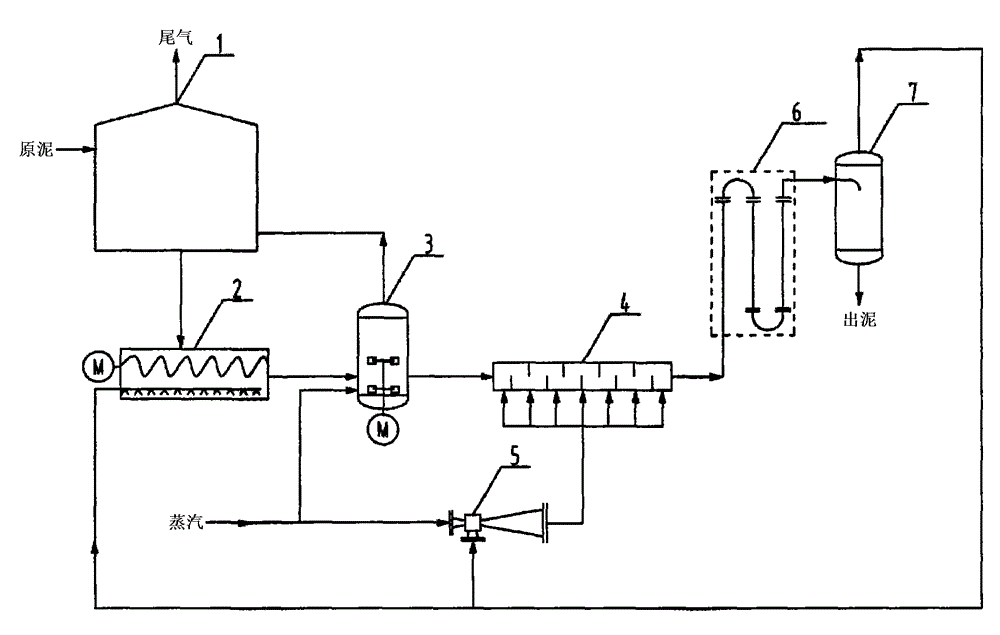

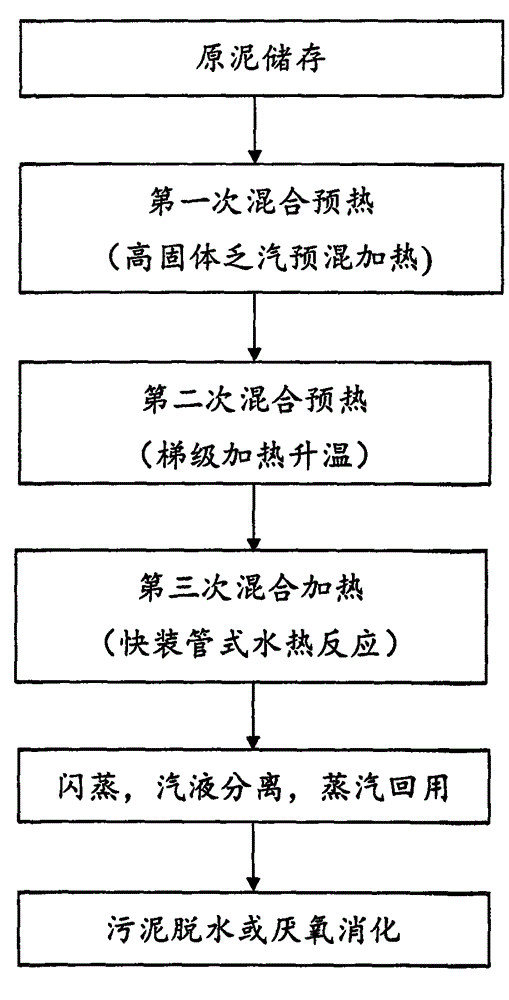

Multi-section tubular type sludge rapid thermal hydrolysis treatment process

A treatment process, thermal hydrolysis technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high unit investment cost, large floor area, and large number of equipment, etc. Achieve the effect of less equipment, less power equipment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0053] Embodiment 2. In the fast-packed tubular hydrothermal reactor, the reaction temperature is 180° C., and the residence time is 10 min. Other reaction conditions are the same as in Embodiment 1. As a result of the reaction, total solids (TS) were removed by 5.6%, total organic solids (TVS) were removed by 10%, suspended solids (SS) were dissolved by 18%, and supernatant COD (SCOD) was 33000 mg / L. The solids content of the dewatered cake was 51%.

Embodiment 3

[0054] Embodiment 3. In the fast-packed tubular hydrothermal reactor, the reaction temperature is 190° C., and the residence time is 10 min. Other reaction conditions are the same as in Embodiment 1. As a result of the reaction, total solids (TS) were removed by 7.2%, total organic solids (TVS) were removed by 15%, suspended solids (SS) were dissolved by 26%, and supernatant COD (SCOD) was 45000 mg / L. The solids content of the dewatered cake was 62%.

Embodiment 4

[0055] Embodiment 4. In the fast-packed tubular hydrothermal reactor, the reaction temperature is 170° C., the residence time is 10 min, and other reaction conditions are the same as in Embodiment 1. As a result of the reaction, total solids (TS) were removed by 5.7%, total organic solids (TVS) were removed by 10.2%, suspended solids (SS) were dissolved by 15.7%, and supernatant COD (SCOD) was 29500 mg / L. The solids content of the dewatered cake was 43%.

[0056] Example 5. The raw sludge at 20°C is mixed and preheated with flash steam for the first time at the inlet of the raw sludge pump, the residence time is 5min, and the temperature rises to 75°C; The second mixing preheating, the residence time is 4min, and the temperature rises to 118°C; then the third mixing and heating is carried out in the secondary static mixer with the mixed steam, the residence time is 6min, and the temperature rises to 172°C; The hydrothermal reactor maintains the temperature for 5 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com