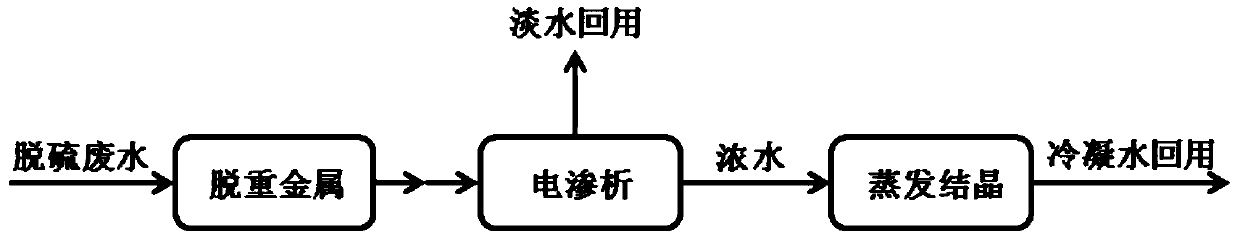

A wet desulfurization and waste water technology, which is applied in the field of flue gas desulfurization waste water and desulfurization zero discharge, can solve the problems of non-direct discharge, complex system, corrosion of equipment and pipelines, etc., to reduce load, reduce use cost, and reduce slag volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

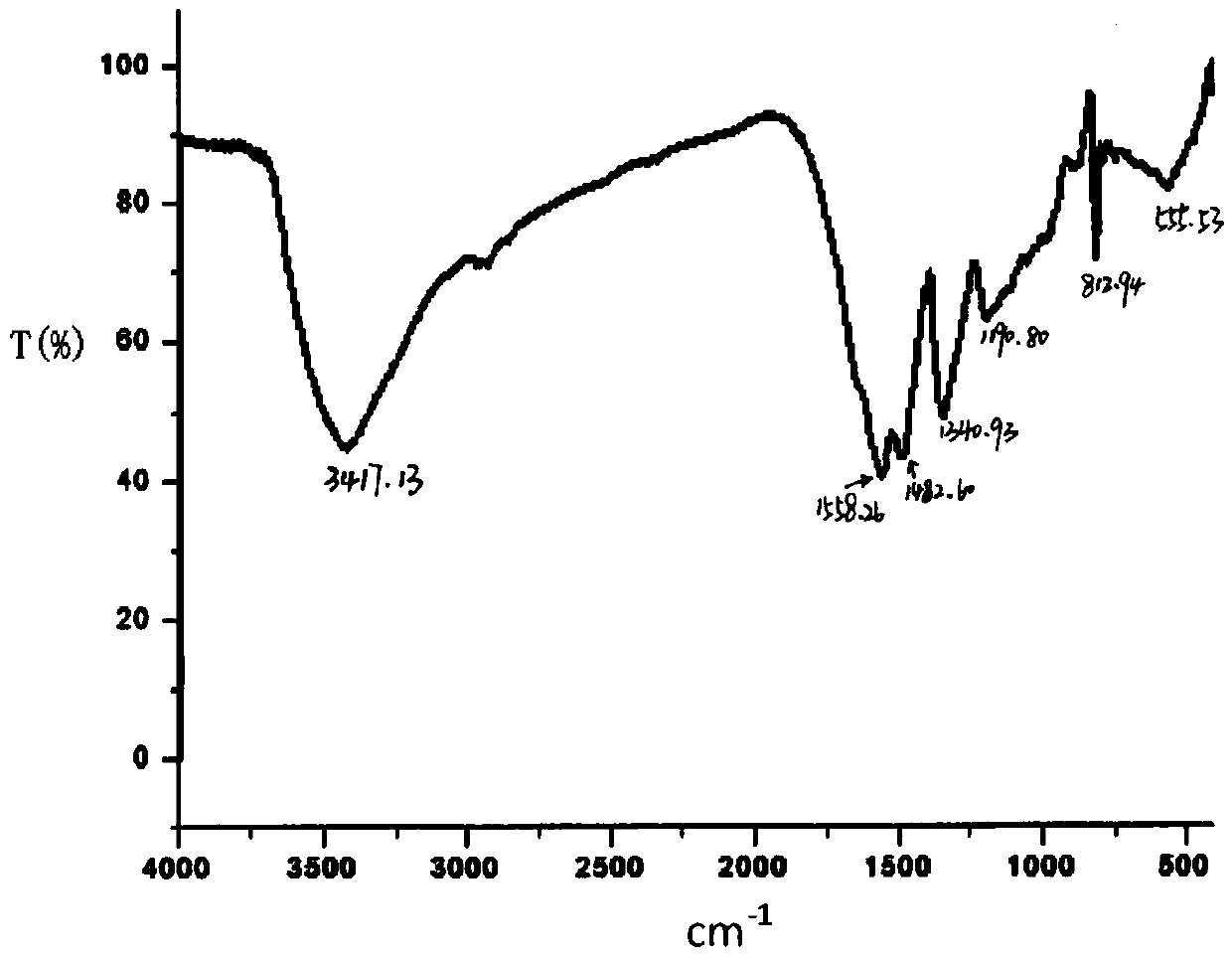

[0034] Synthesis of SHO resin A: It is obtained by polymerizing melamine and thiophene formaldehyde in dimethyl sulfoxide. The specific synthesis steps are as follows: add 100 grams of melamine and 133.4 grams of thiophene formaldehyde into a 500 milliliter round low flask, then add 250 milliliters of dimethyl sulfoxide solution, and heat and stir the mixture at 130 degrees Celsius under a nitrogen atmosphere for 15 hours. After cooling, the pale yellow solid was filtered out, washed with water and ethanol, and dried to obtain 210 g of a polymer product.

[0035] Synthesis of SHO resin B: obtained by polymerizing melamine and furan formaldehyde in dimethylformamide. The specific synthesis steps are as follows: add 100 grams of melamine and 114.3 grams of furfuralaldehyde into a 500 milliliter round low flask, then add 300 milliliters of dimethylformamide solution, and heat and stir the mixture at 110 degrees Celsius under nitrogen for 12 hours. After cooling, the pale yellow ...

Embodiment 2

[0038] Add 8 grams of polymer SHO resin C material into a beaker containing 10 kg of desulfurization wastewater (pH 4-6.5, chloride ion content: about 10000ppm), stir and react for 30 minutes, after flocculation, sedimentation and filtration, after treatment The wastewater meets the heavy metal discharge standard for desulfurization wastewater (DL / T 997-2006). After the heavy metal is removed, the wastewater enters the softening tank, and Na 2 CO 3 After stirring and reacting, it overflows into the clarifier and flows into the clear water tank after being clarified, and then enters the precision filter for filtration with a pump; the sludge at the bottom of the clarifier is calcium carbonate and is regularly pumped to the desulfurization tower for reuse; the water after the precision filter enters the electric The dialyzer performs dechlorination treatment, and the treated fresh water (about 8 kg, chloride ion content: 45000ppm) enters the preheater; the high-salt concentrate...

Embodiment 3

[0041] Add 10 grams of polymer SHO resin A material into a beaker containing 10 kg of desulfurization wastewater (pH 4-6.5, chloride ion content: about 10000ppm), stir and react for 40 minutes, after flocculation, sedimentation and filtration, after treatment The wastewater meets the heavy metal discharge standard for desulfurization wastewater (DL / T 997-2006). After the heavy metal is removed, the wastewater enters the softening tank, and Na 2 CO 3 After stirring and reacting, it overflows into the clarifier and flows into the clear water tank after being clarified, and then enters the precision filter for filtration with a pump; the sludge at the bottom of the clarifier is calcium carbonate and is regularly pumped to the desulfurization tower for reuse; the water after the precision filter enters the electric The dialyzer performs dechlorination treatment, and the treated fresh water (about 7 kg, chloride ion content: 40000ppm) enters the preheater; the high-salt concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com