A kind of biaxially stretched polymer film and its preparation method and application

A polymer film, biaxial stretching technology, used in chemical instruments and methods, synthetic resin layered products, lamination, etc. -30°C, complex preparation methods, etc., to achieve the effects of dimensional stability, structural stability, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

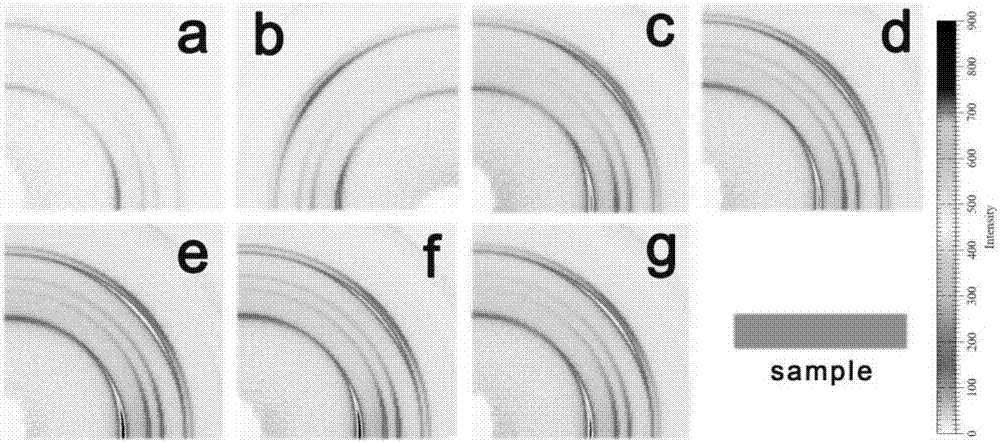

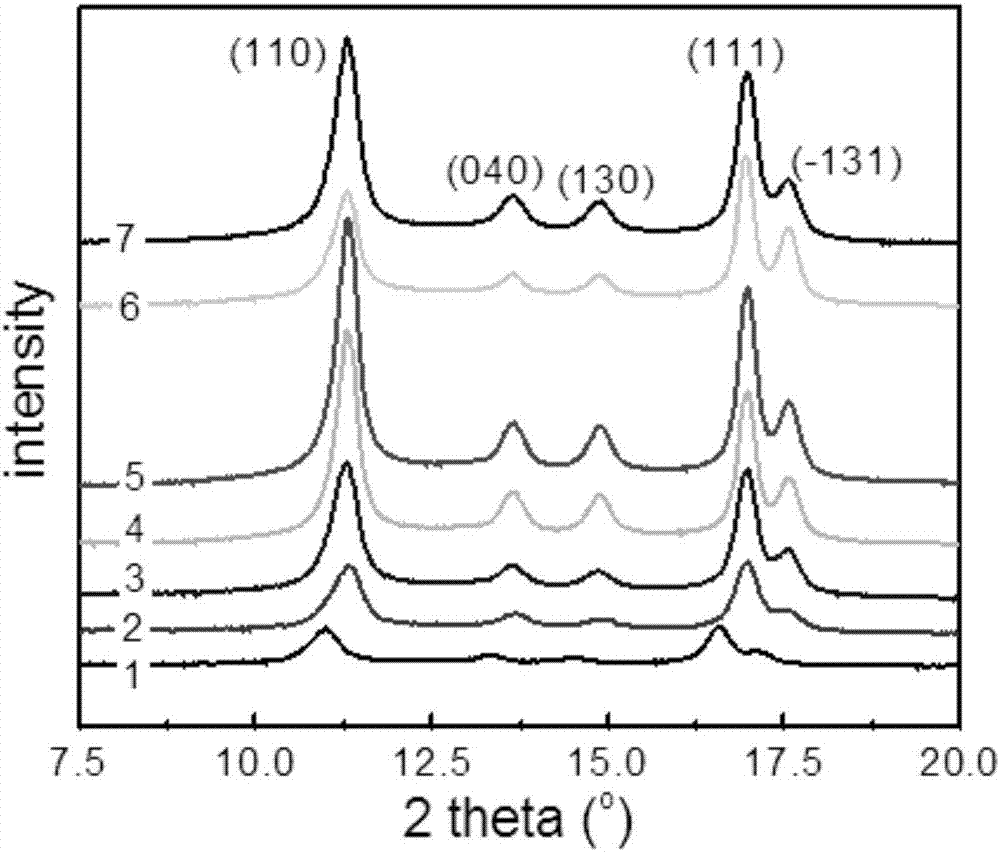

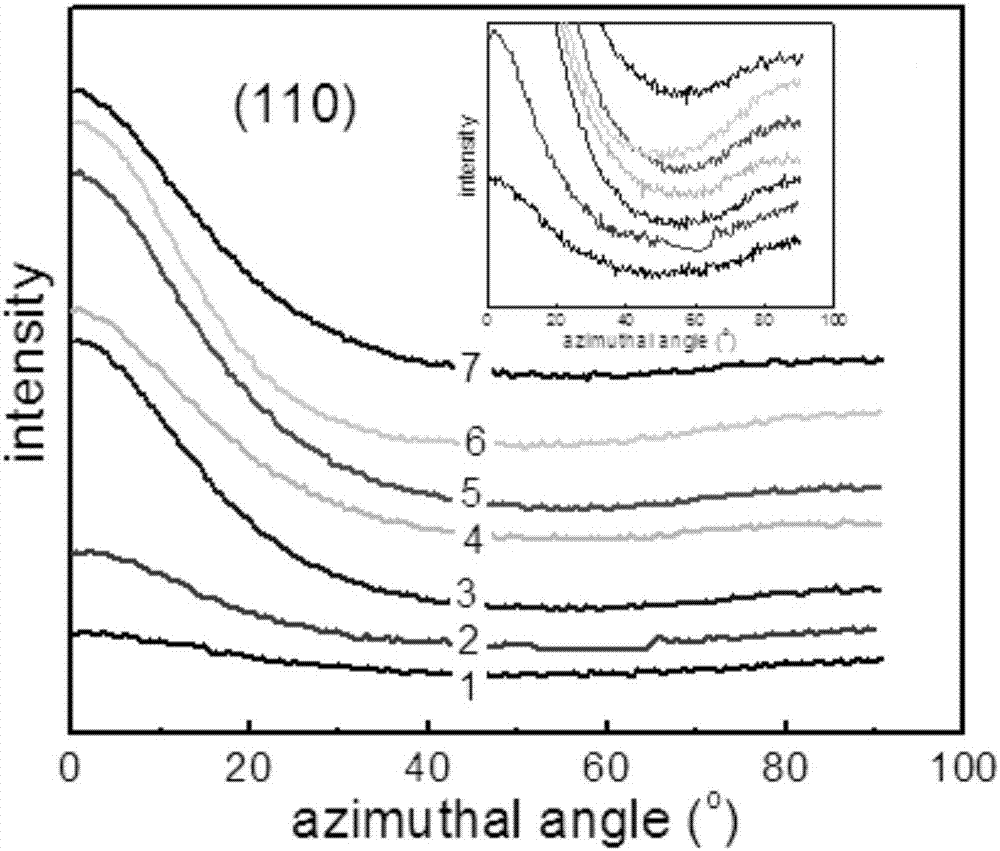

Image

Examples

Embodiment 1

[0074] (1) The raw material of base film layer is put into extruder, wherein said raw material contains polypropylene 75%, silica 12%, butadiene-styrene random copolymer 8%, matting agent two Silicon oxide 5%, wherein the temperature of the extruder is 150 ° C; the raw material of the adhesive film layer is put into an auxiliary extruder, and the extrusion temperature is 200 ° C;

[0075] (2) The above raw materials are extruded after being melted and plasticized, and flow through a T-shaped die to form a composite layer co-extruded thick sheet. The working temperature of the die is 180°C, and the obtained thick sheet is cooled and formed by a cooling roller and a water tank. The temperature of the cooling roll and the water tank is 20°C;

[0076] (3) Preheat the above slab with a heating roller at a temperature of 1000° C., stretch it longitudinally by 5 times, and stretch it transversely at a temperature of 180° C. and stretch it 6 times;

[0077] (4) After double-sided cor...

Embodiment 2

[0080] (1) The raw material of base film layer is put into extruder, wherein said raw material contains polypropylene 80% by mass percentage, glass microsphere 12%, butadiene-styrene random copolymer 8%, wherein The temperature of the extruder is 180°C; the raw material of the adhesive film layer is put into an auxiliary extruder, and the extrusion temperature is 250°C;

[0081] (2) The above raw materials are extruded after being melted and plasticized, and flow through a T-shaped die to form a composite layer co-extruded thick sheet. The working temperature of the die is 200°C, and the obtained thick sheet is cooled and formed by a cooling roller and a water tank. The temperature of the cooling roll and the water tank is 30°C;

[0082] (3) Preheat the above slab with a heating roller at a temperature of 150° C., stretch it longitudinally by 6 times, and stretch it transversely at a temperature of 200° C. and stretch it 9 times;

[0083] (4) After corona treatment on one sid...

Embodiment 3

[0086] (1) Put the raw material of base film layer into the extruder, wherein said raw material contains ethylene propylene copolymer 85% by mass percentage, nano silicon dioxide 2%, vinyl chloride-vinyl acetate copolymer 8%, extinction 5% silicon dioxide, wherein the temperature of the extruder is 250°C; the raw material of the adhesive film layer is put into an auxiliary extruder, and the extrusion temperature is 300°C;

[0087] (2) The above-mentioned raw materials are extruded after being melted and plasticized, and flow through a T-shaped die to form a composite layer co-extruded thick sheet. The working temperature of the die is 250°C, and the obtained thick sheet is cooled and formed by a cooling roller and a water tank. The temperature of the cooling roll and the water tank is 20°C;

[0088] (3) Preheat the above slab with a heating roller at a temperature of 200° C., stretch it longitudinally by 8 times, and stretch it transversely at a temperature of 200° C. and stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com