Non-refrigeration broadband infrared detector

An infrared detector and broadband technology, applied in the direction of electrical radiation detectors, etc., can solve the problems of complex structure of infrared detectors, narrow infrared absorption band, unable to realize broadband, etc., to achieve excellent infrared detection performance and improve infrared absorption rate. , the effect of low-cost infrared detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

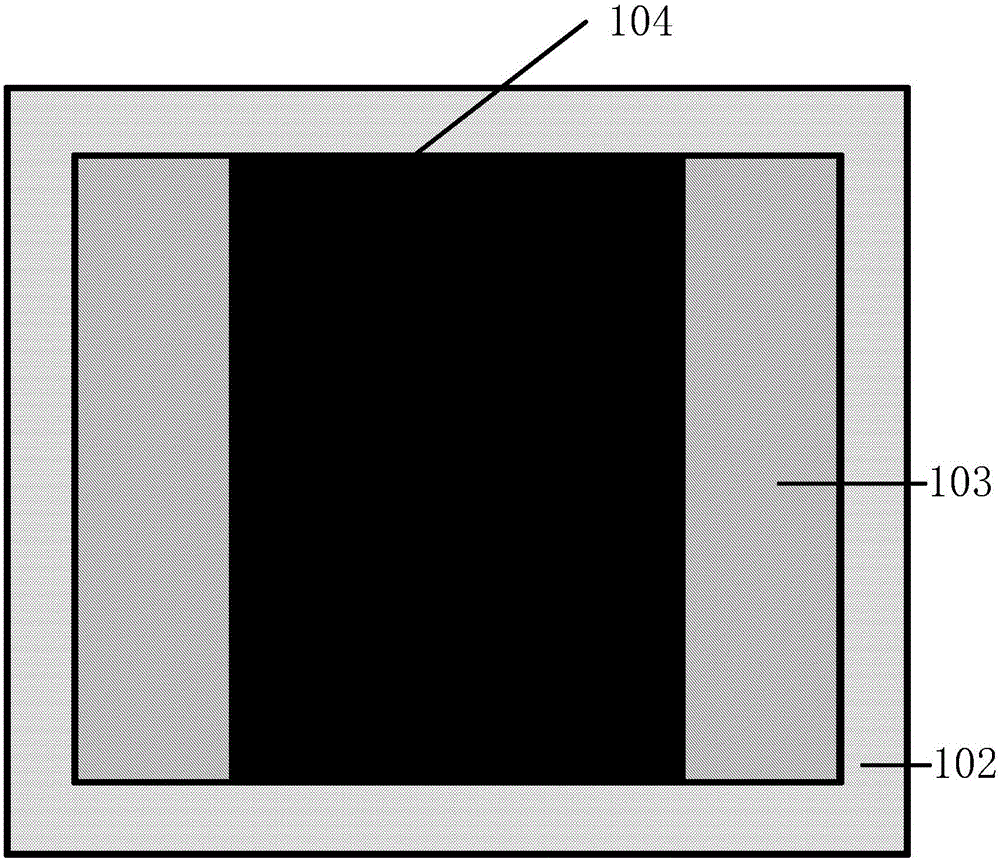

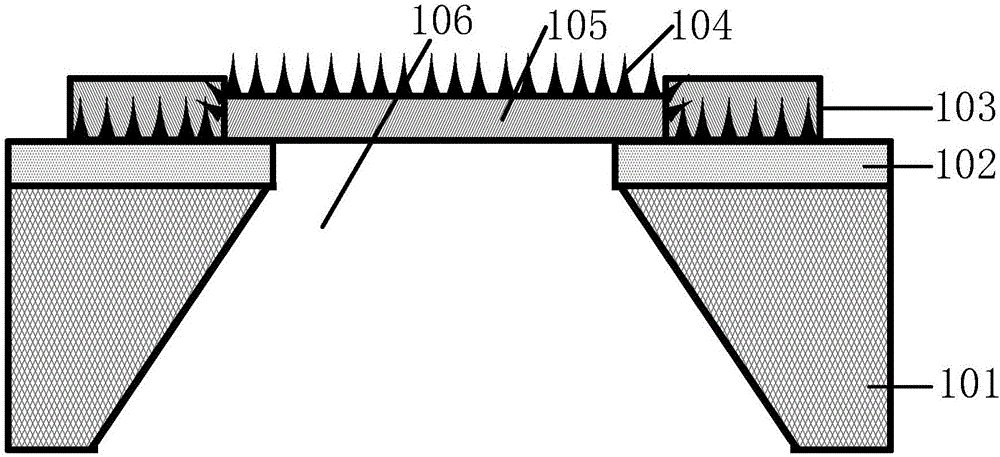

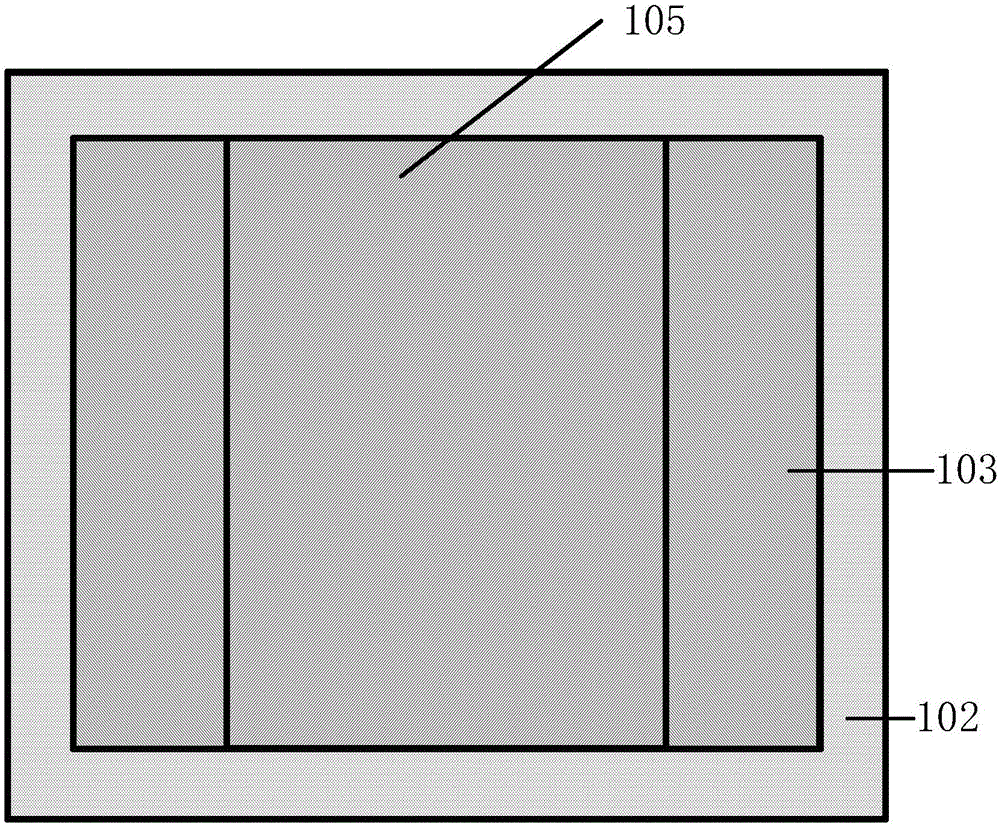

[0046] An uncooled broadband infrared detector, the top view of its unit device structure is as follows figure 1 As shown, the cross-sectional view of the unit device structure is shown in figure 2 shown.

[0047] An uncooled broadband infrared detector in this embodiment, its unit device includes a silicon substrate 101 , a support layer 102 , a metal electrode 103 , a broadband infrared absorbing layer 104 , a heat sensitive layer 105 and a floating hole 106 . The broadband infrared absorbing layer 104 is placed above the heat sensitive layer 105, and the heat sensitive layer 105 is located in the middle of the broadband infrared absorbing layer 104 and is in contact with it; the metal electrodes 103 are placed on both sides of the heat sensitive layer 105, and the broadband infrared absorbing layer 104 above the two ends, and in contact with the broadband infrared absorption layer 104; the support layer 102 is placed above the silicon substrate 101, and the suspended hole...

Embodiment 3

[0057] An uncooled broadband infrared detector, the top view of its unit device structure is as follows figure 1 As shown, the cross-sectional view of the unit device structure is shown in figure 2 shown.

[0058] An uncooled broadband infrared detector in this embodiment, its unit device includes a silicon substrate 101 , a support layer 102 , a metal electrode 103 , a broadband infrared absorbing layer 104 , a heat sensitive layer 105 and a floating hole 106 . The broadband infrared absorbing layer 104 is placed above the heat sensitive layer 105, and the heat sensitive layer 105 is located in the middle of the broadband infrared absorbing layer 104 and is in contact with it; the metal electrodes 103 are placed on both sides of the heat sensitive layer 105, and the broadband infrared absorbing layer 104 above the two ends, and in contact with the broadband infrared absorption layer 104; the support layer 102 is placed above the silicon substrate 101, and the suspended hole...

Embodiment 4

[0068] An uncooled broadband infrared detector, the top view of its unit device structure is as follows figure 1 As shown, the cross-sectional view of the unit device structure is shown in figure 2 shown.

[0069]An uncooled broadband infrared detector in this embodiment, its unit device includes a silicon substrate 101 , a support layer 102 , a metal electrode 103 , a broadband infrared absorbing layer 104 , a heat sensitive layer 105 and a floating hole 106 . The broadband infrared absorbing layer 104 is placed above the heat sensitive layer 105, and the heat sensitive layer 105 is located in the middle of the broadband infrared absorbing layer 104 and is in contact with it; the metal electrodes 103 are placed on both sides of the heat sensitive layer 105, and the broadband infrared absorbing layer 104 above the two ends, and in contact with the broadband infrared absorption layer 104; the support layer 102 is placed above the silicon substrate 101, and the suspended hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com