Preparation method of composite conductive silver-lanthanum nickelate thin-film material

A technology of composite conductive and thin film materials, applied in the field of preparation of silver-lanthanum nickelate composite conductive thin film materials, can solve problems such as polarization fatigue of ferroelectric thin films, and achieve the effects of low cost, simple process and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

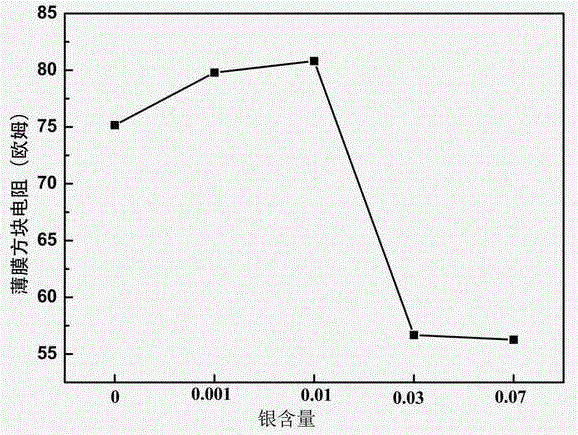

Embodiment 1

[0009] (1) Use ethylene glycol methyl ether as solvent, and prepare green transparent solution with lanthanum nitrate, nickel acetate and silver nitrate as solute, in which La 3+ 、Ni 2+ and Ag + The molar ratio of La is 1:1:0.001, La 3+ The molar concentration is 0.1mol / L; (2) Drop the green transparent solution prepared in step (1) onto the substrate for spin-coating, first spin-coat at 1000 rpm for 9 seconds, and then spin-coat at 4000 rpm Spin coating at a rate of 50 seconds to obtain a precursor wet film; (3) put the precursor wet film obtained in step (2) into a muffle furnace and anneal at 750 ° C for 5 minutes; (4) repeat steps (2) and (3) The silver-lanthanum nickelate composite conductive thin film material with the required thickness was prepared six times, and the annealing time of the last time was extended to 30 minutes.

Embodiment 2

[0011] (1) Use ethylene glycol methyl ether as solvent, and prepare green transparent solution with lanthanum nitrate, nickel acetate and silver nitrate as solute, in which La 3+ 、Ni 2+ and Ag + The molar ratio of La is 1:1:0.03, La 3+ The molar concentration is 0.1mol / L; (2) Drop the green transparent solution prepared in step (1) onto the substrate for spin-coating, first spin-coat at 1000 rpm for 9 seconds, and then spin-coat at 4000 rpm Spin coating at a rate of 50 seconds to obtain a precursor wet film; (3) put the precursor wet film obtained in step (2) into a muffle furnace and anneal at 750 ° C for 5 minutes; (4) repeat steps (2) and (3) The silver-lanthanum nickelate composite conductive thin film material with the required thickness was prepared six times, and the annealing time of the last time was extended to 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com