Self-navigating ultra-large offshore steel structure floating body and manufacturing method thereof

A technology of autonomous navigation and manufacturing methods, which is applied in the direction of ship construction, floating buildings, ship parts, etc., can solve the problems of inability to complete the construction at one time, high production cost, low work efficiency, etc., and achieve safe and controllable launching process. Ease of adjustment and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

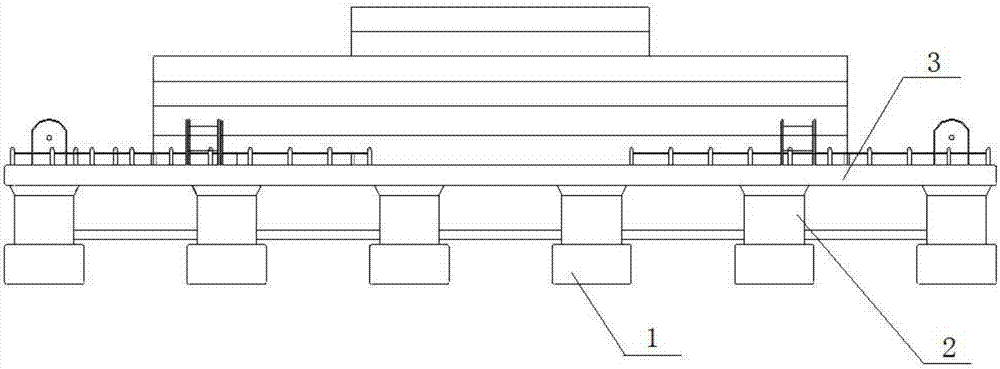

[0034] Attached below Figure 1-2 The present invention is described further:

[0035] An ultra-large offshore steel structure capable of autonomous navigation, including a bottom floating body, a middle supporting frame structure 2 and a top platform structure 3, the middle supporting frame structure 2 is fixed on the upper surface of the bottom floating body, and the top platform structure 3 is fixed on the middle supporting frame structure 2.

[0036] The bottom floating body has a width of 100 meters and includes a plurality of floating tanks 1 arranged at equal intervals. The floating tanks 1 are hollow structures with both ends closed, with a width of 8 meters, a height of 4 meters and a length of 1000 meters.

[0037] The middle support frame structure 2 is a strong frame composed of steel frames, steel pipes, and brackets, with a height of 6 meters.

[0038] The top platform structure 3 is 1000 meters long, 100 meters wide, and 2 meters high. The top platform structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com