Air jets protruding from seawater on the bottom of a ship

An air jet and ship technology, applied in jetting device, jetting device, hull and other directions, can solve the problems of reduced air discharge chamber binding force, inability to polish the surface, corrosion, etc., to improve water tightness and air tightness, improve adhesion performance, The effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

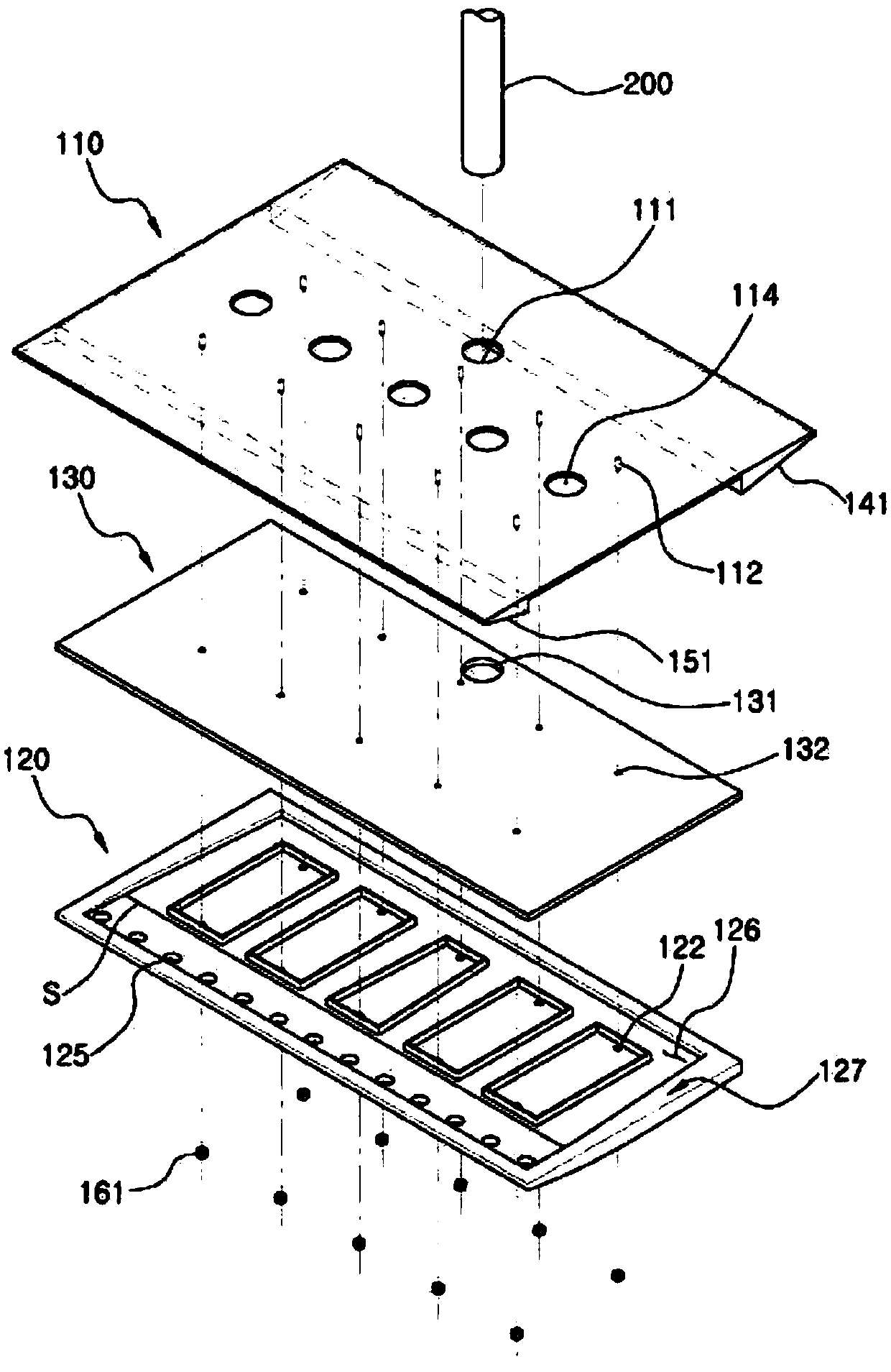

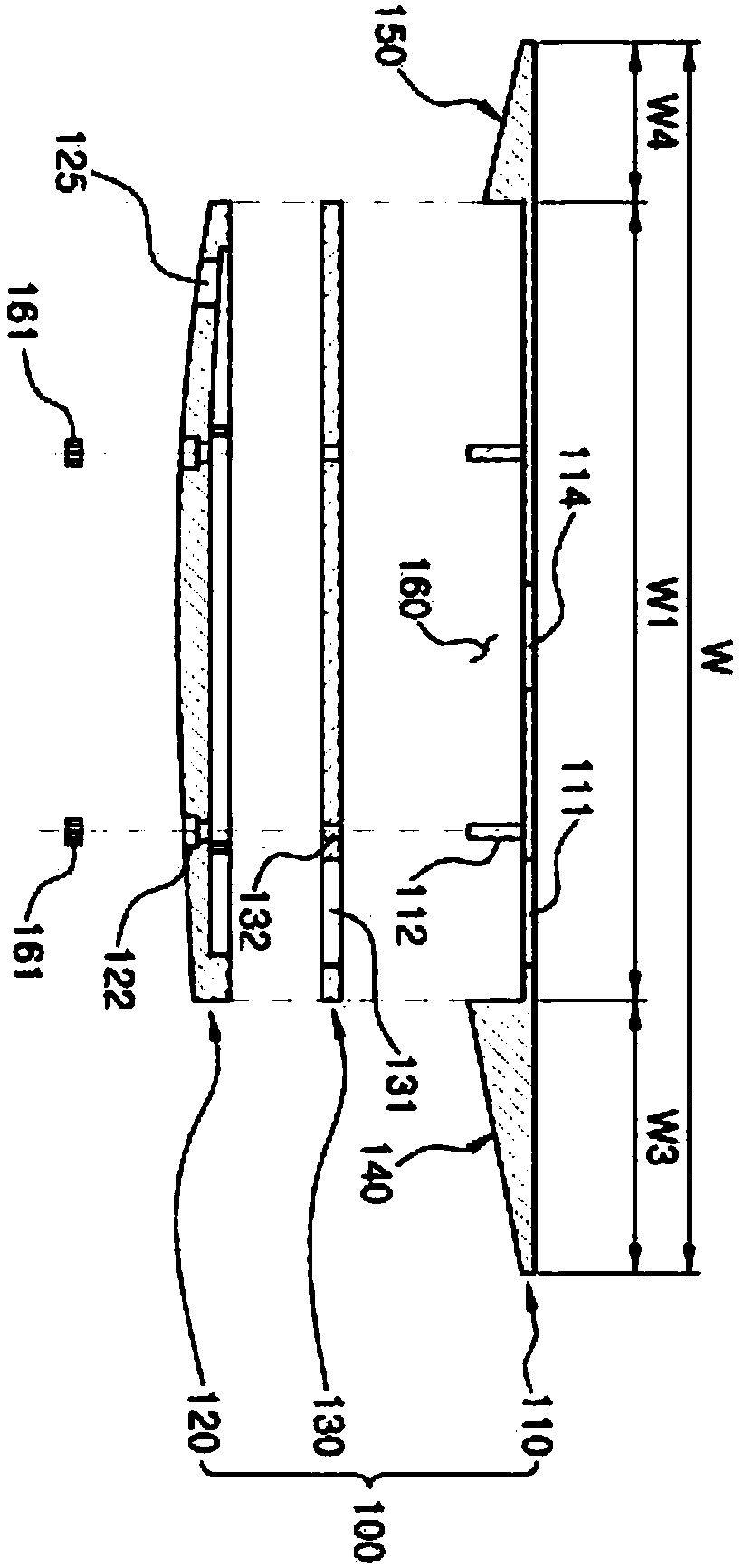

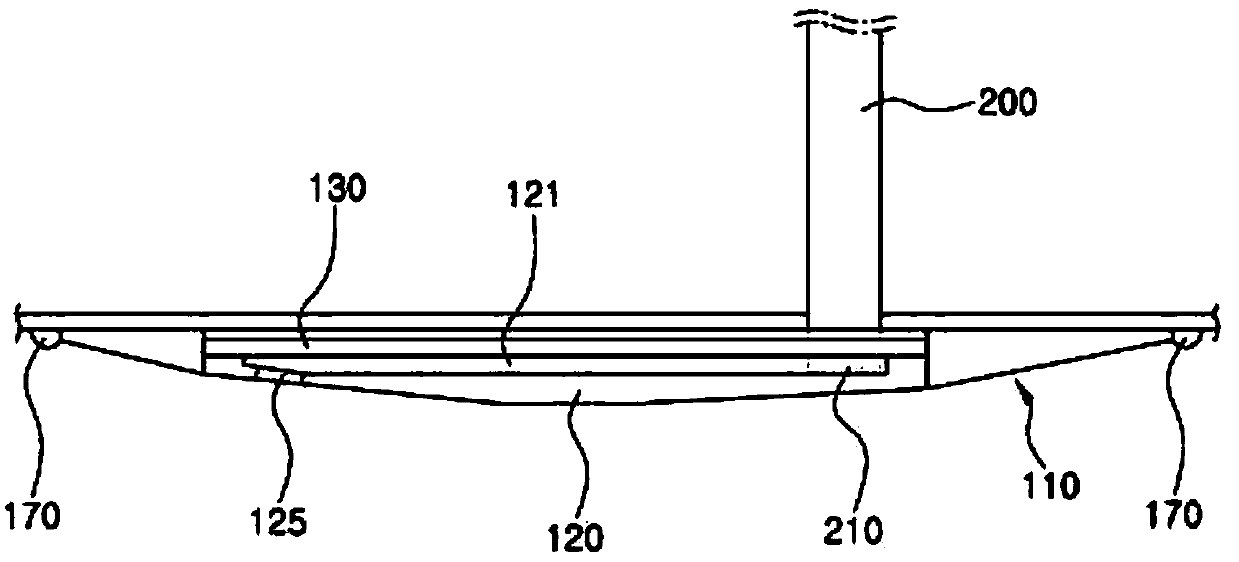

[0050] figure 1 It is an illustration figure (exploded view) showing the structure according to the present invention, figure 2 is an illustration diagram showing a combination relationship according to the present invention, image 3 It is an illustration diagram (combined diagram) showing the constitution according to the present invention, Figure 4 is an illustration showing the composition of the base plate according to the present invention, Figure 5 is an illustration showing the structure of the air injection plate according to the present invention, Figure 6 yes means Figure 5 An illustration of the A-A cross-section configuration, Figure 7 is an illustration showing the flow of air in the air flow path according to the present invention, Figure 8 is an illustration showing the composition of the connecting plate according to the present invention, Figure 9 It is an illustration of the bottom surface of a ship showing the installation state of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com