Method for improving femtosecond laser processing accuracy

A femtosecond laser processing and precision technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

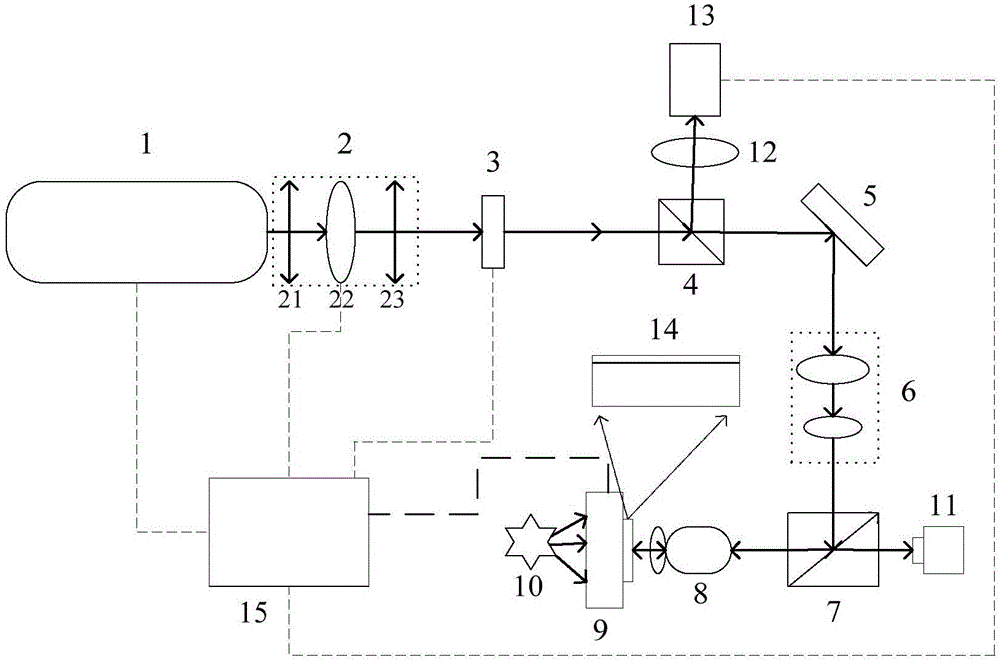

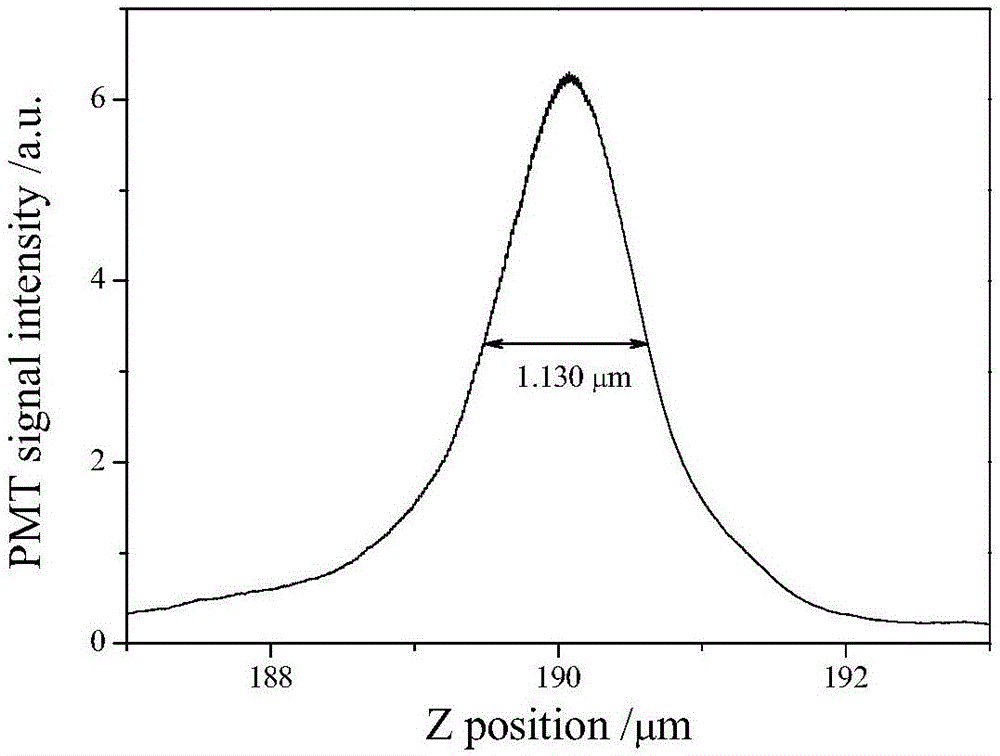

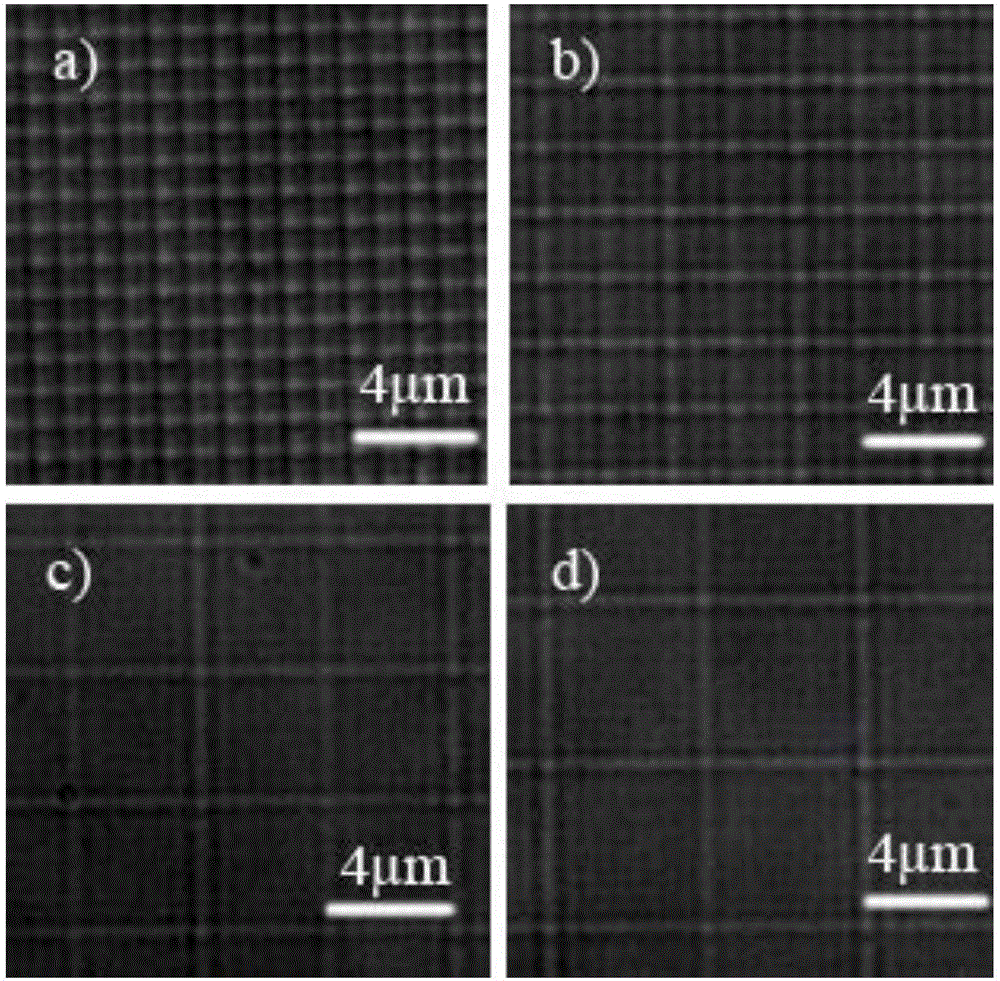

[0028] Embodiment 1: a method for improving the precision of femtosecond laser processing, the processing equipment is set as figure 1The shown sample distance detection device detects the distance of the sample 14 to be processed placed on the processing equipment before the femtosecond laser processing through the sample distance detection device, thereby improving the accuracy of the femtosecond laser processing; the sample distance detection device includes A laser 1 for emitting a processing beam, a laser power tuning mechanism 2, a shutter 3, a first polarization beam splitter prism 4, a total reflection mirror 5, a laser beam diameter adjustment system 6, a second polarization beam splitter prism 7, The objective lens 8 and the three-dimensional mobile platform 9 for placing samples, the laser power tuning mechanism 2 is composed of a first polarizer 21, a wave plate 22 and a second polarizer 23, the power tuning accuracy is 1 μW, and the laser beam diameter adjustment s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com