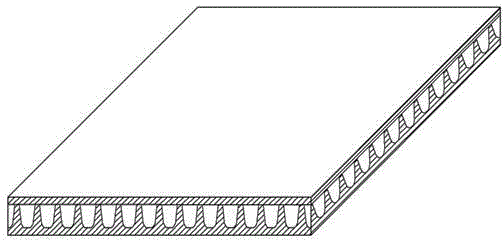

Honeycomb circular-arc-shaped plastic template

A plastic formwork and honeycomb technology, applied in the field of polymer plastic formwork for construction, can solve the problems of insufficient turnover times, high cost, heavy formwork weight, etc., and achieve the effects of weight reduction, good weather resistance and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

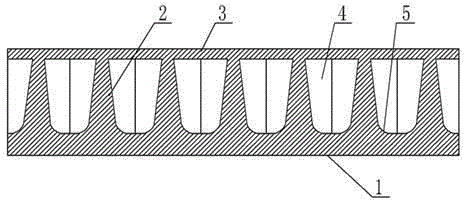

[0016] The bottom plate 1 and the ribs 2 are formed at one time.

[0017] The ribs 2 have a certain thickness and height, are staggered vertically and horizontally, are connected end to end, and are in a solid convex shape.

[0018] The panel 3 is combined with the large end face of the rib 2.

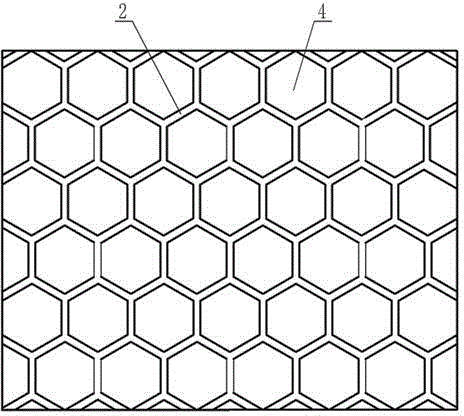

[0019] The honeycomb cavity 4 is an equilateral hexagonal cone cavity.

[0020] The transition arc 5 is a transition arc between the small end surface of the equilateral hexagonal cone cavity and the cone surface of the equilateral hexagonal cone cavity.

[0021] The cavity of the equilateral hexagonal cone has a small end face on the bottom plate 1 and a large end face on the panel 3.

[0022] The said equilateral hexagonal cone cavity is each equilateral hexagonal cone cavity and the adjacent six equilateral hexagonal cone cavities, the large end surface and the large end surface have the same distance, and the small end surface and the small end surface have the same distance.

[0023] The thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com