Hinge joint connecting structure of hollow slab bridge

A hollow slab bridge and hollow slab technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of increasing construction procedures, increasing construction difficulty, and prolonging construction period, so as to increase materials and workload, and reduce the impact of veneer damage. force problem, the effect of providing carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

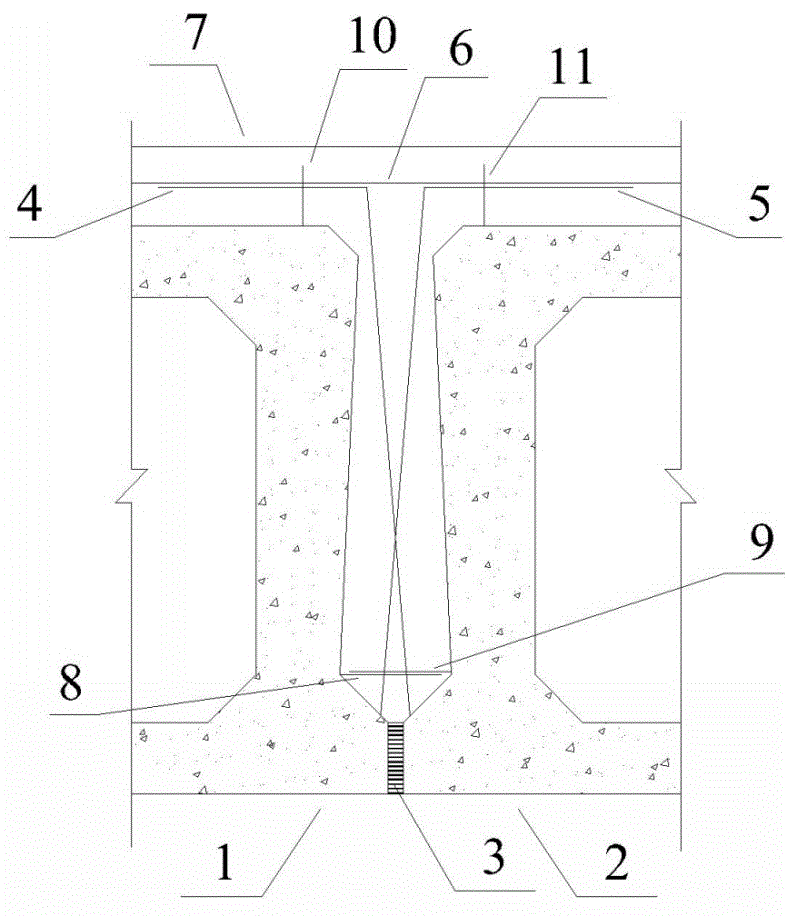

[0027] A schematic cross-section of a hinged joint structure of a hollow slab bridge and a schematic diagram of its reinforcement arrangement are shown in figure 1 and figure 2 . The two adjacent hollow plates include the hollow plate (1) on the left side of the hinged joint and the hollow plate (2) on the right side of the hinged joint. It is filled with elastic sealant. The horizontal connecting steel bar (8) protruding from the seam between the protrusion of the left hollow plate and the web overlaps with the horizontal connecting steel bar (9) protruding from the joint between the protrusion of the hollow plate and the web on the right, and their respective The distance between the front end and the root of the other party (that is, the junction between the bump and the web) is 1 cm. The root of the obliquely connecting steel bar (4) protruding from the hollow slab bump on the right side of the hinge joint and the obliquely connecting steel bar (5) protruding from the ...

Embodiment 2

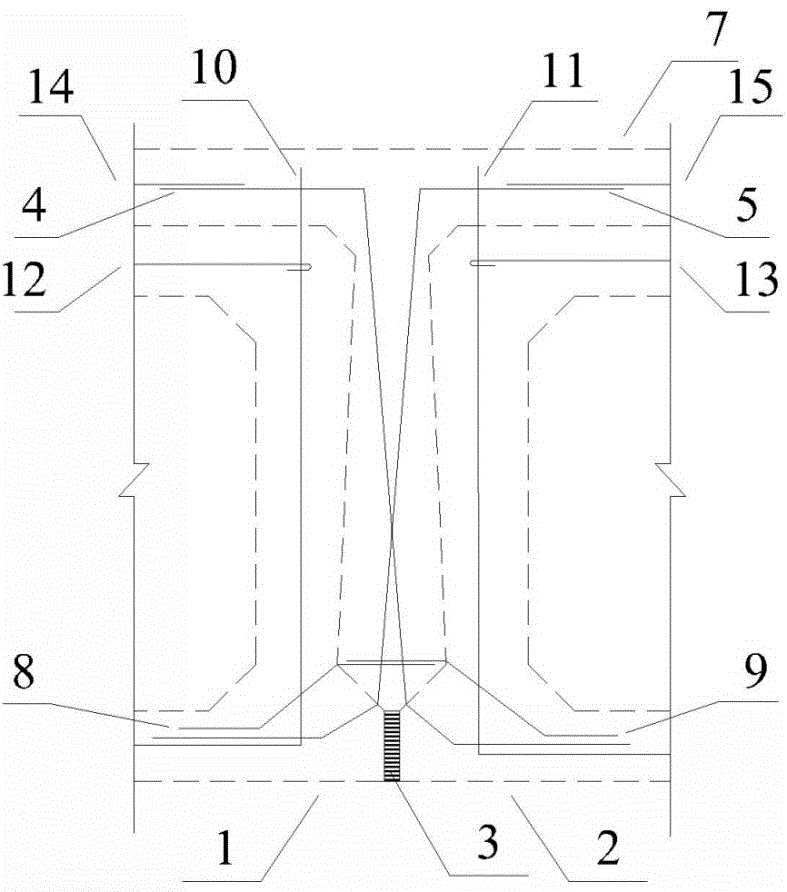

[0029] This implementation example is an amendment to the implementation example 1. For the relevant reinforcement layout diagram, see image 3(The transverse reinforcement in the deck pavement is not shown in this figure). The gap (3) between the lower end bumps of adjacent hollow plates is filled with a two-component chemical slurry, which reacts after mixing, and the volume expands rapidly during the reaction process, and the formed elastic sealing material has internal stress inside, which is called The material is expanded polymer. Place the reinforcement section (14) above the left hollow slab connected to the cross reinforcement and the reinforcement section (15) connected to the cross reinforcement above the right hollow slab above the top slab of the hollow slab at the same height as the reinforcing bars in the pavement. The horizontal section of the cross reinforcement is welded to the section of the reinforcement. The bottom of the cross reinforcement is welded in...

Embodiment 3

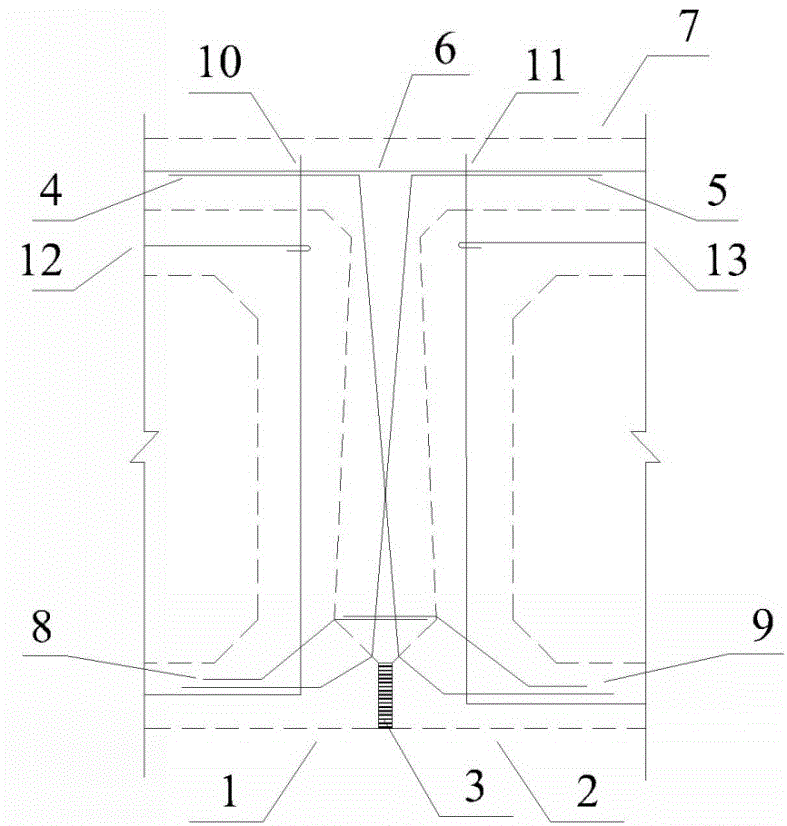

[0031] This embodiment is also a modification to Embodiment 1, and the relevant reinforcement layout schematic diagram is shown in Figure 4 . In order to facilitate construction and transportation, and to avoid too much corrosion due to the exposure of cross steel bars, and increase the workload of rust removal, the oblique connecting steel bar (4) protruding from the hollow plate bump on the right side of the hinge joint and the hollow plate on the left side of the hinge joint The oblique connecting steel bar (5) protruding from the bump only stretches out 25 centimeters of the bump when the hollow slab is prefabricated, and is connected with the rest of the cross reinforcement sections by a sleeve before installation on the construction site. Use the horizontal steel bar (12) on the left side of the hollow slab roof and the horizontal steel bar (13) on the right side of the hollow slab roof in the prefabricated hollow slab as the connecting steel bars connecting the crossin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com