Deep-refrigerating liquid air energy storage system with air stage intercooling

A liquid air and interstage cooling technology, which is applied in refrigeration and liquefaction, liquefaction, multi-stage pumps, etc., can solve the problems of high operating cost and low efficiency of circulating energy storage, and achieve the purpose of increasing the stored internal energy and reducing the energy consumption of the compressor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

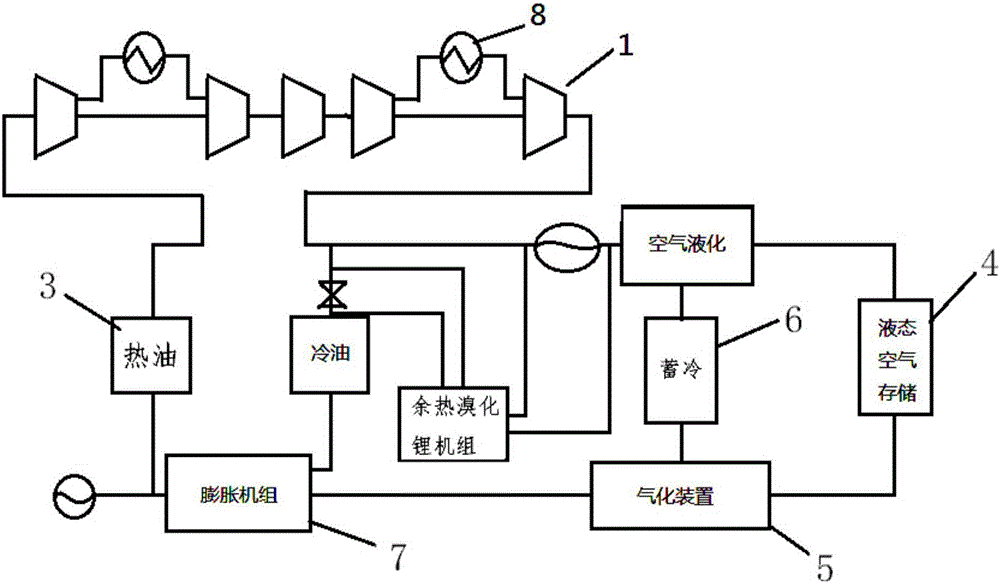

[0034] This embodiment provides a cryogenic liquid air energy storage system with air interstage cooling, the following combination figure 1 The energy storage system of this embodiment is described in detail, which includes:

[0035] The air compressor unit 1 includes several stages of air compressors to compress the low-temperature and low-pressure air into high-temperature and high-pressure gaseous air;

[0036] The heat energy recovery device 3 collects the heat energy generated during the air compression process;

[0037] The liquid air storage tank 4 stores the high-temperature and high-pressure liquid air;

[0038] The gasification device 5 is used to gasify the high-temperature and high-pressure liquid air into high-temperature and high-pressure gaseous air, and receive the heat energy stored in the heat energy recovery device 3;

[0039] The cold energy recovery device 6 collects the cold energy generated during the gasification of liquid air into gaseous air, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com