Method for preparing oxidation pellet with municipal sludge and ferruginous waste

A technology of municipal sludge and oxidized pellets, which is applied in the direction of improving process efficiency, can solve the problems of difficult and harmless treatment and resource utilization of municipal sludge and iron-containing waste, and achieves easy promotion and use, good performance, The effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

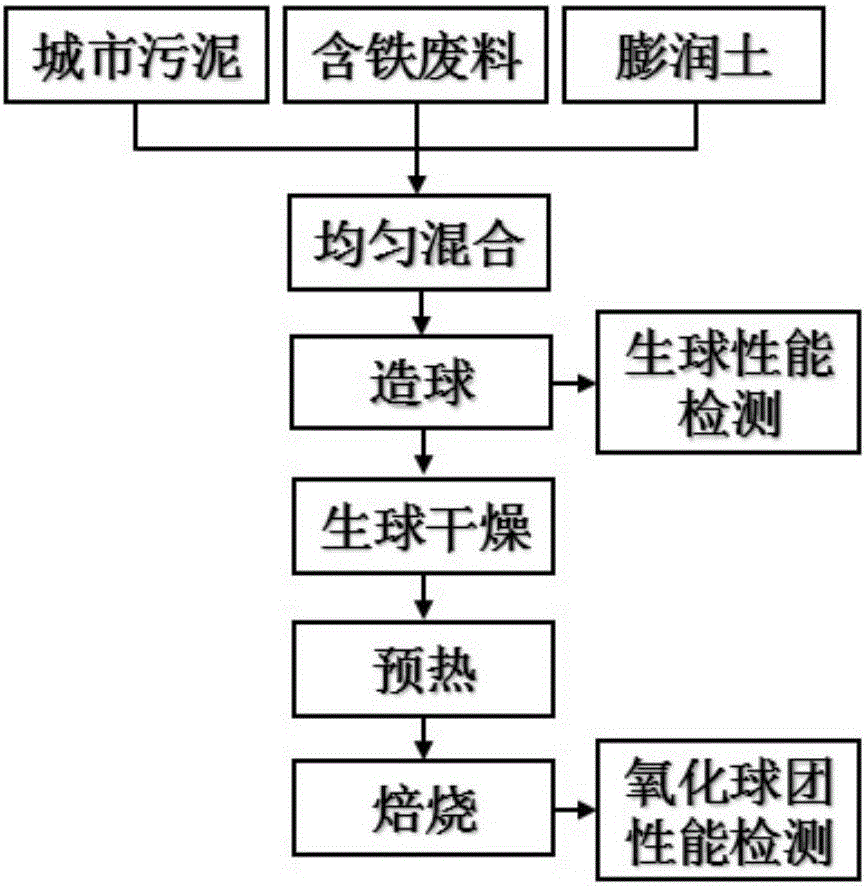

[0036] like figure 1 As shown, a method for preparing oxidized pellets from municipal sludge and iron-containing waste is characterized in that it includes the following raw materials and their mass parts:

[0037] 5 parts of municipal sludge;

[0038] 92 parts of iron-containing waste;

[0039] 3 parts bentonite;

[0040] The water content of the municipal sludge is 35%.

[0041] The iron-containing waste includes blast furnace gas ash, converter sludge, sintering dedusting ash and sulfuric acid slag; the mass ratio of the blast furnace gas ash, converter sludge, sintering dedusting ash and sulfuric acid slag is: 16:18:32:34 .

[0042] Carry out the following steps with the above raw materials:

[0043] 1) Mix the weighed raw materials; the mixing process uses a mixing truck with a rotating speed of 15 r / min and a time of 8 minutes.

[0044] 2) Put the mixed raw materials obtained in step 1) into a disc pelletizer, add water, and prepare green pellets;

[0045] The dro...

Embodiment 2

[0053] like figure 1 As shown, a method for preparing oxidized pellets from municipal sludge and iron-containing waste is characterized in that it includes the following raw materials and their mass parts:

[0054] 7 parts of municipal sludge;

[0055] 91 parts of iron-containing waste;

[0056] 2 parts bentonite;

[0057] The water content of the municipal sludge is 35%.

[0058] The iron-containing waste includes blast furnace gas ash, converter sludge, sintering dedusting ash and sulfuric acid slag; the mass ratio of the blast furnace gas ash, converter sludge, sintering dedusting ash and sulfuric acid slag is: 19:17:33:31 .

[0059] Carry out the following steps with the above raw materials:

[0060] 1) Mix the weighed raw materials; the mixing process uses a mixing truck with a rotating speed of 20r / min and a time of 5min.

[0061] 2) Put the mixed raw materials obtained in step 1) into a disc pelletizer, add water to prepare green pellets; the prepared green pellet...

Embodiment 3

[0069] Such as figure 1 As shown, a method for preparing oxidized pellets from municipal sludge and iron-containing waste is characterized in that it includes the following raw materials and their mass parts:

[0070] 9 parts of municipal sludge;

[0071] 90 parts of iron-containing scrap;

[0072] 1 part bentonite;

[0073] The water content of the municipal sludge is 35%.

[0074] The iron-containing waste includes blast furnace gas ash, converter sludge, sintering dedusting ash and sulfuric acid slag; the mass ratio of the blast furnace gas ash, converter sludge, sintering dedusting ash and sulfuric acid slag is: 23:21:28:28 .

[0075] Carry out the following steps with the above raw materials:

[0076] 1) Mix the weighed raw materials; the mixing process uses a mixing truck with a rotating speed of 18r / min and a time of 6 minutes.

[0077] 2) Put the mixed raw materials obtained in step 1) into a disc pelletizer, add water, and prepare green pellets; the prepared gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com